Analysis covered techno feasiblity of the proposed investment and recommended investment of a Fully Composite and Integrated Commercial Egg Producing Farm –Agro Industry,

Current Investment Policy of the Government and related industrial development

Poultry is a substantial contributor to food supply of Bangladesh. Many small and medium farmers are rearing poultry birds in Bangladesh. Bangladesh is considered as one of the most appropriate countries in the world for poultry rearing. Development of poultry has generated considerable employment through the production and the marketing of poultry and poultry related products. A group of entrepreneurs and professionals headed by Syed Fazle Rabbi, Managing Director, of Globe Essentials Limited and Globe Enterprises & Agencies Limited, & Atlas Greenpac Limited, (Bangladesh Companies), and Mr. Md. Wahidur Rahman, a renowned businessman and entrepreneur leading Feaz Group, and other business professionals with extensive local and international experience intends to invest in a Fully Composite and Integrated Egg Producing Farm – Agro industry for sales to ever growing demand within Bangladesh. The industry will be located in Rangpur Sadar and adjacent areas in 5 Locations. The company named “ATLAS FARMS LIMITED” has been established with a paid up capital of Taka 30.00 Million ans land has since been acquired for the projects. ATLAS FARMS LIMITED shall use the most sophisticated Egg Layer houses where mature hens live in fully environmentally controlled houses, including, heat, cold, humidity, clean controlled air, and artificial ligting and music. Our farms will have the feed supplied from silos by conveyors, water by nipple feeders, the litter will be taken out by conveyors and eggs will also be collected by specially design conveyors and belts to controlled egg rooms for packaging. ATLAS FARMS LIMITED’s Supply Management marketing system will allow us to maintain these farm units and businesses where, as owners and operators, we personally oversee the care and health of our birds. It’s also permitted us to effectively specialize and realize many benefits, including greater productivity and lower costs.

Objective of the project

The main objective of the report is to develop a poultry farm and its financial forecast which can successfully establish brand image in consumers mind and position the product in the market. The specific objectives of the report are given below:

- Analyze information on the Products to be manufactured

- Analyze Market information.

- Project cost and Projected investment

- Doing survey and find out the consumer demand of the products

- Computing Financial aspects

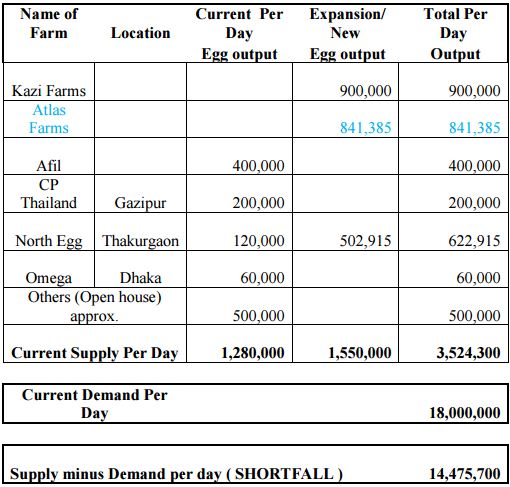

Competitive Analysis:

Modern Layer Farms in Bangladesh

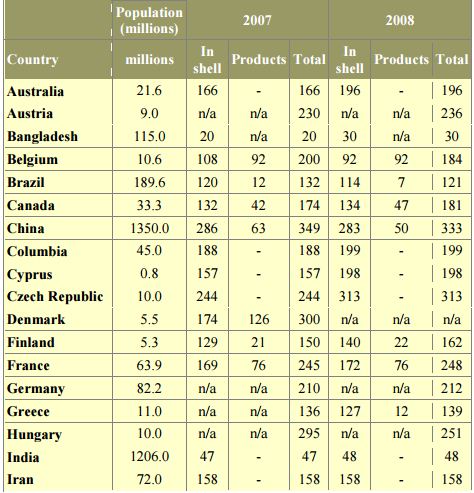

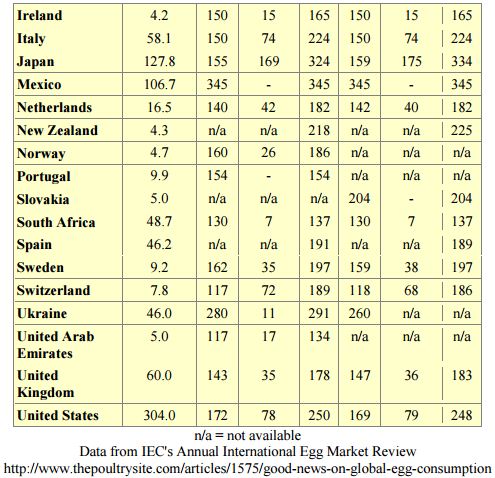

Per Capita Egg consumption by Country:

Egg consumption per person continues to rise.

Most of the member countries of the International Egg Commission (IEC) reported either stable or increased egg consumption per person last year (see table below).

Mexico regained the number one spot from China, which slipped to third place behind Japan. However, it should be noted that there is considerable scope for errors in the way the data is compiled and differences of just a few eggs per person per year may not be significant.

In several instances, the data – compiled from information received from IEC reporters in the member countries – indicates the consumption of egg products as well as that of shell eggs in the total figures. The Japanese consume the largest number of eggs in product forms, the total being equivalent to 175 shell eggs per person.

An analysis by Peter van Horne the IEC’s economist, presented in the Commission’s International Egg Market Annual Review, broadly reveals that in Europe, egg consumption falls between 150 and 300 eggs. Uptake is particularly low in Finland and Ireland but high in Denmark and Hungary.

Outside Europe, consumption is spectacularly high at more than 300 eggs per person in Japan, China and Mexico. While the uptake/person is low in India, at just 48 eggs, when this figure is applied to the large human population of 1.2 billion, this country becomes the third largest hen egg producer in the world, behind China and the USA!

Despite large and increasing demand of eggs and other protein sources, the uptake of eggs per person is very low in Bangladesh although the increasing trend will be observed as more supplies are ensured to meet demand.

With high population, low per capita income although increasing due to increased agriculture inputs and production, industrialization and repatriation of funds from Bangladesh workers abroad; demand for egg and food in general shall accelerate

Decreasing fish resource due to extreme affects of environment, pollutants in rivers due industrialization, egg will become the choice of the most economic protein for the mass population in addition to pulses (daal). It is projected that the Poultry sector will be thrust sector of Bangladesh.

Egg consumption in IEC member countries (number/person/year)

Many factors influence egg consumption levels including culture, tradition, income and religion. On the aspect of income he has shown that, in many countries (north-west Europe, Canada, New Zealand and Australia) where the gross national income per person ranges between US$20,000 and $40,000, egg uptake is between 150 and 300 per person per year.

However, he said: “Many countries with a lower average income have similar egg consumption, for example Argentina and Thailand where uptakes average between 150 and 180 eggs/person. However, while China and Mexico have relatively low average incomes their egg consumption is very high.

“Probably consumer preferences with special dishes and other food traditions influence consumption in these countries. The low consumption in India possibly relates to religion, as a large sector of the population does not eat any animal products, including eggs.”

However, he stresses that further research is needed to clarify differences in consumption between countries, which would be particularly relevant to forecast future consumption levels, as incomes will increase in most countries in the years to come.

Conclusion

The demand of eggs in Bangladesh is increasing with continued development of the country with increased GDP as well as Govt. policy on Agriculture, Industrial output and strengthening the Labor and manpower sectors alongwith additional inputs and supports for farmers. However, supply is short and without further investments in moder farms their will remain an acute shortage of eggs.

INVESTMENT OPPORTUNITY

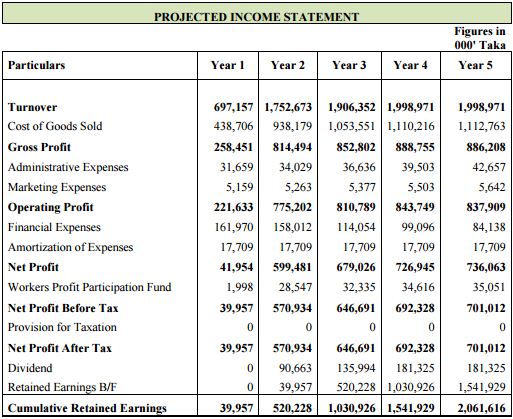

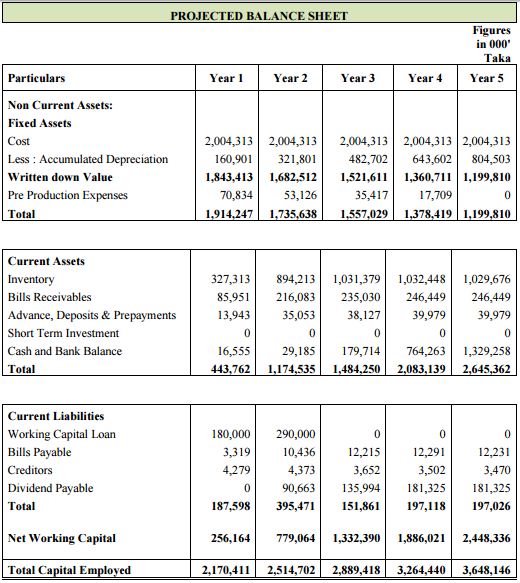

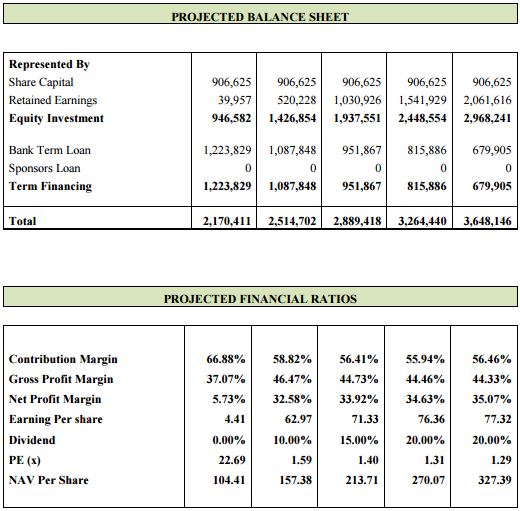

Following table-shows the position of Investment.

Project Preview Q&A

How Are Eggs Produced?

Every day we are bombarded with news and views about food. Advertisements, health experts and reporters tell you about calories, fat, food safety and balancing your diet.

Occasionally, even the way food is produced makes the news. The media will focus on a food processor, a new product or technology. Every once in a while there will be a story about crop failures, animal husbandry or the environmental challenges that agriculture faces.

So, it’s natural that the Bangladesh Citizens have lots of questions about the food they eat. ATLAS FARMS LIMITED shall produce high quality fresh eggs every day. We not only plan to be the most sophiticated and technologically advanced industry, we also plan to do so by carefully balancing our business needs, the wholesomeness of our product and the welfare of our Chicken birds.

Our Sponsors, Investors, Financiers, other stake holders, Government Agencies, NGO’s and Bangladesh Consumers have questions. We have our response.

Introducing the Egg

Let’s start with some information about our product.

Eggs — we call them a natural source of goodness. Why?

Usually, it’s because of the fact that eggs contain so many nutrients. But, as producers, we believe it’s also because eggs are wholesome, delicious, easy to use, versatile and such good value. They are an excellent source of the high quality protein needed for human growth and development.

Eggs contain all nine essential amino acids, making them one of the few foods with complete proteins. In fact, the pattern of amino acids found in eggs is so perfect for our bodies that scientists use eggs as the standard to measure the protein quality of other foods.

In addition to protein, eggs contain a significant number of the vitamins and minerals we need.

From just one large egg, you can get 25 percent of your daily requirement of vitamin B12, 13 percent of your vitamin D and 9.5 percent of your vitamin A.

Then there are the minerals — iodine, phosphorous, magnesium, iron and zinc. Eggs do all this, yet each large egg has only 75 calories and a small quantity of fat (five grams), only 1.5 grams of which are saturated. The fat in eggs are useful too. It provides a compact source of energy, assists the human body to absorb fat-soluble vitamins (A, D, E, K), makes important hormones and helps produce the acids our digestive system needs to do its work.

An Egg Is An Egg, Isn’t It

ATLAS FARMS LIMITED shall produce eggs for eating and eggs for hatching. The difference is that hatching eggs are fertilized and will produce a chick. Table eggs produced by us will however be unfertilized and shall come to the marketplace for consumption as an egg.

From our Breeder Layer Farm most of the chicks from hatching eggs will produce approx 50:50 male and female chicks referred as day old chicks (DOC). The male chicks will be sold to small farmers who shall raise the chicks and sell them as broilers destined for consumption as meat by Bangladesh consumers in their homes or in restaurants.

The female chicks will be raised in our farms until they are at age to start laying fertilized aggs. These eggs will be set in modern incubators, and chicks shall be hatched artificially. We have selected hy-line brown as the most popular breed of chicken for egg production. It’s a small,

Yes! and, No!

ATLAS FARMS LIMITED shall produce eggs for eating and eggs for hatching. The difference is that hatching eggs are fertilized and will produce a chick. Table eggs produced by us will however be unfertilized and shall come to the marketplace for consumption as an egg.

From our Breeder Layer Farm most of the chicks from hatching eggs will produce approx 50:50 male and female chicks referred as day old chicks (DOC). The male chicks will be sold to small farmers who shall raise the chicks and sell them as broilers destined for consumption as meat by Bangladesh consumers in their homes or in restaurants.

The female chicks will be raised in our farms until they are at age to start laying fertilized aggs. These eggs will be set in modern incubators, and chicks shall be hatched artificially. We have selected hy-line brown as the most popular breed of chicken for egg production. It’s a small, light bird that lays far more eggs than its ancestors. Its eggs are brown.

Consumers prefer brown eggs although some like those with white shells. Still, white or brown, there is no difference in nutritional value or cooking performance. In this case, an egg is an egg.

The benefits that we derive from eggs, however, go beyond food. Eggs are also used to make highly specialized products for use in medicine and science.

Flu and measles vaccines, for example, originate with eggs. Hospitals use eggs in diagnostic tests to identify some viruses and diseases. Pharmaceutical products, extracted from egg whites, are used as tools to deliver drugs to tumours. Still others are included in over-the-counter health products like eye drops, toothpaste and throat lozenges to fight bacteria. The exceptional characteristics that make eggs such a natural source of goodness in our diets are finding many other important and beneficial uses. In these cases an egg is more than an egg.

Food From The Farm

Poultry Farms in Bangladesh are changing dramatically. They’re fewer in number, bigger in size and more productive. Farms are more mechanized and, computerized.

A modern farm requires lots of capital, up-to-date techniques and skilled, knowledgeable farmers. An increasing number of producers have university or other post-secondary education. In our business, success is a direct result of lifelong learning and innovation.

Most agricultural production takes place on specialized farms. That’s not to say that farmers restrict themselves to just one product — wheat or dairy cattle or eggs. Many farms are complex, multi-enterprise businesses. It’s just that, today, very few farms have a few hens, some chickens, a goat or two and some cows for milk.

The farm products you consume come from either plants or animals. Bangladesh consumers should value the choices they have to achieve a balanced diet and Food Guides recommends a variety of products from the major food groups as being essential to good nutrition.

The mixed farm disappeared long ago. It’s been replaced by well managed operations that specialize in only one or, at most, a few types of products.

Farmers within animal agriculture, too, have specialized to meet demand for meat or animal products such as milk and eggs.A few modern Bangladesh egg operations, for example, commonly have between 30, 000 and 50, 000 hens on the farms at any one time.

However, in the United States, concentration is even greater. South of the border, egg production has become big business. During the past 20 years, the number of producers has declined sharply from over 10, 000 to under 1, 000 and just one-third of these supply 94 percent of the eggs.

Indeed, the top seven egg companies each have more than five million laying hens in their farms and the largest controls 19 million.

ATLAS FARMS LIMITED’s Supply Management marketing system will allow us to maintain these farm units and businesses where, as owners and operators, we personally oversee the care and health of our birds. It’s also permitted us to effectively specialize and realize many benefits, including greater productivity and lower costs.

Our unique marketing system will create opportunities to successfully develop this country’s capacity to produce food while establishing and maintaining a high standard of care for the land we use and the chickens we raise.

So, Just What is Involved in Producing Eggs

Putting that fresh, nutritious egg in the refrigerated counter at the supermarket or in a Bazaar is a complicated and fascinating business. It’s changed a lot in the past hundred years, but in many respects, it’s still very much the same.

Where Does it Start? With Poultry Breeding!

We could get into that old riddle about which comes first, the chicken or the egg, but it really makes more sense to start with the breeding stock.

On specialized farms in Bangladesh and elsewhere, the traditional breeds of chickens, Hy-Line Brown, White Leghorns and others, have been raised, crossbred and improved. Poultry breeders work with the whole industry to ensure that the hens destined to produce eggs for consumers here have just the right characteristics.

The wild ancestors of today’s laying hens came from Asia. Like many other birds, they lay a small number of eggs, usually five to eight in the springtime.

Domestication of the chicken started about 3,000 years ago but most of the improvements made in poultry breeding have come in this century. In 1910, a good hen could be expected to lay about seven dozen or 84 eggs a year. By the 1950s, production was up to about 150 per year. Today, thanks to genetic improvements, the typical hen lays more than 285 eggs a year.

Breeders take great care in running their operations. A new cross or strain, with the characteristics in demand by the competitive world marketplace, can have considerable value. That means special attention is paid to disease prevention through the implementation of high standards of care and strict biosecurity programs.

Careful attention is also paid to the preservation of biodiversity. Breeders are aware of the need to preserve the genetic diversity of chickens for the future.

With the selection of the basic breeding stock or “grandparents” by a breeder, the cycle of production moves into its next stage. Eggs are hatched and chicks are raised to maturity for the production of hatching eggs. These chickens become the parent stock of the hens.

What’s Next? Hatching Egg Production!

On a hatching egg farm, the birds mature through four clearly defined stages. First comes brooding. During the initial three weeks, careful attention is paid to the environmental conditions in the barn. Temperature control, preventing drafts and ensuring availability of feed and fresh water are vitally important to the young chicks. A lot of producer time is invested and the level of care is high.

The second stage, from three to 19 weeks, is often called the growing period. Next comes the prelaying period, from 19 to 24 weeks. It covers the changeover from growing to when the breeder female can produce hatching eggs.

Good management during these periods is the best assurance for efficient performance of the breeding flock.

Operators focus on proper feeding and lighting programs. Feed quality, energy level, protein quality and quantity are also carefully monitored and adjusted to ensure a proper nutritional balance.

Careful attention is paid to all aspects of the breeding flock’s health. Many operators work closely with veterinarians to develop a flock health program that involves vaccinations against common diseases. These programs are especially important as they can positively influence the immunity of the next generation of chicks.

The First Crack is The Chicks! At The Hatchery

From the cool of the hatching egg storage to the heat of the hatchery incubator, that’s the next step in producing the egg.

The centerpiece of the modern hatchery, the incubator, has come a long way from the primitive type. More often than not, it’s now a series of large stainless steel, computer-controlled and monitored cabinets capable of hatching thousands of eggs at a time.

Incubators are usually electrically or hot water heated to keep the temperature constant. Fresh air is circulated continuously. But a constant temperature, good ventilation and constant humidity are not the only priorities at the hatcheries. Other environmental controls, especially disease prevention and sanitation, are equally important.

Eggs remain in incubators for 18 days when they are transferred to a hatching cabinet. When hatched, the chicks are carefully removed from the hatchers.

Then, the chicks are vaccinated and prepared for shipment with 24 hours to the pullet-grower farms where they will spend the next 19 weeks.

Why Are Their Beaks Trimmed

Sometimes prior to the eleventh week, the pullets’ beaks are trimmed. Some prefer to do it when the chicks are quite young. Others wait until the birds are older. However, in all cases, it’s in the producer’s best interest to ensure that this procedure is completed quickly, accurately and under the best conditions.

The reason being for beak trimming in quite simple. As they mature, young hens become increasingly aggressive and use the sharp end of their beaks to establish a pecking order in the farm. Beak trimming keeps the birds healthy.

Beak trimming is a highly specialized task performed by trained professionals. Sanitation and the prevention of infections are a priority.

The pullet grower’s objective is to ensure that healthy chicks mature into healthy layer hens. Poultry geneticists have found that it may be possible to breed hens whose aggressive behaviour is significantly reduced. Other researchers have found that changing some environmental conditions, particularly lighting, can also have an impact. These options may has now become a commercial reality as ATLAS FARMS LIMITED shall incorporate and follow the latest technical innovations in it’s Farms.

Now Where Are Those Eggs? The Laying Operation

At about 19 weeks of age, the pullets are transferred from the pullet farms to laying houses. This is done with considerable care as a significant investment has already been made in each hen.

The Modern Farm

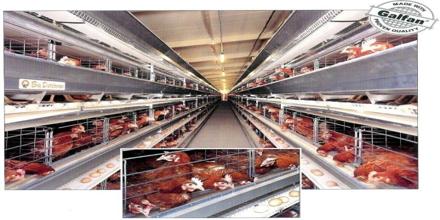

The facilities that will house the mature laying hens for the full year have also changed dramatically from our grandparents’ time. The hen house with straw on the floor has been replaced by a modern multi tier cages in large laying houses.

On our egg farms, the houses with its collection and storage facilities represents our greatest capital investment. Driving down a country highway, you probably wouldn’t recognize our farms.

But, if you look closely, they will be distinguished by the presence of long rows of ventilation fans on one side and ducts on the other.

Maintaining a healthy farm environment will allways be a high priority to us. We shall use the latest in computer-controlled ventilation systems to ensure air circulation and temperature control, both heating and cooling. That’s because one of the greatest challenges any egg producer is to climate control each houses.

With temperatures falling in the winter and rocketing into the high heat and humidity in summer, egg producers have to build well insulated barns and install the best cooling systems.

In Bangladesh, two types of housing are common. ATLAS FARMS LIMITED shall use the most sophisticated Egg Layer houses where mature hens live in fully environmentally controlled houses, including, heat, cold, humidity, clean controlled air, and artificial ligting and music. Our farms will have the feed supplied from silos by conveyors, water by nipple feeders, the litter will be taken out by conveyors and eggs will also be collected by specially design conveyors and belts to controlled egg rooms for packaging. However, a majority of local small and medium scale egg farms are open houses and use aviary systems where the hens are allowed full use of the barn floor or a series of pens within it. However, environment, feed, litter cannot be totally controlled and diseases are rampant.

Cages — Why do We Use Them?

The majority of internationally known farms and egg producers have adopted unit housing, which is common to almost all industrialized countries, for a number of reasons.

Cages:

- ensure a safe supply of eggs;

- provide better access to feed and water;

- reduce illness;

- permit easy cleaning and higher hygiene standards.

Safer Eggs

ATLAS FARMS LIMITED, as the most modern, integrated farm to be established in Bangladesh has put food safety at the top of our list of priorities. Using units to house our hens is one key to our Start Clean-Stay Clean Program for food safety. This program is designed to keep the bacteria found in the environment — in soil, water, animals and insects — away from eggs.

Controlled housing units makes a difference.

Modern housing systems are designed to ensure that the eggs, hens, and manure are kept apart. The manure falls through holes in the unit floors and is removed by conveyor belts. The cages are also designed so the eggs roll away from the hens and into a separate egg collection system. Then, they are gently and automatically moved and delivered to the central packing area.

Producers and hens no longer engage in a game of hide and seek for eggs in the straw beds or litter on the farm floor.

Healthier Hens

ATLAS FARMS LIMITED shall also use housing units for Chicken welfare reasons. We want our flocks to be healthy and productive. Our livelihoods and the success of our farms depend on it.

With cage systems, it’s easier to meet this priority. Access by the birds to the feeders and drinkers is convenient and assured.

In addition, the units provide protection against predators and from the negative social or behavioural effects of congregating large numbers of birds.

ATLAS FARMS LIMITED shall incorporate a code of practice for handling poultry. It will set out recommendations for a wide range of humane production practices from handling chicks to housing hens. We shall carefully follow these guidelines when we install our housing systems.

The most popular housing systems stack three to nine rows of cages, one on top of the other. ATLAS FARMS LIMITED has selected 5 tiers for easy management of birds without need to use hoists. This makes for the efficient placement of the egg collection and manure removal equipment. It also permits the design of wide aisles which facilitates cleaning and assures effective monitoring of the flock by the producer.

Sizes and the number of hens per unit vary depending on the type and the age of the system installed by the producer. Most systems have a lifetime of between 25 and 35 years. They are expensive and represent a significant investment.

What Happens to The Hen?

After about 12 months of egg production, hens begin to lay eggs with thin shells. The hens are gently removed from their cages and transported to processing facilities.

New cage design with wide doors will be ordered by ATLAS FARMS LIMITED as these will allow the birds to be gently removed.

At the processing facility, the hens are humanely slaughtered. They are then further processed, usually as stewing hens, ready for the soup pot or the curry, or as processed meat products.

Where’s The Egg?

When that fresh egg had just been delivered by a conveyor belt to the central packing area of the egg barn. Here it is placed in a plastic, sanitized flat, wide end up, to keep the yolk centered.

These flats are then placed on pallets, stored immediately in a cooler where the temperature is maintained at 11° to 12° C. In the cooler, eggs retain their freshness and quality while awaiting shipment to clients.

Our inspectors will take random samples of the cartoned eggs to verify the grading process and ensure that high quality standards are maintained. Government Food Inspection Agency inspectors may also check on the sanitation and operating procedures at our farms to ensure that the eggs shipped to stores, restaurants and food manufacturers are of the highest quality.

Additionally, our graders, shall check if the eggs are candled: they’re passed over a strong light which makes the interior of the egg visible, allowing the grader to thoroughly examine the egg. To be he best Grade, the egg must have a thick white, a well centered yolk, a very small air cell and a clean, sound shell.

Eggs we produce may be processed into liquid, frozen and dried form in the future and as per market demand. These processed eggs are used in the manufacturing of many foods from mayonnaise to noodles and baked goods. Some of them are used to make other items such as health care products, shampoo, pet foods and adhesives.

Eggs are sized according to their weight and placed in recyclable fibre, foam or plastic cartons. They are then stored in a separate refrigerated room.

Eggs are delivered to the grader’s where the storage rooms are temperature and humidity controlled. We may in the future install automated grading line where suction cups gently lift the eggs out of the flats onto a moving track. On the track, they are washed and sanitized in a high speed tunnel washer.

The Next to Last Stop

The attention that’s been given to careful handling, quality and environmental control doesn’t stop at the grader’s shipping door. Retailers and restaurants will be recommended to refrigerate eggs at 4° C immediately upon delivery and follow first in, first out procedures for stocking the store counters or using the eggs in the kitchen. This ensures that the eggs you buy are always fresh.

The Last Stop

The last stop is with the consumer. where all food must be handled properly to ensure it remains of the highest quality. Store eggs in the refrigerator and in the carton they were purchased in. The

cartons were designed for egg storage and they help to keep the eggs fresher, longer. Also, to maximize freshness, store the egg with the wide end up. Hygiene and kitchen cleanliness are important when preparing food. Make sure your hands, utensils, countertops and cutting boards are washed. Also, make sure your dish cloths and towels are freshly laundered.

SITE / LOCATION

Address

Factory: Rangpur Sadar and adjacent area

Particulars of land:

- Total Area : 47 Acre

- Area required for the project : 47 Acre

INFRASTRUCTURE

All type of infrastructure facilities, electricity etc. are available at project site. This site is well connected by road and highways. The site is surrounded by plantations and vegetation at all sides, and the environment is “clean and green “, a pre-requisite for egg producting farms – Agro Industry.

From all strategic point of view the site is an excellent choice for such project.

SELECTION OF MACHINERY

All machinery, houses, insubators, systems shall be imported from Germany and the USA with exception of some machinery to be built or procured locally.

The selected modern houses and machinery are incorporated with automation including Process Line Computerization (PLC) or total synchronized operation without the help of human hands. The capacity of these machinery and systems are high and efficient.

A full fledged maintenance workshop will be established within the area. The workshop shall have the requisite equipment required for installation and maintenance of the machinery & equipment.

From the financial analysis on the proposed project we can see that, on implementation the investment on quality machinery will be viable, cost effective and profitable.

Erection and Installation:

Installation and running test to be carried out by the supplier/seller with the help of foreign and local technicians.

Safety & Security:

The project will have adequate safety provision to fight against fire hazards along with all modern equipments.

Pollution & Waste disposal:

The project will have no pollution as litter will be taken out and reprocess as organic fertilizer at a different site.

Implementation schedule:

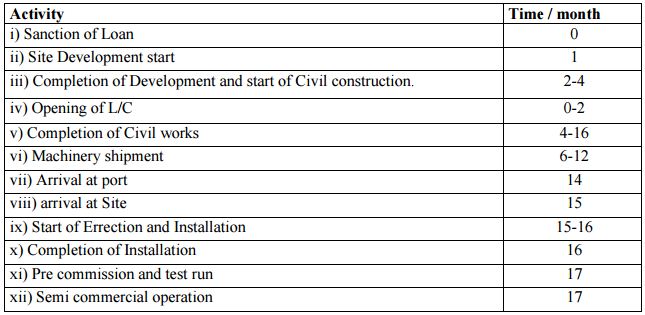

It has been estimated that the project will go into full operation within 18 months from the date of start of construction. It’s schedule shown below:-

Conclusion

Egg production farms planned by ATALS FARMS LIMITED is perhaps a very challenging business. It involves a long chain of people co-operating to make the industry a success. As a poultry breeder dedicated to developing hens with the characteristics best suited to Bangladesh’s environment and consumer needs. Our hatching eggs, hatcheries, feed mills, liter management and organic fertilizer conversion farms and pullet farms reflects our willingness to adapt to the latest in technology, methodology, process, systems and controls available. And, as an egg producer, we shall ensure that the consumers have fresh, high quality eggs at reasonable prices every day. Producing a natural source of goodness for Bangladesh consumers is a matter of pride.

As producers, we’re especially proud that we have been able to plan and to do this carefully by balancing our business needs as farmers, your interests as consumers and the welfare of our flock of chicken.