The objective of this report is to analyze the value chain analysis of Benson and Hedges, which is a major brand in British American Tobacco (BAT) portfolio. The purpose of the study is to find out where the value-add and destroy in B&H. Here also focus on identifying overall logistics like raw materials, quality control and to understand Brand awareness measurement procedure activities in Bangladesh. Finally, find out some problems on value chain management process and suggest some recommendation.

Introduction

Research Context

The report titled “The Value Chain Analysis of Benson & Hedges of British American Tobacco Bangladesh (BATB)”. The research is conducted as a part of BBA internship Program 2012, of Department of Marketing, Independent University of Bangladesh. The study has been carried out in BATB under the direct supervision of respective authorities within a 12 weeks internship attachment period.

The aim of this report is to show the value chain analysis of Benson & Hedges, which is a premium segment brand in British American Tobacco (BAT) portfolio. It is the 8th biggest brand in BAT portfolio with worldwide sales of over 15.4 billion sticks per month.

Every firm is a synthesis of activities performed to design, produce, market, deliver and support its product. The value chain model identifies 9 strategically relevant activities that create value for a business. Our discussion will be based on these 9 activities.

Primary Activities cover the sequence of bringing materials into the business, converting them into final products, shipping out final product marketing

Purpose of the study

The purpose of the study is to find out where the value-add and destroy in B&H. I see lots of sector value destroy like inbound logistics B&H raw materials comes from comes outside from the country, as a result, sometimes when demand increases B&H they don’t provide raw material properly here lots of value destroyed. My purpose to find this problem and try to find out the solution. On the other side in operation sector they reuse wastages tobacco it adds lots of value they have a modern machine. In B&H they use FROTOS FOKI machine it is a very high-quality machine. It adds lots of values some time it destroys value my study to find out where this value destroys. In distribution sector how efficient they are how much value they add to find out. Here if any value destroys find out why value destroys here. In marketing sector how they create efficient marketing in B&H. BATB also give proper training their employee how they give training how much value add if here any value destroys to find out. And other supportive activities in value chain how to create value find out.

I also hope to carry out a broad-based and in-depth study that will throw up fresh and interesting perspectives to the issue and try to arrive at and provide logical and practical solutions and recommendations that could definitely help value chain in British American Tobacco.

Statement of the Problem

Business around us is becoming competitive day by day. Innovation is also playing a vital role in shaping up the business around us. Even if we consider our own country Bangladesh has seen the expansion of its middle class, and its consumer industry has also grown. In December 2005, four years after its report on the emerging “BRIC” economies (Brazil, Russia, India, and China), Goldman Sachs named Bangladesh one of the “Next Eleven”, along with Egypt, Indonesia, Vietnam and seven other countries.

Like other industries, the tobacco industry is also experiencing growth over the last years. It has been seen that in Developing countries the number of smokers is higher than the developed countries. The tobacco industry is mainly driven by young population growth and innovative value chain strategy.

This research will find out the important factors affecting value chain strategy B&H and will also investigate BATB performance against its competitors. This research will also expose the expected service level of the most important factors of BATB customers

Research Question.

- To have an understanding of value chain Strategy of BAT Bangladesh.

- to identify relative marketing initiatives taken by BATB and implementation of those activities

- Assessment tools for the value investment of BATB.

- To gain an understanding of the tobacco industry and on the competitive market scenario.

- To understand the different functions of BATB

- To identify B& H inbound logistics like raw materials, quality control.

- To have an Idea how operation work B&H created for BATB.

- To get an idea how outbound logistics actually work B&H in BATB

- To understand Brand awareness measurement procedure

- To develop an understanding and implementing the different marketing strategies and activities of BATB performed all over the country.

Background of the Company:

Nature of the Industry

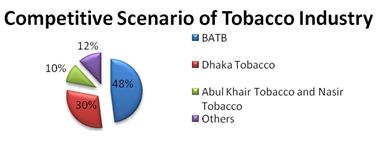

The tobacco industry of Bangladesh is an age-old industry. There a distinct monopoly in this industry where British American Tobacco Bangladesh (BATB) leads the market with more than 50% market share. The other major players are-

The main cigarette manufacturers today are:

- British American Tobacco Bangladesh

- Dhaka Tobacco Industries

- Abul Khair Tobacco

- Nasir Tobacco

- Azizudin Industries and

- New Age Tobacco.

The main biri manufacturers are:

- Akij Biri

- Abul Biri

- Nasir Biri

- Karikar Biri

- Aziz Biri and

- Hundreds of local biri manufacturers.

The industry is very price sensitive in nature. It is also a stick selling market, which means that most of the tobacco consumers normally buy tobacco in sticks, not in packs. These two features-price sensitive and stick selling-influences the business philosophies of the companies.

At the moment, there are two main tobacco industry associations i.e. Bangladesh Cigarette Manufacturers Association (BCMA) and Bangladesh Biri Manufacturers Association (BBMA) representing the industry.

Industry Segmentation:

The tobacco industry can be divided into two markets-Biri market and Cigarette market.

Biri Market:

Biri market is comprised of 72% of the tobacco market. It is basically the non-filter cigarette market with a very two pricing. So Biri is by far the dominating segment in the tobacco industry. A recent trend has shown that Biri market is experiencing decline which is a favorable sign for the cigarette market. BATB does not operate in this market. The major brand in this market is ‘Akiz Biri’, a product of Dhaka Tobacco Industries. This is by far the most popular Biri in the country.

Cigarette Market:

Cigarette market is where BATB has all its focus. The market covers the rest 28% of the industry. But the value of this market is a lot higher than the Biri market. The market can be divided into four segments on the basis of price. They are:

- Premium

- Medium

- Low

- Very Low

BATB operates in the top three segments of the industry. It does not operate in the very low segment. Along with BATB, DTI and Alpha Tobacco is also a major player in the low segment.

Today, the market is estimated to be 64.2 billion sticks of Biri and 51.8 billion sticks of machine manufactured cigarettes. Biri overtook cigarettes as the more popular smoked product in 1979. However, the market for Biri has been on a declining volume trend since 2003. This reflects the switch by consumers due to social pressure, urbanization, literacy rate, economic growth and awareness by consumers. The market has a high International Brand share (18.2%).

Competitive Scenarios in the Cigarette Market:

In May 2008, Philip Morris International launched both full flavored and light variants of Marlboro brand cigarettes in different markets of Dhaka. Dhaka Tobacco Industries is manufacturing and distributing the brand.

BAT Bangladesh and Dhaka Tobacco Industries together hold more than 80% of the cigarette market share.

Tobacco products are distributed either by manufacturers themselves, third-party distributors or wholesalers. The sales and distribution effort requires a large number of field employees and agents because they have to serve about 880,000 individual retail outlets throughout Bangladesh with a growth of 10% per annum.

The number of retail outlets is estimated to be growing by about 8% a year. The proliferation of retail outlets is mainly due to the ease of entry and the low capital requirement. Many of these outlets operate on limited capital and are unable to purchase quantities beyond their immediate daily sales. The high number of retail outlets has created a “stick market” and consequently imposed more frequent sales visits compared to other similar businesses.

The competition in the cigarette market is based on the price segment. There are individual competitive brands in each price segment. There was no competition in the premium and a medium segment where the top International Brands of BATB dominate the market. But when Dhaka Tobacco Industry (DTI) launched the brand Marlboro and Thames in the both Premium and Middle segment the competition is raised. But still in the Segment of premium and Medium BATB is the leader still. Only in the low segment, there is a competition where mainly three companies have their individual stakes and trying to take the segment leadership. In the very low segment, there is also competition among brands like Sun Moon, Five Star, Wilson, Gold Hill etc

| Segments | Brand | Company |

| Premium | B&H, switch, State Express 555, Mal | BATB DTI |

| Medium | JPGL, Pall-mall, Capstan Filter Kings Thames | BATB DTI |

| Low | Star Filter King, Scissors Filter King, Navy, Summon Filter King Senor Gold Marine | BATB DTI Alpha Tobacco Abul Khayer Tobacco |

| Very Low | Pilot, Bristol, Hollywood Five Star, Rally, Sheikh, Maris Wilson Gold hill | BATB DTI Azzizuddin Tobacco |

Table: The Competition of Cigarette Industry of Bangladesh in Different price segment

Primary activities

Inbound logistics Benson &Hedges

Inbound logistics is an integral element of business operations for a manufacturing firm, involving the processes of receiving, storing and distributing raw materials for use in production. It is the first stage in the value chain, which business management expert Michael Porter outlined in his 1985 book “Competitive Advantage.

Every single raw material of Benson & Hedges is imported. The procurement department imports these as required and sends them directly to the factory warehouse with the help of inbound logistics. As these raw materials are ordered in bulk, economies of scale are achieved which in turn adds value to the product.

Raw materials cigarette

| Tobacco | Imported (Brazil, USA) |

| Cigarette paper | Imported |

| Seam glue | Imported |

| Tiffin paper | Imported |

| Tiffin glue | Imported |

| Filter paper | Imported |

| Plasticizer | Imported |

| Ink | Imported |

Raw materials of cigarette packet (B&H)

| Blank | Imported |

| Inner frame | Imported |

| Foil | Imported |

| Glue | Imported |

| Cello penne paper | Imported |

| Easy opening device(EOD) | Imported |

| Tear of ribbon | Imported |

| Tax stamp | Imported |

| Outer Bopp | Imported |

| Colour | Imported |

- Here all the raw materials bring outside from the country so that B&H raw materials are better than other cigarettes here adds lots value.

- On the other hand here some time value destroys because sometimes this raw material not finding It is a big problem.

Operation Benson &Hedges

Operation: operation means converting materials into final products. When converting final product added lots of value.

The Primary Manufacturing Department:

The primary manufacturing department (PMD) is responsible for further conditioning the important tobacco to make it ready for production. The tobacco passes through a set of integrated and regulated machinery whose purpose is to blend the different ‘packing grades’ in specified proportions, convert the bales into ‘rag’ suitable for use in cigarettes, and bring tobacco to a uniform temperature and moisture.

The Secondary Manufacturing Department:

The secondary manufacturing department (SMD) uses the tobacco that is blended and conditioned by the PMD along with wrapping materials to manufacture cigarettes. The PMD delivers its final processed tobacco to Cut Tobacco Store (CTS). The CTS has a 50-ton storage capacity and the tobacco is stored there typically for one and a half days before it is used. The SMD brings in the processed tobacco from the CTS as needed for production along with wrapping material. Currently, there are 16 cigarette-making machines at Dhaka factory, which are operated in three daily shifts. Shift engineers and officer’s monitor shift activities to ensure quality production. The flow of tobacco and cigarette paper to the cigarette making machines are regulated by six (programmable Logic Controlled) PLC controlled feeders. These feeders send in the required quantities at the right time to ensure smooth production.

Each of cigarette is monitored by a separate feeder. In addition to the tobacco and cigarette wrapping material, filter rods are fed into the machines for cigarette production. The machines combine these three inputs to generate cigarettes as output. Defective cigarettes are either identified manual or by built-in sensors and removed from the production flow.

The tobacco from these wastes is removed and reused for cigarette production. This is added great value from BATB.

The manufactured cigarettes are deposited in trolleys and carted to the packing machines. There are currently 18 packing machines at Dhaka factory. These machines are equipped with the wrapping material used to pack the cigarettes. Almost all of the wrapping materials used are imported. Local companies, however, conduct the printing work that is required. The manufactured cigarettes are fed from trolleys into the packing machines, which generate the packed cigarette as output. The flow is monitored closely to identify and eliminate defective products. In addition to the cigarette manufacturing and packing machines, Dhaka factory has two Secondary Production Units (SPU). These are used exclusively to produce the State Express 555 and John Player Gold Leaf brands. These modern production lines are different from the other machinery in that both cigarette manufacturing and cigarette packing can be conducted in one process flow. This reduces the time needed to manually put the cigarettes into trolleys and cart them to the packing machinery. The SPU makes approximately 8000 cigarettes per minute. Defective cigarettes are detected by sensors in the machines and are removed automatically. In addition, manual checking is conducted for quality control purpose.

In Benson &Hedges, a very special machine called “Protos Focki” is used to produce the cigarettes of the BAT. This is an automatic machine capable of producing 10,000 sticks of cigarette per minute. It takes almost one and a half year to build a Protos Focki and it costs $4,000,000.

Raw materials are placed at designated points in the machine. The operator inputs the required quantity and the machine automatically uses the resources to produce the desired quantity of output. The outputs are finished goods and are ready for sale. Each packet of Benson & Hedges contains 20 sticks. These sticks are wrapped in a golden wrapper which helps keep the cigarettes still. Then it is put in the final gold packet. This packet has a hinged lid for easy use. There is also a film coating on the pack which helps reduce damp on a cigarette. This is the most advanced cigarette manufacturing machine that is exclusively built for BAT and is not available anywhere else. This huge initial investment, in turn, reduces the cost of production and adds value to the final product.

Advantage: Protos Foki maintains product quality very high. it makes 500 B&H packets per minute. Its packet quality is very high. It has another big advantage that is if rapper close packer is not close it is the very big advantage. In another machine like GLD rapper close all packer close so production. It has another big advantage they said if any B&H quality comes bad it automatically display in the monitor. So this machine added lots of value.

Packaging: For many years, B&H cigarette packs were hard or soft, but otherwise changed very little. In recent times, consumers have become increasingly interested in packaging improvements, and these can be a strong source of competitive advantage. BATB is meeting consumer interest with a stream of packaging innovations, such as compact packs, side-opening packs, packs that open like wallets, waterproof packs, re-sealable packs to keep the contents fresher and packs with rounded edges.

Innovations vary across its brands, brand variants and markets and its approach enable BATB to adapt its offers flexibly to local preferences. BATB’s guiding focus in innovations is of relevance to the consumer, speed to market and being continuously ready to improve.

Outbound Logistics Benson &Hedges

The movement of material associated with storing, transporting, and distributing goods to its customers.

British American Tobacco Bangladesh (BATB) extends all across Bangladesh. They have their head office and factory located in Dhaka. There are three leaf regional offices located in Bandarban, Kushtia, and Rangpur. They have six regional marketing offices all over Bangladesh.

The six metro markets are Dhaka, Khulna, Mymensingh, Bogra, Sylhet, and Chittagong. Distribution is done with the help of authorized dealers. BAT does not take their products directly to the market. There are 52 authorized distributors that distribute the products to 510,000 outlets approximately.

Distribution is divided into three categories. They are: Retail Store, Retail Cash and Carry, and Bazaar Cash and Carry. The distributors use their own vehicles, covered vans, cycle vans, etc to distribute the product. And in the passive outlets, the areas are very close to the river, where vehicles cannot go, they supply the product through the boat.

The channel of Distribution:

Regional Go-down: There are five regional go-down throughout the country to fill every regional demand just at the time of need, and to overcome various uncertainties related to the physical distribution of products, every regional go-down is directly controlled by separate Regional Manager to face the regional physical distribution challenge.

- So this five regional go-down adds lots of value.

Carrying Contractor: They are the party engaged in the physical movement of cigarettes from head office go-down to regional office go-down. Normally they are the truck owners who take all the risk and responsibilities of physical movement of goods between two warehouses.

- Sometimes this truck owner destroys value to damaged goods.

Distribution Warehouse: All distributors have their own warehouse, where cigarette can be kept safe while not degrading its product quality. Distributors buy the cigarette from BATB and from that point ownership and all responsibilities of the products go to the distributors.

Internal Carrying Agent: They are like carrying agent but carry the small volume of products. Normally they are local truck owners. They carry products from, regional godowns to distributor warehouses. They also take all the responsibilities and risk engaged in the physical movement of products.

- So here some time destroy lots of value.

Opening Stock at Distributors’ Office: Apart from the warehouse, every distributor also maintains another stock at their office. This stock is for maintaining any change in market demand instantly. Dealers sometimes sell cigarette through their counters to face the special situation.

- Here adds lots of value because here maintain another stock office.

Delivery Van: All the delivery vans are owned by the dealers to assure the supply of cigarette on the door of wholesalers, cash & carries and retailers just according to their demand. There are two types of delivery vans. One is Scooter van and another is Rickshaw van.

Cash & Carry: They are businessmen who sell cigarette directly to consumers and at the same time they sell cigarette to the retailers.

- Here adds lots of value because sell directly to consumer and also retailers

Retailers: Retailers are at the end of the physical distribution system of cigarette selling products directly to the consumer.

The distribution chain shows how the product goes from the factory to the hands of the consumers. It all starts with the factory where the tobacco is turned into the cigarette and packaged. The cigarette comes out of the factory as a finished good and is kept in the company’s warehouse. Then the tobacco product goes to 6 regional depots. From the depots, the authorized distributors take it to their distribution warehouse. Then from the distribution warehouse, the distributors use their own vehicles to get it to the market.

BAT ensures that no value is destroyed throughout the distribution process.

Limitation: In distribution, there is the little limitation. Some time truck, not the proper time to reach their destination. Another big problem is that this truck material is very costly probably B&H 1 truck carry 3 crore taka. So they do not send their truck at night. It is a big problem.

Departmental Overview (Sales &Marketing)

British American Tobacco:

Marketing:

Successful marketing is the bedrock of growth for any fast moving consumer goods (FMCG) business and we are no exception -Jean-Marc Lévy, Marketing Director

This is how British American Tobacco sees the Marketing activities for its success and prosperity.

But when it talks about growth, there’s a big point to make clear. By growth, it doesn’t mean ‘selling smoking’ to boost the number of people in the world who smoke or the amount they smoke. It means growing its share – more specifically, the value of its share – of the large number of adults who choose to be tobacco consumers.

BAT has a mature market – one where everyone already knows what tobacco is. There would be no commercial sense in trying to promote tobacco products to people who know what they are and have decided they don’t want them.

BAT invests in positioning its high-quality brands competitively for the adults who’ve decided they do want to buy tobacco. And it has shown that through focus, intelligence, responsiveness and a high priority on responsibility, it can successfully build the brand loyalty of adults who have chosen to be tobacco consumers and win consumers away from competitor brands.

A billion adults worldwide choose to consume tobacco. Its aim is not just to maximize its share of sales – value and quality are high on its agenda. BAT aims to keep adding value to its consumers, trade customers and shareholders through an approach it calls ‘win-win-win’. This means giving BAT’s consumers premium value through premium quality and unique, differentiated brands, enabling its trade customers to benefit from premium margins and, by satisfying both consumers and trade customers, delivering long-term sustainable value for the shareholders.

BAT estimates that sales by our subsidiary companies account for 13 percent of the global cigarette market.(In 2010)

Approaches to Marketing:

BAT’s business is about offering adult consumers high-quality brands that they will choose over competitors’ products. It is not about boosting the number of smokers, increasing the amount they smoke or targeting the underage.

BAT’s International Marketing Standards, revised in 2007, detail its commitment to marketing appropriately and only to adult consumers. The Standards apply to all its companies globally and govern its tobacco marketing across all areas including print, billboards, electronic media, promotional events, and sponsorship.

BAT’s updated Standards were rolled out during a 12 month period and all its companies were expected to confirm their adherence to them by 30 June of the next fiscal year.

To track implementation, a self-assessment audit of adherence was conducted by all Group companies shortly after the deadline. The assessment reports an overall adherence rate of 97 percent but it also identifies some areas where it is not yet meeting its updated Standards.

Instances of non-adherence are principally related to inconsistencies in interpretation of the Standards at a local level. The self-assessment highlights the need for clarification of this interpretation around certain promotional activities and for sanctions that may be applied to retailers who sell to the underage.

BAT has issued additional guidance to its companies to help address these issues.

Action plans are now in place to help it achieve 100 percent adherence by the end of 2010. Progress against these plans will be monitored through the Regional Audit and CSR Committees and the Board CSR Committee.

What BAT does not do in Marketing:

Strict laws in many countries and its voluntary International Marketing Standards mean there are many things it doesn’t do in marketing.

Top of the list is that it doesn’t market to the under-age. It doesn’t do ‘product placement’ in films, plays or TV programs, or link BAT’s product brands to celebrities or to sporting, professional, social or sexual success. Its entire consumer packaging carries a clearly visible health warning, even where the law doesn’t require it.

What BAT does for its Success:

Given the restrictions – including the tight restrictions BAT set for itself – people often ask how it delivers such strong brand growth?

The answer is simple, though it takes hard work and skill to achieve. BAT has developed approaches that it believes are appropriate for modern marketing of its challenging product, and pursue excellence in everything it does.

The Structure of the Marketing Department of BATB:

Marketing is “The Department” of BATB. The marketing department has recently been rebuilt by merging Brand marketing and Trade marketing. Earlier these two were individual departments. But now with the “Power of One” theme the brand and trade department has formed a very efficient marketing department.

While the Brand Marketing wing focuses on the branding aspects of a product, the Trade Marketing & Distribution (TM&D) Wing focuses on the trade and distribution aspect. These two wings are joined by the Trade Development Team (TDT).

Brand Marketing:

The Brand Marketing department concentrates on satisfying consumers’ needs from within the brand portfolio. Once consumers’ needs are understood and evaluated, brands can be made available, accessible and desirable through strong, consistent communication. The brand marketing elements cover the adopting of products, logistics and brand marketing policies that best meet the needs of particular trade channels and strategic customers. The Brand Managers and Brand Executives are responsible for the allocated brand(s). They are responsible for all type of brand management activities.

Market intelligence includes the market research team. The team keeps the constant eye on the market situation. Through continuous research, market research teams generate useful market information for the brand managers. The interface is required between brand marketing and research which is carried out by any project that is divided into three phases:

- Preparation prior to the study

- Collection and analysis of data

- Presentation and utilization of information

There are different sort of researches carried out at the field level for gaining important information.

Support Activities (B&H)

Firm’s Infrastructure: The infrastructure of the company has a broader field where the company plays its important role. BATB has 6 Regional Trade Marketing Offices (RTMOs), 12 Regional Sales Depots, 1 Factory, 1 Green Leaf Threshing Plant, 7 Leaf Depots and a Head office consisting of Corporate Head office and Production Head office. The Company’s Head office and Cigarette factory are located in Dhaka. A Green Leaf Threshing (GLT) Plant has been set up in Kushtia and it has started operation from April 1995.The company’s products are manufactured in the factory at Mohakhali, Dhaka. The Plant Manager who reports to the Production Director at the Head Office heads Dhaka factory. The company’ procures tobacco leaf maintaining the international standard and it imports processed tobacco leaf for its international brands. It procures green tobacco from the registered farmers of the leaf area mainly for its local brands. The company’s authorized leaf areas are located in Kushtia, Chittagong, and Manikgonj. But the bulk of tobacco leafs comes from Kushtia region. The Chittagong area is under development process and it now covers Rangunia and Lama. The company operates 7 leaf depots in the leaf area. 4 of them are located in Kushtia region, 2 of them are located in CDA and other 1 is in Manikgonj, The company provides all sorts of support to the registered growers through its depot personnel. This includes technical know-how, agricultural inputs, and financial assistance. The company performs its sales and distribution operation all over the country through its five regional sales offices. They are located in Dhaka, Khulna, Chittagong, Shylet, and Rajshahi. Each of the regions is again divided into operational areas, each of which in turn is divided into territories. To perform its sales and distribution smoothly, the company operates 10 sales depots in different locations of the country and it has 63 authorized departments.

Firm’s Infrastructure also covers the cost of general management, planning, finance, accounting, legal and government affairs. BAT does not disclose their profit margin but according to their last annual report, They have made a profit of Tk. 1.79 Billion for the period of January – September 2011. Part of this profit is used to finance the firm’s activities. This firms infrastructure create lots of value in BATB.

Human Resource Management:

BAT has been a pioneer in recruiting and creating the best managers in Bangladesh. They choose the best and most talented graduates each year to ensure that they have the best and most effective workforce.

The employees of the BATB are dynamic, self-motivated and energetic to perform any assigned job because they are selected on the basis of excellent academic and experience.

The company employs 1,244 permanent employees and the varying number of seasonal a temporary workers as required. Each permanent employee receives remuneration in excess of Tk. 36,000 per annum. Remuneration depends on the nature and conditions of work. The workers are labeled in the following categories:

- Permanent

- Probationer

- Temporary (seasonal)

- Badli

The casual Trade union is established in the following company’s working locations:

- Office and Dhaka factory

- Kushtia Head leaf factory

There is a positive relationship between the company and the trade union based on mutual trust and respect. All the employees of the company belong to the trade union. When a worker becomes a member of the union, according to his request a certain amount of his wage is deducted from the union subscription fees on a check-off system. Trade union election is held after every two years and governed by their respective constitutions. The terms and conditions of services of the employee are negotiated and determine through a process of collective bargaining between the company and the union

Head of Human Resource is the head of the department. The Human Resource Development Manager, Production HR Manager, and Resourcing and Remuneration Manager work under him.

The HR process is carried out through four ‘Guiding Principles’.

- Open-mindedness

- Strength of diversity

- Enterprise spirit

- Freedom through responsibility

Here this all principals create lots of value in BATB this all is very important

Technology Development:

Information Technology department was mainly acting as a supporting service for all the other functions of the BAT. As the emergence of super information highway another technological advancement made the business world more competitive, BAT also made necessary adjustments towards the changes and in continuation, with that process, IT was made a separate department in February 2000. The head of IT is also a member of the executive committee and he is supported by the function support IT managers.

As stated earlier, BAT uses a state of the art technology Protos Focki which has a capacity of producing 10000 sticks per minute. This is the most efficient cigarette manufacturing machine till date.

This modern machine creates lots of value and it also minimizes cost in B&H. And also minimize wastage.

Procurement: BATB follows strict measures to maintain quality parameters. Any type of product is quarantined whenever any dissimilarity in these parameters is detected. Every single raw material used for Benson & Hedges are imported. Benson & Hedges uses 100% Virginia tobacco which is a world-class blend. The tobacco is imported from Brazil, Argentina, Mexico and West Indies. The white cigarette paper is a special type of paper which is imported from Malaysia. The filter comes from Japan. The glue, used for wrapping the cigarette paper, is imported from Spain. The ink, used for printing on the cigarette paper, is imported from France. There is also a golden wrapper inside the packet which helps keep the cigarette still. This wrapper is also imported from France. Finally, the authorized gold pack is imported from Turkey.

Core Business Processes:

The New Offering Realization Process: New offerings are by BAT Globe house and is executed accordingly throughout the globe.

The Market Sensing Process & The Customer Acquisition Process & Customer Relationship Management Process: These processes are performed by the same department using state of the art consumer engagement programs. Benson & Hedges is associated with music and lifestyle. They organize several programs to create filtered customer database. These are the customer group to which products are marketed using permission marketing. Their feedbacks are channeled back into BAT.

The Fulfillment Management Process: This task is performed by the management team of the BAT.

Methodology

Research Design

The research is conducted for finding out how Value Chain Analysis of Benson & Hedges of BATB is maintained, what things are considered and the tools used for this purpose. As BATB is an International Company and it has passed its 100 years of glorious journey, it has already had a structured Value Chain in action. My task is to find out the value and presents it in this report in a structured way. As the task is discussing the procedure and the contents are pre-structured the research will be a DESCRIPTIVE RESEARCH METHOD.

The methodology includes literature review, secondary data analysis, interviews with the responsible person.

Literature Review and Secondary Data Analysis: The literature searching, secondary data analysis and the case study are the sources of the describing value chain strategy and the trade marketing activities and the Integrated Marketing communication for enduring brands. The literature search is concluded from the synopsis of the case studies conducted by BATB earlier. The secondary data are taken by a website of British American Tobacco, the newspaper article on BATB.

Primary Data: In the report, primary data has been collected through interviews and contacts with BATB personality. Interviews have been administrated by formal and informal discussion. No structured questionnaire used. Information regarding office activates of the BATB are collected through consulting BATB records and discussion with BATB personal.

Qualitative Research, Surveys, and Observations: A qualitative study will be conducted to understand the relevant issues following certain surveys of experts (knowledgeable persons), focus groups and in-depth interviews. This is done for understanding the inbound logistics, operation, outbound logistics, sales& marketing, other supportive activities, followed by a descriptive study based on primary data using surveys and observations. The study will cover a number of bases to conduct depth interviews and focus group discussion.

Nature of Research

The present study will find out the likely factors that influence Value Chain Analysis of Benson & Hedges. To find out the most important factors, this study will perform a Descriptive research.

Research Timeline

| 2012 | February 1 | Research proposal writing and literature review |

| 2012 | February 15 | Data collection procedure |

| 2012 | March 15 | Data Analysis and interpretation of findings |

| 2012 | April 22 | Submission of the Draft copy of the report |

| 2012 | April 29 | Submission of the final copy of the report |

The Research Modality:

In conducting qualitative research Certain Surveys of experts, Focus group and in-depth interviews will be conducted. If we Frame the research it will be

| In-depth Interview | Unstructured | The Discussion for having an insight on How the value chain is built up, what things to be considered, how the value implemented. |

| Focus Group Discussion | Unstructured | How the value chain is made up, what things to be considered, the maintenance procedure |

| Observation | Unstructured | Ware House, PMD, SMD, and Different Point of sale location. |

| Consumer Observation | structured | Matching up the Defined Brand Personality in purchasing point and consuming point.

|

| Secondary Data Analysis | Structured | The theory of inbound logistic, operation, outbound logistic, sales &marketing, service and other support activities |

Table: The research concept

In-depth Interview:

| Designation | Sample size | Duration | Topic |

| Value chain British American tobacco in B&H | 1 | 30 minutes | What is the value Chain strategy of B&H, how they are being implemented, What factors are considered, controlling measurement. |

| Research Team Executive | 1 | 30 minutes | How the database is managed, what type of data are being stored, procedure of collecting data, the analyzing method |

| Trade Marketing Executive | 1 | 30 minutes | The procedure for measuring up marketing investments and the necessary measurements tools |

| Line Manager | 1 | 30 minutes | The overall value chain like inbound logistics, operation, outbound logistics |

Focus Group interview

| Designation | Sample Size | Duration | Topic |

| The inbound logistics, operation, outbound logistics, sales & marketing, service | 3 | 30 minutes | How the value chain is made up, what things to be considered, the maintenance procedure |

Secondary Data analysis sources:

| Topic | Source |

| value and value chain related theory | Books, Literature Reviews, Article, Website |

| Marketing and Marketing Related theory and practices | Books, Literature Reviews, Article, Website

|

| Organizational Background and Industry of BATB and BAT | Web Site of BAT and BATB

|

| Case Studies on BATB | Website, Internal Database of BATB |

Data Findings and Analysis

Question No. 1: Was an open-ended question, letting worker freely express how their view about Protos Focki machine. The researcher has come across the following facts:

- Protos Foki maintains product quality very high. It makes 500 B&H packets per minute. its packet quality is very high. It has another big advantage that is if rapper close packer is not close it is the very big advantage. In another machine like GLD rapper close all packer close so production. It has another big advantage they said if any B&H quality comes bad it automatically displays in the monitor.

- Protos Foki has some disadvantage they said. Some time it missing blank. If one cigarette quality fails all cigarette dump. If some material goes rough all parts of machine jam with a minute. Another big problem if one rejection all are rejected so that waste lots of cigarette. Some time missing inner frame and some time goes cigarette van empty.

Most of the operator said if company modify two things this machine they comfort to work.

a) Cigarette brand hopper modify.

b) Stamp unit modify

At last all of this problem the entire operator said they are very satisfies to work Protos Foki.

Discussions and Recommendations

After analyzing the study in the context of, the following issues were found to be Recommended that BATB value chain strategy in B&H is very nice. They maintain their strategy properly. In lots of sectors, they add lots of value. Inbound logistics every raw material they bring from the outside. In operation sector, they use Protos Foki machine in B&H. Their outbound logistics system is very nice. They distribute their product very efficiently. BATB service and training system also very nice. Their employee is very happy their company. Their marketing system is very innovative in other tobacco industry. They use modern HR system. Every officer, employee, worker are very proud to work for this company. So their value chain system in B&H is very nice.

Conclusion

BAT has ensured value addition at every stage of the supply chain. The BAT must further focus on price, quality, and performance of their product lines and brands to stay competitive in the industry. Although people are becoming more aware of the health hazards of smoking, customers who smoke on a regular basis face tremendous difficulty in giving it up. Moreover, the increasing activities of anti-smoking lobbyists will not have much effect on the regular smokers. Still, BAT should contribute extensively to research and development for a better variety of tobacco leaves that will be less injurious for health and more cost-effective for the customers. On account of advancement in microbiology, BAT should involve scientists more frequently to come up with a variety that eliminates the harmful qualities of tobacco and only the useful qualities are available for consumption. This can trigger a complete revolution and can be sold as some product of great herbal value.