Main purpose of this report is to discuss Company Analysis on Delta Jute Mill Limited. Other objectives are analysis marketing activities of jute mills to determine the marketing approaches like pricing method, promotion system overseas. Here also discuss on government regulation on a pvt Limited organization we need to know how the government regulate the financial or business organization. Finally find out the lickings of the company and observe how companies run their operation.

Introduction

For country’s economy jute and production of jute goods are highly important. Jute is a golden fiber of Bangladesh. In past, jute was the main export product of our country.

Delta jute mills Limited” is an organization that had been playing an important role for the economy from the Pakistan period. We have the privilege to visit such organizations a part of our study tour and got the opportunity to analyze the operation of the organization in real and very closely.

Delta jute mills Limited was established on 1963.late Al-haz abdur rab was the founder of this mill. In Pakistan period this jute mill was the only private Limited mill.

This mill was completed in the year 1965. Production of the mill has been started in June 1965.

It is the biggest amount the Bengali owner’s mill. The area of mill land is 60 acres.

The mill has got 2 gas turbine generators of 750 k.w. capacity of each producing power to run the mill from 1988 and since then no production loss occurred for want of power.

Main objectives:

We are the students of marketing, which mostly involves tasks of business. So, for our improvement of our knowledge and experience we have come across such study or survey. We can point out some of them.

- To get real experience and getting real experience might have helped as to administrative own job.

- To know marketing activities of jute mills to determine the marketing approaches like pricing method, promotion system overseas

- To know government rules it’s a private Limited organization so there is light government ruling. To know the government role on such economically beneficial organization.

- To know government regulation on a pvt Limited organization we need to know how the government regulate the financial or business organization.

- To get practical knowledge in the 21st century to remove unemployment which is a major problem in Bangladesh?

- To find out the lickings of the company.

- To observe how companies run their operation.

Jute Mills in Bangladesh: An overview

Jute grows under wide variation of climatic conditions and stress of tropic and subtropics. It is grown in Bangladesh, India, Myanmar, Nepal, China, Taiwan, Thailand, Vietnam, Cambodia, Brazil and some other countries. Bangladesh used to enjoy almost a monopoly of this fiber commercially; its share in the export market was 80% in 1947-48 but in 1975-76 it fell to only 25%. This fall in the world market was due to the fact that many countries had started growing jute and allied fibers. The substitutes of jute are multiwall paper bags, poly-propelling, polyethylene, and natural fibers from knead, hemp, sida, sunhemp, etc. Jute fibers are used in hessians and gunnies, carpet and rugs, paper, canvas, tarpaulin, handicrafts, etc. Dundy (UK) purchases high class jute of all grades, particularly white and tossa. Belgium, Italy, USA, South America are the buyers of superior quality jute.

Jute was cultivated in ancient times in Bengal. At that time it was more or less a garden plant and its leaves were used as a vegetable and for medicinal purposes. Jute grows well where the annual rainfall is 1500 mm or more, with at least 250 mm during each of the months of March, April and May. Jute is cultivated in the rainy season. In Bangladesh sowing usually starts at the end of February and continues up to the end of May, depending on the species. Cultivation largely depends upon pre-monsoon showers and moisture conditions. C. capsularis is more water tolerant and thus generally can be grown in low lands, and even under water logging conditions, while C. olitorious is more susceptible to water logging and hence cultivated in medium to lower medium lands. Jute can be grown in a number of soil types, ranging from clay to sandy loam with optimum fertility, and soil pH ranging from 5.0-8.6.

Jute is basically self-pollinated and has fourteen diploid chromosomes. It needs long day light for growth. After sowing, four to five months are needed for harvesting of crops. This is done at the flowering stage. The fiber is obtained from the bust or phloem layer of the stem. Jute cultivation is labor intensive and is mostly grown by marginal, poor, and small landowners. For successful cultivation, land preparation is very important. It needs 3-5 times cross ploughing and laddering for uniform smooth soil, which must have more than 20% organic content. Cow dung is generally used, along with NPK in appropriate proportion, according to the soil type. In Bangladesh farmers generally do not use any fertilizer in jute cultivation. However, when used it must be applied in three stages; one at land preparation, and two as top dressing at appropriate time. During cultivation weeding is usually done in addition to thinning.

Generally, 10-12 kg/ha seed is sown by the broadcasting method. In line sowing, lower amount of seeds is required. Traditionally, farmers keep a small part of the crop area for growing seeds until the seeds mature in October/November. After harvesting, plants are bundled together with required number of plants, and kept standing for 5-7 days in the field for shading off the leaves. Then the bundles are put under water. Clear slow flowing water is the best thing possible for good retting. After 12-15 days, when proper retting is completed, the fiber is separated from the stick by hand and then washed and dried in sunlight. After drying, farmers sell the fiber in the local market.

Jute products Jute and jute-based products are put to a wide range of uses. Since antiquity it has been used as a raw material for packaging. Before being used as a commercial commodity it was used in different parts of the world to make household and farm implements such as ropes, hand made clothes, wall hangings, etc. In Bengal sacks and saris made of jute were commonly used in the Middle Age. Export of sacks started in the 18th century. Its leaves and roots were used as herbal medicine, and as vegetable by the local people. Its use as an industrial commodity began in the Crimean war when it was used as a substitute of flax. Its use was popularized primarily in Western Europe, particularly at Dundee. Traditionally, use of jute products are limited to packaging materials like twine, hessian, gunny bag, twill, carpet backing, wool pack, tarpaulin, mats, canvas, wall cover, upholstery, and as furnishing fabrics of different types and natures.

Jute research Jute being a cash crop, by 1900 a fiber expert was appointed by the government of undivided Bengal at the direction of the India Government. He developed a number of superior varieties like Kakya Bombai, D154 (Dhaka 154), and CG (Chinsurah Green). In 1938, the Indian Jute Research Institute was established at Dhaka and technological laboratory was set up at Tullyganj in Kolkata. Jute research was once again initiated at Dhaka through the creating of the Central Jute Committee in 1951 by the Ministry of Agriculture. A Jute Research Institute was established at Tejgaon, Dhaka, in 1957. Located on Manik Mia Avenue at Sher-e-Bangla Nagar, the Institute is now named as Bangladesh Jute Research Institute.

The Jute Regulation Directorate was established in 1940 by the provincial government for the regulation of the crop. This department was setup to regulate the cultivation and production of jute and to ensure that it was grown in fixed areas and to see farmers did not grow it more areas than assigned. A Jute Board was set up in 1949 which used to regulate the entire jute trade, and was assisted by the Jute Trading Corporation, Jute Price Stabilization Corporation, and Jute Marketing Corporation. In 1973 the Jute Division was created and put under the direct control of the Finance Ministry so that it could look exclusively on various aspects of jute. In 1976 this Division was converted into full-fledged ministry. Now the International Jute Organization has its head office in Dhaka.

Jute Industry played an important role in the economic development of Bengal. At the beginning of the twentieth century, Bengal could boast of only one manufacturing industry – jute. It employed about a half of the total industrial workforce of Bengal. In 1900-1, the export value of jute manufactures accounted for nearly a third of the entire export trade of Bengal. The industry was dominated at the beginning, by Europeans and later, by Marwari’s. During most of its history, three-quarters of the laborers in jute factories were non-Bengalis. Bengalis generally occupied only the intermediate position in the industry. The raw jute for the industry used to come from Eastern Bengal.

Prior to the establishment of the first jute mill in 1855, handloom weavers used jute fiber to make twines, ropes, coarse fabrics for the poor, and also for fishing and for mooring vessels. Towards the end of the eighteenth century, jute attracted the attention of the British east India company, which sent a consignment of jute samples to England in 1791 that were successfully spun by flax machinery. The British also found out means to soften the hard and brittle nature of jute fiber by adding oil and water. This made the fiber more pliable and easily separable, and resulted in the production of a usable thread.

Several historical events were responsible for the growth of the jute industry. In 1838, the Dutch government specified bags made of jute instead of flax for carrying coffee from the East Indies. At that time flax was imported from Russia. But the Crimean War of 1854-56 led to the stoppage of supply of flax from Russia and forced Dundee, the famous jute manufacturing centre of UK, to look for substitutes. In Dundee the flax mills were converted into jute mills. The American Civil War (1861-65), on the other hand, gave further impetus to the jute trade, as supplies of American cotton were much restricted. Since then, the industry did not return to flax or cotton again. The main reason for this permanent shift had been its comparative cost advantage. The jute industry grew rapidly and jute mills were established in many countries, including USA, Germany, France, Belgium, Austria, Italy, Holland, Spain, Russia, Brazil and Bengal. This led to a rapid increase in the demand for jute. The Bengali peasants responded quickly to meet the world demand by increasing the area under jute cultivation.

The outbreak of the First World War led to a rapid increase in the demand for raw jute, since it was used to manufacture sandbags to protect soldiers in trenches and to produce gunny bags for carrying food grain for the army. Inevitably, the price of jute also rose sharply.

Although Bengal, particularly Eastern Bengal, was the main producer of quality raw jute, the first jute mill was established at Risraw near Calcutta on the bank of the Hugli only in 1855, after 20 years of mechanical spinning of jute in Dundee. The delay was due to the non-availability of technical hands and power to drive machines. In 1854, coal mines were opened at Raniganj. Attracted by the easy availability of power, George Auckland, an Englishman established the first jute mill. But he could not make reasonable profits and left the business. In 1859, the Borne Company founded the second mill with spinning and weaving facilities. Unlike the Auckland mill, it started prospering after its establishment. Within five years it doubled its plant size. By 1866, three new mills were established. Between 1868 and 1873, these mills made large profits. Five new companies started in 1874 and eight more in 1875. Thus Bengal experienced a real boom in jute industry towards the end of the nineteenth century.

With the establishment of jute mills, Bengal became a major exporter of sacking bags. Calcutta appeared to be a strong competitor of Dundee and successfully penetrated into Dundee’s hessian market in many parts of the world, including America, primarily because Calcutta had the cost advantage in producing jute goods. Secondly, it was situated in close proximity to the jute growing districts of Eastern Bengal and Assam. Thirdly, it had cheap labor. Fourthly, the mills ran for 15 to 16 hours, and sometimes even for 22 hours daily. This led to a clear advantage of Calcutta manufacturers in monetary terms. Moreover, they could offer a finer quality of jute. In sixty years between 1880 and 1940, the number of mills increased by 5 times, that of looms by about 14 times, of spindles by 19 times, and of persons employed by 11 times (see Table). The growth of the industry was significant during the 20 years between 1900 and 1920. During the Great Depression of 1929-33, the jute industry was severely hit since the demand for jute goods declined drastically throughout the world.

Table Growth of jute industry in Bengal, 1980-2005

| Table -1 : Looms Installed and Operated (BJMC & BJMA) | ||||||||||

| Installed (Operable) | Operated | |||||||||

| Period | Hessian | Sacking | C B C | Others | Total | Hessian | Sacking | C B C | Others | Total |

| 1980-81 | 15040 | 8251 | 2405 | 95 | 25791 | 14060 | 7626 | 2026 | 47 | 23759 |

| 2797 | 1909 | 4706 | ||||||||

| 1981-82 | 14837 | 8437 | 2422 | 95 | 25791 | 13830 | 7938 | 1626 | 47 | 23441 |

| 4512 | 3676 | 8188 | ||||||||

| 1982-83 | 14902 | 8393 | 2432 | 95 | 25822 | 15371 | 6026 | 2234 | 46 | 23677 |

| 1308 | 70 | 1378 | ||||||||

| 1983-84 | 14902 | 8393 | 2491 | 95 | 25881 | 16469 | 5547 | 2308 | 49 | 24373 |

| 1363 | 1363 | |||||||||

| 1984-85 | 15193 | 8179 | 2493 | 76 | 25941 | 15475 | 6605 | 2029 | 48 | 24157 |

| 1165 | 1165 | |||||||||

| 1985-86 | 15462 | 7981 | 2493 | 76 | 26012 | 12946 | 6698 | 1847 | 45 | 21536 |

| 972 | 19 | 991 | ||||||||

| 1986-87 | 15122 | 8337 | 2495 | 106 | 26060 | 14467 | 6439 | 1945 | 88 | 22939 |

| 1040 | 1040 | |||||||||

| 1987-88 | 15120 | 8339 | 2495 | 128 | 26082 | 14803 | 5998 | 1818 | 86 | 22705 |

| 924 | 924 | |||||||||

| 1988-89 | 15120 | 8341 | 2503 | 128 | 26092 | 13305 | 6284 | 1825 | 87 | 21501 |

| 760 | 13 | 773 | ||||||||

| 1989-90 | 14955 | 8420 | 2498 | 147 | 26020 | 12589 | 7351 | 1773 | 98 | 21811 |

| 532 | 8 | 540 | ||||||||

| 1990-91 | 14955 | 8420 | 2498 | 147 | 26020 | 12111 | 5799 | 1943 | 91 | 19944 |

| 158 | 2 | 71 | 231 | |||||||

| 1991-92 | 15029 | 8346 | 2498 | 160 | 26033 | 11051 | 6390 | 1991 | 85 | 19517 |

| 47 | 69 | 116 | ||||||||

| 1992-93 | 15004 | 8371 | 2498 | 169 | 26042 | 9694 | 7192 | 1915 | 97 | 18898 |

| 81 | 81 | |||||||||

| 1993-94 | 14985 | 8390 | 2498 | 174 | 26047 | 9512 | 6313 | 1758 | 108 | 17691 |

| 1994-95 | 14141 | 8095 | 2363 | 152 | 24751 | 9669 | 6180 | 1755 | 98 | 17702 |

| 1995-96 | 14357 | 8124 | 2355 | 155 | 24991 | 8502 | 6346 | 1739 | 89 | 16676 |

| 1996-97 | 14946 | 8424 | 2420 | 155 | 25945 | 8004 | 6666 | 1546 | 83 | 16299 |

| 1997-98 | 14346 | 8424 | 2420 | 146 | 25336 | 7835 | 6930 | 1503 | 85 | 16353 |

| 1998-99 | 14905 | 8485 | 2426 | 154 | 25970 | 7830 | 6314 | 1334 | 73 | 15551 |

| 1999-00 | 14329 | 8083 | 2282 | 154 | 24848 | 7845 | 5683 | 1340 | 77 | 14945 |

| 2000-01 | 14370 | 8113 | 2282 | 173 | 24938 | 6871 | 5348 | 1380 | 65 | 13664 |

| 2001-02 | 14369 | 8089 | 2282 | 206 | 24946 | 6328 | 5614 | 1304 | 59 | 13305 |

| 2002-03 | 12469 | 7026 | 1928 | 255 | 21678 | 5326 | 4937 | 1112 | 34 | 11409 |

| 2003-04 | 12020 | 7068 | 1895 | 277 | 21260 | 4993 | 5168 | 1082 | 75 | 11318 |

| 2004-05 | 12034 | 7082 | 1895 | 321 | 21332 | 4009 | 3976 | 804 | 126 | 8915 |

| 2005-06 | 12305 | 7273 | 1945 | 323 | 21846 | 4278 | 4417 | 953 | 101 | 9749 |

| BJMC | 6232 | 3250 | 1157 | 95 | 10734 | 3143 | 2839 | 741 | 22 | 6745 |

| BJMA | 6073 | 4023 | 788 | 228 | 11112 | 1135 | 1578 | 212 | 79 | 3004 |

Before it was put to industrial use, jute was used mostly for domestic purposes. With the conversion of the Dundee flax mills into jute processing mills, the demand for jute increased manifold in the world. Bengali peasants were highly experienced in jute cultivation and could respond quickly to meeting this increased demand.

In 1872, when industrial use of jute had begun, it was mainly grown in the districts of pabna, bogra, darjeeling, dinajpur, rangpur and Hugli (West Bengal). The ratio of land under jute cultivation to total cropped land in these districts in 1872 was 14%, 11%, 9%, 7%, 6% and 5% respectively. Subsequently, jute cultivation spread to other districts. In 1914, leading districts in terms of the above ratio were Rangpur (28 %,) Bogra (25%), Tippera (comilla, 24%), Pabna (21%), Dhaka (18%), Faridpur (16%), Hugli (West Bengal, 13%), Rajshahi (11%), Jessore (10%), Nadia (10%), and Dinajpur (7%).

After the end of the First World War in 1918, the world demand for raw jute decreased. This had a negative impact on the area under jute cultivation. The situation worsened for jute cultivation during the Great Depression of 1929-33. The prices sank so low that jute growing became unprofitable. As a result, peasants greatly reduced their area under jute cultivation. By 1939, economic recovery took place. The breaking out of the Second World War caused an increase in the demand for jute and between 1939 and 1945; peasants put more areas under jute cultivation.

After the Partition of Bengal in 1947, it was found that all jute mills of the region fell in West Bengal, which became a part of India and all major jute growing districts became part of East Bengal, a province of Pakistan. Because it had no jute mills, East Bengal faced problems in marketing of raw jute. The problem was, however, quickly overcome by establishing jute mills in East Bengal.

The jute industry in the public sector, by virtue of its location in East Pakistan, became the property of Bangladesh after independence in 1971. Pakistani mill owners (about 68% of the total loom strength) left the country, leaving the industry in disarray. Abandoned jute mills were subject to heavy looting. The new government of Bangladesh had to take up the responsibility of rebuilding the industry. By a nationalization order, about 85% of industries, including all jute mills, were nationalized.

Bangladesh Jute Mills Corporation (BJMC) was formed to manage and look after all the 73 jute mills having 23,836 looms at that time. At one stage the number of jute mills under the jurisdiction of BJMC went up to 78. BJMC had to resurrect the industry from a ruined position. Immediately after liberation, it became very difficult to solve problem of financial hardship of the jute industry because financial institutions were not working well. Frequent power failures and power stoppages also compelled the industry to suffer heavy losses in terms of production and foreign exchange earnings. In addition to these problems, the short supply of spares, labor unrest, wastage in production etc. also shook the industry severely.

For jute industry of Bangladesh, the first two years after liberation was the period of reorganization. The government offered cash subsidy to the industry, which amounted to Tk 200 million annually. The annual cash subsidy was reduced to 100 million since 1976-77. Thanks to this policy and periodic devaluation of currency, Bangladesh could retain its position of a prime exporter of jute goods in the dollar areas of export. The industry earned profit in 1979-80, when the subsidy was withdrawn. By December 1979, BJMC had 77 jute mills, two carpet backing mills, and two spare parts producing units. In 1980, six twine mills were disinvested to the private sector. In June 1981, BJMC had 74 mills under its administration. These mills had about 165,000 workers and 27,000 managerial and office staff.

Denationalization of jute mills started in July 1982. The government ordered BJMC to complete the process by 16 December 1982, but only 10 mills could be handed over to Bangladeshi owners by that time. The valuation process and settlement of other organizational matters relating to handing over of the mills took a long time. Among the jute mills owned by BJMC, 46 had satisfactory financial performance in 1982-83, when their profit before contribution to national exchequer was about Tk 240 million. The same mills incurred total losses of about Tk 430 million in the previous year. Jute mills incurred losses regularly over years and external donor agencies pressed hard for denationalization. More and more mills were put into the denationalization list. In 1999, BJMC had 33 mills. The World Bank continued to work closely with the government to restructure the jute sector, especially through denationalization, merger, dissolution, closure and setting up of new units.

By 1998, BJMC had an accumulated loss of more than Tk 28 billion and a debt of more than Tk 11 billion. Losses incurred by BJMC in 1997-98 were Tk 2.38 billion. Major features of the BJMC mills in that year were: total production capacity – 451,707 tons; looms in operation – 12,350; loom hours – 59.3 million; production per loom hour – 5.33 kg; baled production – 312,000 tons; consumption of raw jute – 319,306 tons; local sales – 29,000 tons; export 256,000 tons; value of total sales (including export bonus) – Tk 8.5 billion; production cost per ton – Tk 30,349; wages paid to workers – Tk 3.89 billion; and salary paid to employees and executives – Tk 881 million.

Major problems of the jute mills are: (a) increase in the cost of production while the sales prices of jute goods remain at the same level or even decline; (b) accumulation of huge losses and consequently, of huge debts; (c) decline in exports of jute goods; (d) electricity failures; (e) excessive wastage; (f) labor unrest; (g) poor management that affects productivity; and (h) frequent changes in government policies.

The performance of the private sector jute industry is also not encouraging. privatization itself has been a very problematic and slow process. Resistance from workers/employees of the mills and lengthy formalities forced the process to be slow. In 1998, out of forty jute mills in the private sector, three were closed and two lay off. The private sector jute mills run on a very low profile. Up to December 1999, the private sector jute mills have accumulated losses of more than Tk 12 billion.

Use of jute goods as packing materials has many advantages. For example, jute packing make handling of goods easier since jute is flexible, durable and strong; jute sacks can be sewn by hand or machine and hooks can be used without harm to packing; jute packing can be used several times; and goods in jute packing hold well when stacked for long-term storage. Nevertheless, high cost of jute goods compared to synthetics led jute goods users to turn to synthetics. Though synthetic produces affect the environment and they cause health hazards, their manufacturers are smart enough to promote their sales in almost all markets. Recently, people who are conscious about environment and health begun to be appreciative of jute products

Delta Jute Mills Limited: An overview

An organization having a strict & efficient administration is blessing for that organization. DETLA JUTE MILL Limited has also its own administration department, which takes held in managing the function of various departments. The members of the administration department are selected by the governing body & one of the members along take part in the administration section to look after the activities. This department takes care of bank of the employee, their salary level & all other official task due to the decision made by the higher authority for benefit of the organization.

Accounts department

Like every other companies delta has also a separate accounts department. They have a group of highly efficient accounting professionals. They are associated with Abedin & co. chartered accountants to audit their financial statements. Accounts department deals with companies all the accounting information. And provide the information to the decoction makers of the company. Such as

- Maintain all the control accounts

- Manage cost affectivity

- Prepare financial statements

- Contribute on financial report

Purchase/jute department

Purchase department in other word jute department (what thy call) is one of the vital departments. This department deals with the purchasing of the raw materials or raw jute, packets, machines, other infrastructure materials etc. to bring the best output against dealing with imited resources purchase department working so effectively and efficiently through all the years. Especially in the season employees of purchase department elapse a very rusty time.

Export department

Delta Jute Mills Limited is an export based company, so they maintain an export department to achieve the exporting goal. This jute mill exports 100% of its production. In this case to achieve their goal export department also does many

Important activities such as-

- Promoting their products in foreign market,

- Balancing international currency,

- Making export plan

- Forecasting demand

- Determining mission

- Setting time

- Budgeting

- Communication

- Market research

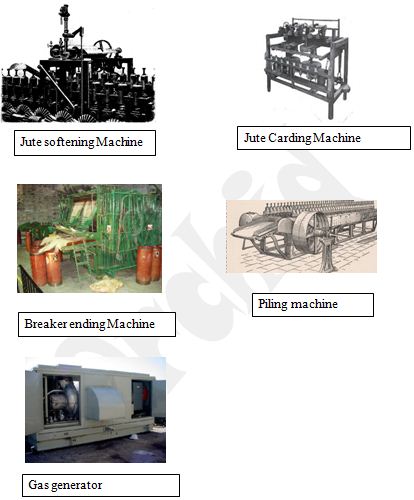

Figure: Machines used in Delta jute mills Limited

Company Analysis on the basis of activities

Delta jute mills limited produces a numbers of products.

Present product:

- Jute bags

- Hessian cloth

- Jute yarn.

MOTIVATIONAL ACTIVITIES

Delta jute mills ltd provides different incentives for the employer as motivational tools. Welfare of the mill staff members and workers is given top most priority and achieve this. The welfare facilities have been made available within the mill. If any employee works for overtime, then he or she will get extra money. Besides these, there are some other facilities like canteen facility, medical facility, credit facility, quarter facility etc.

DEVELOPMENT WORKS

Delta jute mills ltd is a 100% export oriented jute yarn industry. Catering to the need and other end users of jute yarn all over the world. With respect to production the mill is one of the largest in Bangladesh producing about 2000 metric tons yarn annually and intends to raise the capacity very soon.

On the perspective management took dynamic development measure which can be concaved from the following list of development works:-

- Installation of own two gas turbine generator capacities each: 750KV+750KV=1500K produce all the electrical power supply to the whole mill.

- Make: Wood on wooden conical spool.

- Quality: C.B. quality.

- Joints: Manual knots.

- Pacing: Truss.

- It is biggest amount the Bengali one’s mills.

- The area of mill land is 60(sixty) across.

- Producing power to run the mill from 1988.

- Since then no product loss occurred for want of power.

- Construction of single storied staff quarter at a cost of about three million taka.

- Installation of enough godowns to store the jute.

POSITIVE & NEGATIVE ANALYSIS

POSITIVE ANALYSIS

The positive aspects of the company as we found can be pointed out as follows:

QUALITY PRODUCT:

Quality is their touch word which is supreme and final without compromised. They are producing natural fiber product. They are maintaining quality in production.

ELECTRICAL FACILITY:

Two gas turbine generator capacity each 750KV+750KV=1500K produce all the electrical power supply to the whole mill. They use their own product electricity power.

TIME MAINTAIN: They always maintain strict shipment schedule and assume quality. Their activities do not affect the income level of the final consumer. They are very sincere in maintaining export system.

STAFFING FACILITY: The mill is creating jobs for over 1000 people most of them are destitute of the locality. They have single storied buildings for stuffs & employees.

WELL DIRECTION: The mill is run by a team of qualified and highly experienced professionals whose principle objective is customer Satisfaction. So they sincere about that.

EDUCATIONAL FACILITY: Primary and high school for proper education for the children of their entire employer. For that reason employee & employees are satisfied for them.

MEDICAL FACILITY: A fully equipped medical centre with qualified doctors. They hardly belive that, complete mills does not make properly without a medical centre.

ACCOMODATION FACILITY: Fully furnished accommodation facility for married officers and bachelor mess for bachelors. Comfortable accommodation of general workers.

ENVIRONMENT POLLUTION: They are always aware us of environment pollution. They are curious about mills employees so that they arrange essential things for not polluting the factory.

QUARTER FACILITY: They give quarter for their employer. They understand the problem which is generally faced the employers. So they arrange this policy for them to satisfaction.

NEGATIVE ANALYSIS

The negative aspects of this company as we found can be discussed as below:

- LACK OF TRAINING: They don’t arrange any training for their employer. So their workings is getting slow. Employes have no basic idea so that the mills get hampered.

- LACK OF MARKETING DEPARTMENT: They don’t have any marketing department. Because, they are 100% export oriented jute yarn industry. So they don’t need this.

- LACK OF ADVERTISEMENT: They don’t arrange any advertisement program for their products. Because everybody knows their materials.So they don’t need to explore their products.

- LACK OF RESEARCH & DEVELOPMENT DEPARTMENT: They don’t have any research and development department. They know about their product. They experienced about that. There is nothing to researchable.

- LACK OF GROUP INSURENCE: They don’t have any group insurance for their employers and workers. It is so dangerous for employees & employers. It is a bad side of them.

- INSINCERE ABOUT CONSUMERS: They are not sincere of domestic consumers. They don’t arrange any new style for their product. So consumers get bored from them. So they have no interest to buy this product.

Recommendation

There is no industry or organization without limitations. Better organization has less limitations or lacking. Delta Jute Mills Limited has some lacking. Here is a short recommendations are following-

Improvement in Marketing: Marketing is the soul of any business organization which is absent in Delta jute Mills Limited. For this Delta jute mill is facing a lots of problems in market expansion and sells it should provide sufficient marketing approaches to the market. The mill should take up the following marketing approaches-

- They should take the advertising activities to inform the target customer.

- They do not have marketing survey but they should do it to know the demand of the customer and develop the products quality.

- To expand market they should provide an efficient distribution channel.

- They do not have sufficient transportation facilities to the dealers. They should be helpful to distribute the products.

- They should introduce promotional strategy, sale promotion to activate the flow of buying.

- Technological Improvement: Maximum machine in this mill are very old and out dated. It is very tough to do work by it .They should take up all the machineries and technologies for the mill.

- Providing Training Facilities: Delta Jute Mill has no training facilities for workers. Workers learn how to do the work with machine by themselves during their job period. But they should have the facilities to maximize their production by using their proper efficiency.

- Ensure the proper salary: This mill has some facilities for the worker and stuff but they can not get proper salary now –a- days. Sometimes workers do not get any kind of salaries. In that case there creates a clash between workers and authorities. So mill should ensure the worker’s salary and other rights.

- Proper use of the resources and facilities: Delta Jute Mill has many facilities and resources in their own mill area but they can not use these in proper way. They have own produced electric facilities, water supply etc. They should use these facilities in a proper way to increasing their production.

- Conscious about competitor: In the age of competition, they think, there is no competitor of them. But now-a-days it is impossible to reach in a higher position without competition and compete mentality. So they should be aware of the competitor.

- To maintain a higher quality: Delta Jute Mills has lots of potentiality to produce good quality products. But for a wrong maintenance they are getting looser .So they should maintain a quality of their production.

Financial position analyze: According to the financial statement we can find the financial position is not stable of Delta Jute Mills Limited. Their Quick Ratio is .299:1 where as Standard ratio is 1:1.Current ratio, Stock Turn Over, & Gross Profit ratio are respectively .310:1; 19.22 times; & 8.03%. Whereas standard ratios are 2.1; 8times; 20-30%. Stock turn over is more than good enough. To get profit they have to increase their sales volume and decrease their cost of production.