Introduction

As the world is becoming more aware of Mother Nature’s declining resources, the need for green and sustainable alternatives to preserve the natural resources is also increasing. Many industries today offer ‘green’ products, and one such industry that is on the rise is the ‘tree-free paper’ industry.

The pulp and paper industry is the largest industrial wood consumer in the world. Although recycling has helped, it has not been able to make an appreciable difference. Using agricultural residues as a fibre source for paper offers clear environmental benefits, making use of an existing waste product while displacing the need for virgin fibre. Farmers also avoid generating the air pollution that results from the widespread alternative practice of burning the residues in the field.

Tree-free papers offer an environmentally preferable alternative to tree-based papers for several reasons. The plant sources of tree-free fibres re-grow rapidly and the harvesting of the plants does not disrupt natural ecosystems. Additionally, the processing of tree-free fibres to produce pulp for paper-making requires considerably less energy and chemical input than does the processing of wood-based fibres. With growing restrictions on timber harvesting, and increasing concerns to preserve forests and reduce pollution from virgin wood pulp production, tree-free papers are gaining increased attention.

Paper Industry: Local and Global Environment

Current World Scenario

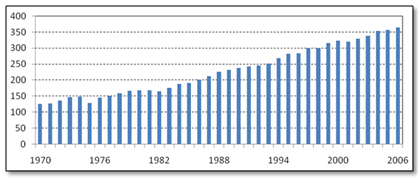

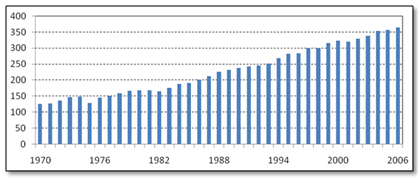

As Figure 1 shows, the global production of paper and board increased—with two exceptions (1975 and 1982)—continuously over the last few decades from 125 million tons in 1970 to 365 million tons in 2006.

Fig 1: Global Production of Paper and Paperboard (in millions of tons)

Source: FAO-STAT Forestry Database (http://www.fao.org/corp/statistics/en/)

It is projected that the market for paper and paper board will continue to grow globally at 2.3 percent per year until 2030, with particularly sharp increases in developing countries (due to increases in population, literacy rates, and quality of life) and a slight decline in the most advanced industrialize counties (due to advances in electronic communications).

The continued growth in paper consumption as well as the emergence of bio-fuel will lead to an increased demand for wood; creating additional pressure on the world’s diminishing forest resources. Some efforts at the national and international levels are ongoing to find suitable substitutes for wood fibres, which are commonly called non-woods. Some of these non-woods are already used for papermaking, accounting for about 10 percent of the world’s pulp production. Most non-wood pulp is produced from wheat straw in China and India. These two countries account for about 80 percent of the total non-wood pulp production. 3 Over the last three decades, the share of non-woods for papermaking has increased considerably in India.4 Other non-wood fibres have been identified and used, but have not reached yet efficient industrial production levels.

Overview of Paper Industry in Bangladesh

Production

The paper industry in Bangladesh went into operation during late 1950s when Daud Group had established the Karnaphuli Paper Mill (KPM) at Chandragona in Chittagong using local bamboo as raw materials. Following that, Bangladesh’s private sector paper mills started with the setting up of Khan Md Iqbal Board Mill in early 1980s in Narayanganj.

Currently, 55 local private paper mills account for a market share worth Tk 25 billion by producing more than 550,000 tonnes of paper a year.

Consumption

As Figure 2 shows, Bangladesh’s consumption of paper and paperboard has been slightly more volatile than consumption at the global level shown in Figure 1, but still shows a clearly increasing trend.

Fig 2: Consumption of Paper and Paperboard in Bangladesh (in thousands of tons)

Source: FAO-STAT Forestry Database (http://www.fao.org/corp/statistics/en/)

|

In Bangladesh, the paper industry uses mostly bamboo and mixed hardwood. Both of these raw materials come from Bangladesh’s forests, which is however not sufficient to satisfy the demand for paper in Bangladesh. Hence, beginning in the mid-1980s, Bangladesh has imported increasing amounts of pulp and paper. Today, Bangladesh imports about 250 thousand tons of paper and paperboard a year, which amounts to about US$300 million.

With increasing imports, the domestic production of paper and paperboard has decreased drastically in Bangladesh. Today, Bangladesh produces less than 20 percent of its paper and paperboard consumption. As documented by FAO (2002), Bangladesh’s capacity to produce paper and paperboard has remained constant at 121,000 tons during 1997-2001, which implies that Bangladesh’s paper mills are producing paper and paperboard at only half of their capacities. Though Bangladesh continues to export some paper and paperboard, the current amounts exported are very small, about 100 tons a year. In practical terms, the export of paper and paperboard from Bangladesh has ceased in 1992.

These developments are mostly due to the increasing shortages of wood fibre in Bangladesh, though they are also influenced by falling paper prices at the global level, due to an oversupply of paper and paperboard that built up at the global level mostly during the 1990s.

Our Business – EcoPaper

We are going to produce shopping/carrier bags, food packages, newsprint and writing paper made out of tree-free or non-wood paper, as substitute of polyethylene [Plastic], Styrofoam or wood-pulp paper made bags or packages.

We will use four different fibre sources as our raw materials:

- Agricultural Residues: Sugar cane husk (bagasse); Cereal straws

- Fiber Crops (On-Purpose Cropping): Hemp, Kenaf, Jute, Flax

- Textile and Cordage Wastes: Cotton linters, cotton and linen scraps, old rope

- Wild Plants: Wild grasses, Sisal, Bamboo

Why Tree-Free? [Business Justification]

Bangladesh is facing an acute shortage of fibrous raw materials for the production of pulp and paper. On the other hand, the demand for paper and paper products is increasing day by day. So there is a huge opportunity for paper and paper product manufacturers to create a market for environmentally safe paper especially for other environment-conscious business clients.

Abundance of resources

Bangladesh has a huge amount of unused jute fibre, which is highly suitable for papermaking in Bangladesh, and is one of the main components of fiber crops for our business.

Agricultural wastes like rice straw, dhaincha, golpata fronds, cotton stalks, corn stalks, and kash are also available and may be used forpulp production. Given the different properties of these different non-wood fibres, jute pulp can be used as a reinforcing agent with other non-wood pulps for the production of high quality paper in Bangladesh.

Bangladesh also has an abundance of textile and cordage wastage from the Ready-Made Sector in Bangladesh, which is one of the largest industrial sectors in the country.

Saving the Nature

As the demand for paper rises in many developing countries, so does the amount of deforestation. The use of wood-pulp, still the preferred raw material for paper making, is a threat to the ecological environment. The goal is to support production of papers that reduce demand on forests, incorporate pulp from sustainably grown crops (which may include trees), and dramatically reduce waste by using materials that were formerly thrown away: recyclable paper and agricultural residues.

Tree free paper also has less CO2 emission and the whole production process is free of harmful by-products that may prove to be a problem for the environment.

Less Landfill

Landfill and incinerators are a problem because they trash resources. Printing and writing paper dumped into a landfill could have been recycled up to a dozen more times, saving trees, water and energy and reducing pollution each time. Incinerators are even more wasteful than landfills, even though many are touted as energy-producers.

Tree-free Eco paper will be conserving primary resources such as trees to prevent such resource opportunity lost to landfills and incinerators.

Incipient Demand

Although there is an existing demand for paper and paper products, demand for tree-free products is still not that imminent. However, there is scope for an incipient demand, where we have to create the demand for not only paper but environmentally safe paper products. There is a huge market for paper products, since most of the leading paper manufacturers are now expanding their plants aggressively; we believe that our products will also be well accepted.

Vision

Our vision is: “To save the environment by reducing deforestation to produce paper products and also to make the paper-packaging industry self-dependant by eliminating the need for imported raw materials.”

Mission

Our mission is: “Save the environment by saving the trees”

Goals

Our primary goals encompasses of these major objectives:

I. Protecting the environment and keeping it green, reducing land-fill needs and carbon emissions

II. Making the paper industry domestically self-sufficient

III. Making quality paper and paper products for the domestic market and eventually for the global arena

IV. To maintain healthy relationships with all our value chain members

Target Customers

We would be focusing on two segments of customers:

Business Buyers:

- Food shops that need one-time-use food packages (box/glass/plate/serving tray)

- Branded apparel or other store that use good-quality paper bags with their own logo

- Any company that is enthusiastic about green marketing or can be drawn to green marketing

- Newspaper Industry

Individual Customers:

- Customers with green preference lifestyle, who is:

- Concerned about indoor pollution

- Aware of environmental degeneration

- Eager to support green movement

- A green consumer

- Willing to pay for quality over low price

Competitive Advantages

Although this section will be discussed in further details later on in the report, we would nevertheless want to summarize it into these points:

- This business of producing tree-free paper food packages is one of a kind in Bangladesh, so we will enjoy the first-mover advantage if we can be successful at achieving our desired production levels

- Eco-friendly paper is an unexplored area, and with the rising concern about environment all over the world, and so this kind of product will appeal to the environmentally conscious people enhance the image of the companies who will use this product.

- Our technology is also new and hence in that arena we will have a competitive advantage as well.

- Other paper manufacturing companies depend on imported wood-pulp, while EcoPaper relies on domestically available non-wooden raw materials.

Legal Issues

Any business firm or manufacturer in Bangladesh or any other nation in the world has to comply with specific legal issues that are particular to that country, and also comply with legal issues that are international requirements in the growing age of globalization. Here we outline all the important legal issues we have deal with once we start our business.

The Company and Ownership

We are a private limited company and a manufacturing firm. Our company is restricted in its rights to transfer its shares and it is also limited in the number of its members. The three of us have equal ownership of the business, and hence have equal decision-making power.

Starting the Company

In order to begin the full operation of this company, we would need to take a number of legal issues into consideration. These are discussed as follows:

Registering

- Register the proposed name of the company with the Register of Joint Stock Company online and get a name clearance certificate from by the Deputy Registrar, RJSC.

- Pay for adhesive stamp fees to BRAC Bank (our designated bank account)

- File memorandum and articles of association with the Registrar of Joint Stock Companies and Firms for registration

- Make a company seal

- Register with the tax authority, under the National Board of Revenue (NBR) and procure a tax identification number for the new company.

- Register for VAT

- Obtain a trade license from the City Corporation, including:

-a certified copy of the company’s articles and memorandum of association

-a copy of the certificate of incorporation

-the company’s statement of bank solvency

-the company’s tax identification number certificate

-a copy of the rent/lease agreement for the company’s office

-3 photographs (copies)

-particulars of the persons in charge of the main corporate functions

- Registering property (immovable property like with land revenue office)

Since we are a manufacturing firm employing ten or more workers, we must also register with the Chief Inspector of Factories and Establishments.

Building the Plant

To build the plant, we have to:

- Obtain cadastral survey map from Land Records Department

- Obtain zoning clearance

- Obtain project clearance from local authority (Ward Commissioner and City Corporation)

- Obtain project clearance and building permit from City Development Authority

- Receive excavation and foundation tax inspection from respective authority

- Apply for utility services (electricity, telephone, water and sewerage connection)

Environmental Considerations

As investors, we need to conform to certain environmental safety standards in order to get clearance certificates from the Department of the Environment (DOE). Environmental clearance must be obtained from the Department of Environment. The process will take us 15 days for projects with low levels of potentially adverse impact and 30 days for projects with significant impact.

Environmental Clearance Required for:

- Appropriate water-treatment plants

- Air-pollution-controlling devices

- Noise-pollution

- Safety measures

Project Proposals Must Contain:

- Appropriate environmental impact assessment

- Pollution-control measures

Running the Company

Intellectual Property Rights

The Government recognizes the importance of intellectual property rights (IPRs) for attracting foreign investment and is currently in the process of updating legislation in order to ensure better enforcement of such rights. Government has enacted the new law, “The Trademarks Act 2009” giving the scope to protect the services under International Classes 34-45.

International Obligations:

- Member of the World Intellectual Property Organization (WIPO) since 1985.

- Signatory to the Paris Convention on Intellectual Property from 1991.

Corporate Tax

As a Private Limited Company, we are entitled to a corporate tax of 37.5%.

Maintaining Labour Force

Bangladesh is very attractive for investment for her cheap abundant labour force. To hire labour force our business, we intend to comply with all the existing legal rules and regulations like following:

- Employment condition like minimum age, employment contract and compliance with ILO convention and recommendations.

- Compliance with existing labour laws including Workmen’s Compensation Act 1923, Payment Of Wages Act 1936, Maternity Benefit Act 1936, Employment Of Labour (Standing Order)Act 1965, Shops and Establishment Act 1965, Factories Act 1965,Industrial Relation Ordinance 1969.

Termination

Our company can be winded up either through:

- Our own decision to wind up or,

- Court’s Initiative to Wind up, if we fail to comply to legal issues or fail to pay our debts.

Market Analysis

The paper bag market and food package market both are still run by small scale producers who work on contract-basis with fixed customers. This market is still untapped by large-scale manufacturers. Some brands import their logo-attached bags/packages due to unavailability of quality products in the country.

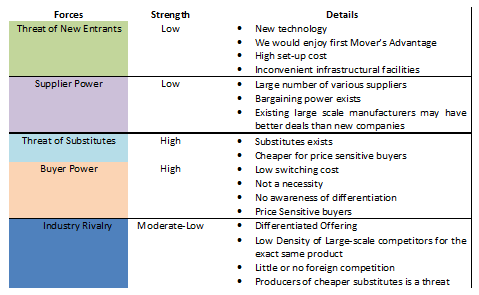

Porter’s Five Forces

PESTEL Analysis

PESTEL analysis stands for “Political, Economic, Social, Technological Environmental and Legal analysis” and describes a framework of macro-environmental factors used in the environmental scanning component of strategic management. The table below shows the PESTEL for the company.

Political | 1. Government regulations for manufacturing and importing machineries. 2. General strikes by opposite political parties caused huge loss to the businesses and industries. 3. Government initiatives to inspire eco-friendly business. |

Economic | 1. High taxation on imported machineries. 2. Unstable Economic situation. 3. Lower interest rates facilitate the borrowing on research of new products or technology. 4. Despite many internal problems like political instability, poor infrastructure, corruption, and insufficient power the economy maintains a 5-6% growth rate. 5. Bangladesh’s highly competitive labour and energy costs.

|

Social | 1. Lack of awareness of “green products”. 2. Attitude of common people to environmental issues. 3. Common tendency to buy cheaper product to increase profitability.

|

Technological | 1. Lack of technological advancement in the economy as a whole. 2. Lack of technological innovation in R&D sector due to insufficient investment. 3. Insufficient power supply. 4. Slow adaptation process with new technology. 5. Shortage of technically skilled labor. |

Environmental | 1. Opportunity to get abundant raw materials without harming the environment. 2. Environment friendly product. 3. Business marketing plans and Corporate Social Responsibility programmes should be linked with environmental issues. 4. Increasing awareness among the people about environment issues. |

Legal | 1. Legal issues regarding formulation of company. 2. Taxation policies. 3. Regulations of building manufacturing plant. 4. Compliance with existing labor laws.

|

SWOT

The company is starting its business in a new area of paper packaging industry. At present there is no tree-free paper making technology in Bangladesh. This business is both capital-intensive and labor intensive as we need to import expensive technology from abroad and huge labor force will be needed to continue the production process. Being an agricultural country Bangladesh provides an attractive opportunity for this industry. But still there are some obstacles which must be overcome; depicted in the following SWOT analysis.

Strength:

| Weakness:

|

Opportunity:

| Threats:

|

Market Demand and Supply Analysis

There are several factors that have a direct impact on supply. Companies try to cope up with the market demand. Here are quite a few factors that we identified having direct impact on supply.

Factors Affecting Demand:

Supply is directly related to change in demand and quantity demanded. Any decrease in demand may results in less supply. There are socio-economic characteristics of people, rate of inflation, fiscal policies and financing opportunities that affect the buying power of the customer and thus result in change of supply situation.

- Growth of customer base: The company will be focusing on business to business model, and a small portion of Business to Consumer model focusing on niche Marketing. Along with the economic development of the country the customer base is increasing day by day.

- Attitude to green product: People are becoming more concern about the environmental issues .this trend is so obvious that the idea of green marketing is becoming more and more popular.

- Inflation rate: Inflation rate is another crucial factor that could affect the buying power of the customers. At the same time, it influences rise in production costs that lifts the price upwards.

- Government regulation Government initiatives can boost up the demand in a substantial way. For example ban of polyethene had increased the jute product. If government emphasizes on green packaging it will ensure an overwhelming growth of the industry.

- Economic stability: Any instability in economy will affect the demand side as this is a B2B business.

- Political Environment: A country’s political environment has a greater impact on the supply curve. Political stability ensures risk-free growth of the economy and the business. It is assumed that politically unbiased neutral govt. is preferred for a sound economy Govt. type and policy influences investment decisions. For example, during the period of the interim govt., the govt.’s anti-corruption policy moved away potential customers and investors in fear of harassment regarding income tax.

Factors Affecting Supply Curve:

There are also factors that have affects on the supply curve.

- Availability of raw material: The business is totally dependent on domestic raw materials .so any factors related to the availability of raw materials will affect the whole supply chain.

- Labor efficiency: The labor force should be trained well to adapt to the new technology and process. The efficiency is supposed to be improve with the passage of time. Labor strike is also a critical issue.

- Power shortage: This is a large scale manufacturing business. Failure of power will hamper productivity ultimately raising the product price.

- Fluctuation in material cost: Fluctuation in material cost may encourage or discourage suppliers to invest. Recent upsurge of the materials discouraged new investors to invest in this industry which created more pressure on the existing companies. Increase in the production cost is the current issue the industry is facing. Production cost forces the investor increase the price. That might hamper the demand issue as well as the supply curve. Normally large companies are able to consume the extra burden of the cost. But small companies and the companies which are in the introduction stage often struggles to survive. The surveys conducted brought on two issues related.

- Infrastructure problem: Facility location and utilization can affect supply substantially. Infrastructural problem like transport facilities will affect the supply side. Delivery schedule should incorporate all the critical issues regarding transport and carrying.

Strategic Choices

In this section, we want to highlight the strategic choices that we will be making during the course fo staring in running our business. We intend to follow a 4Ps analysis, namely, product, price, placement and promotion. We have also discussed our marketing strategy and surviving strategy under this section as well.

4Ps

Product

Product is the goods-and-services combination the company offers to the target market. A product is anything that can be offered to a market for attention, acquisition, use or consumption that might satisfy a want or need.

ECOPAPER will primarily manufacture paper, which will be used for producing under-mentioned products:

Paper-based food packaging materials and products (food carrier, serving plate/glass, container etc]

Shopping bags

- Newsprint and writing papers

Product level:

The product serves on two levels-

- Core Benefit :

Paper is a versatile material with many uses. The most common is for writing and printing upon and it is also widely used as a packaging material, in many cleaning products, in a number of industrial and construction processes, and even as a food ingredient.

- Actual Product:

Paper and paper-made products possess product features, design, quality level, brand name and packaging. ECOPAPER will provide its consumers with specialized features and innovative unique designed paper-made products. ECOPAPER is the BRAND of diversified product range which will also provide customization and decoration-scope for its consumers as per direction.

Product Life Cycle (PLC):

PLC Marketing Objectives & Strategies are discussed in the following table:

| Objectives | Introduction | Growth | Maturity | Decline |

| Create product awareness and trial | Maximize market share | Maximize profit while defending market share | Reduce expenditure and milk the brad | |

| Strategies : | ||||

| Characteristics | Introduction | Growth | Maturity | Decline |

| Product | Offer a basic product | Offer product and service extensions, | Diversify products | Phase out weak items |

| Price | Use cost-plus | Price to penetrate market | Price to beat or match | Cut price |

| Advertising | Build product awareness among early adopters | Build awareness and interest in the mass market | Stress brand differences and benefits | Reduce to level needed to retain hard-core loyal |

| Sales Promotion | Use heavy sales promotion to entice trial | Reduce to take advantage of heavy customer demand | Increase to encourage brand switching | Reduce to minimal level |

Product Classification:

Products fall into two broad classes based on the types of consumers that use them-

- Industry product – product bought by individuals and organization for further processing or for use in conducting a business.

- Consumer product – product bought by final consumers for final consumption. It includes convenience product, shopping product, specialty product and unsought product.

ECOPAPER’s paper and paper-made products fall under both industry products and also under convenience Product section of Consumer Product. Convenience products are inexpensive frequent purchases, there is little effort needed to purchase them.

| MARKET CONSIDERATIONS | CONVENIENCE PRODUCT |

| Customer buying behavior |

|

| Price |

|

| Distribution |

|

| Promotion |

|

Product Mix:

ECOPAPER carries 3 different product lines.

Paper-based food packaging materials and products (food carrier, serving plate/glass, container etc]

Shopping bags

- Newsprint and writing papers

Price

ECOPAPER’s pricing strategy will be cost-plus pricing. As ECOPAPER is commencing its business, both the primary (paper) and secondary (paper-made) products must be priced by adding a make-up to the cost.

Placement

This refers to how an organization will distribute the product or service they are offering to the end user. The organization must distribute the product to the user at the right place at the right time. Efficient and effective distribution is important if the organization is to meet its overall marketing objectives. If an organization underestimates demand and customers cannot purchase products because of it, profitability will be affected.

ECOPAPER will use Indirect distribution which involves distributing product by the use of an intermediary – a wholesaler or retailer etc.

Promotion

For the promotion, ECOPAPER will follow these steps –

- Awareness : the consumer becomes aware of the new product, but lacks information about it

- Interest : the consumers seek information about the new product

- Evaluation : the consumers consider whether trying the new product makes sense

- Trial : the consumers try the new product on a small scale to improve their estimate of its value

- Adoption: the consumers decide to make full and regular use of the new product.

ECOPAPER will seek communication through the following ways:

Website:

ECOPAPER will have its own website designed with sample paper made products and related prices. All the necessary details required to customize products will be provided. Beside, ECOPAPER will also give pop-up advertisements in famous and regular web pages (i.e. facebook, yahoo, msn, also in car web pages)

Newspapers and magazine:

ECOPAPER will give advertisements monthly with its sample products mainly highlighting its environment-friendly features. Newspapers will include the most popular Bangla and English newspapers.

Billboards:

Billboards will be set up in strategically important points emphasizing the features and exclusive environmental attributes of the tree-free products.

Business Model

Ours is a Private Limited company where the owners will have equal power, through ownership of equal shares, in terms of decision making. For our business, the business model that we intend to follow will include the following facets:

Value Preposition

Our value preposition is producing quality products for business buyers that are environmental friendly and made from local raw materials. We will pay particular attention to the environmental awareness that our product will represent.

Infrastructure

The products will be made from local raw materials and processed through world class machinery imported from India. Our core competency lies in our scientific expertise, technologically-advanced facilities and equipment and excellent product quality.

Customers

Our target customers are businesses such as fast food chains which regularly make use of paper packaging in order to serve food or take-away and individual customers. We also intend to target .The distribution channel is mainly indirect, via intermediaries.

Value Chain Management

This section, the value chain management, is perhaps the most important section for a manufacturing firm like ours. This section is given particular emphasis as it is one of our goals to maintain healthy relationship with our value chain partners and enjoy the privileges that such good relationships harbour.

The pulp and paper industry depends on a long and integrated supply chain. The lead time from the first step to the last is long and it involves many steps operated by diverse participants in the process. There are four main processes or stages to this supply chain:

Although we have discussed production here, but because this is a crucial part of our business, we intend to explain it in further detail in the following section.

Procurement

This involves the operations directed towards providing for the raw materials and resources necessary for the production.

These raw materials will be obtained from various local sources including farmers for agricultural residues and fibre crops, ready-made garments sector for textile wastes, and from forest sector for wild plants.

Inbound logistics will include transporting the raw materials via from the sources in heavy truck-loads to our storage facilities in the outskirts of Dhaka.

Production

The production stage involves processing the raw materials and converting them to finished goods and products. There are a number of production processes involved; the raw materials need to be converted to tree-free thick paper before it can be shaped into boxes or shopping bags.

Quality is of the utmost importance in this stage of production and hence we intend to employ a Total Quality Management (TQM) approach to keep an eye on quality from the very beginning of the production process.

Production procedure has been discussed elaborately in the “Production section” of the report.

Distribution

Distribution essentially refers to outbound logistics – the logistics that are required to move the products to their respective customers or, in our case, businesses. For our business the distribution channels are both direct and indirect.

Transportation is conducted via road and through the use of trucks, vans and pick-up trucks.

Sales

The sales process deals with all demand planning issues including customer or market selections, pricing strategy, forecasting and order promising policies.

Our customers are businesses that need single-use shopping/carrier bags for customers to carry items from a store to home and also the fast-food shops and restaurants where wood-pulp paper-bags and Polyethylene [Plastic] or Styrofoam packages are used.

- Sales force:

We intend to pay special attention towards building a strong and reliable sales force that will not only provide any help that is required but will also deal with all kinds of complaints or queries regarding the finished products. Our sales force will educate the business buyers about the environmental advantage of our product and also teach our buyers about the importance of proper disposal and recycling of paper materials.

- After-sales Services:

We also aim to provide after-sales services in order to understand the satisfaction of our customers and also to sustain a healthy relationship with them. After-sales services provide a sense of reliability in terms of customer loyalty and hence will help us build better customer relationships.

The Value chain diagrams in the next few pages will be helpful in visualizing the actual processes taking place.

Production

Bangladesh is facing an acute shortage of fibrous wood based raw materials for the production of pulp and paper. On the other hand, the demand for paper and paper products is increasing day by day. This study reviews the availability and suitability of non-wood raw materials for pulp production in Bangladesh. It shows that Bangladesh has a huge amount of unused jute fiber, which is highly suitable for papermaking in Bangladesh. Other agricultural wastes like rice straw, dhaincha, golpata fronds, cotton stalks, corn stalks, and kash are also available and may be used for some pulp production. Given the different properties of these different non-wood fibers, jute pulp can be used as a reinforcing agent with other non-wood pulps for the production of high quality paper in Bangladesh.

“ecoPaper” Mill:

“ecoPaper” will havee a modern paper mill with highly complex industrial facility. Although the principles of papermaking have not fundamentally changed for many years, a papermaker from Imperial China or pre-industrial Europe would be hard pressed to recognize his craft amongst all the equipment of a modern mill. To explore how a present-day paper mill operates, let’s follow the path:

Stages and associated technologies [general processes] of paper mills:

1. Raw materials:

In general, timbers are used to manufacture pulp and paper. But ECOPAPER Company is established with the motto of GO GREEN by reducing the usage of timber in pulp making that will eventually lower down forest-destruction and carbon emission. And for these, the raw materials for ECOPAPER will be NON-WOOD fibers which are the very basic objective for setting up the company.

2. Chipping Machine

Raw materials are chipped into small pieces by knives mounted in massive steel wheels (used in chemical pulping process). Accepted chips are then stored in huge bins ready for the next process.

3. Chemical Pulping Process

The chips are ‘cooked’ by heat and pressure in caustic soda and sulphur. The chemical process is energy self-sufficient as nearly all by-products can be used to fire the pulp mill power plant. The chemical pulping process produces lower fiber yield than mechanical pulping, typically 50-60%.

4. Mechanical Pulping Process

Mechanical pulp yields over 90% of the non-wood as fiber is produced by forcing and hot water between enormous rotating steel discs with teeth that literally tear the non-woods apart. Alternatively, they can be pressed against grindstones which is why this process is also known as ground non-wood pulp. The special advantages of mechanical pulp are that it makes the paper opaque and bulky.

5. Hydra pulper

When the bales of non-wood pulp or waste paper arrive at the paper mill they are loaded onto a conveyor and passed into a circular tank containing water. This has a very powerful agitator at the bottom which breaks up the bales into small pieces. Hydrapulpers used mainly for handling waste paper are fitted with special devices for removing unwanted contraries such as wire, plastic, paper clips, staples etc.

6. Blend Chest

The stock passes to a blend chest where numerous chemicals can be added to obtain the required characteristics to the finished paper. Dyes are also added, as necessary, to color the paper. Dyes fix themselves to the cellulose fibers and are fast to light and water. Each grade of paper and board requires a very accurate blend of pulps and additives and the properties of the paper are continually monitored by computers during manufacture.

7. De-inking [Waste Paper]

Before printed paper [such as office waste and newspapers] can be recycled the ink needs to be removed, otherwise it will be dispersed into the pulp and a dull grey paper would result.

There are two main processes for de-inking waste paper – these are known as washing and flotation.

i. Washing

The waste paper is placed into a pulper with large quantities of water and broken down into a slurry. Contraries -such as staples – are removed using centrifugal screens. Adhesive particles, known as ‘stickies’ are removed by fine screening.

ii. Flotation

Again the waste is made into slurry and contaminants removed. Special surfactant chemicals are added which makes a sticky froth on the top of the pulp.

8. Refining

Before refining, the fibers are stiff, inflexible and form few bonds. The stock is pumped through a conicle machine which consists of a series of revolving discs. In this state, the fibers are pliable and have greater surface area, which significantly improves the fiber bonding. The properties of the paper are directly related to the refining process. Refining used to be called beating.

9. Screening and Cleaning

Pulps contain undesirable fibrous and non-fibrous materials, which should be removed before the pulp is made into paper or board.

Cleaning involves removing small particles of dirt and grit using rotating screens and centrifugal cleaners.

10. Papermaking Machine

The Paper Machine is a very large piece of machinery. A typical machine is about the length of two football pitches and around 4 metres wide. It can run up to speeds of 2000 m per minute – or 60 miles per hour! The machine itself consists of 7 distinct sections. The flow box, wire, press section, drier section, size press, calendar and reeling up.

The machine is operated by computer control. The computer will monitor the paper for moisture content, weight etc and computer screens will show pictures of the process and should any adjustments need to be made, an alarm will sound.

- Conversion and Printing

Once the paper is made, a great deal of it is converted into a product. Converters specialize in transforming reels and sheets of paper and board into a vast array of finished products for distribution such as boxes, cartons and stationery.

Producing Paper-made products from Paper

Once the paper is made, it will be converted into other categorized paper-made products. ECOPAPER’s primary plan focuses on producing below-mentioned product lines:

Paper-based food packaging materials and products (food carrier, serving plate/glass, container etc]

Shopping bags

- Newsprint and writing papers

For different categories, paper is needed to be of different thickness and manifestation. This will be adjusted during the paper manufacturing procedure according to the specification.

And the general machinery required for making the products of those three (3) categories are:

- Cutting Machine

- Paper Folding Machine

- Winding Machine

- Paper Slitting and Rewinding Machine

But more specified and product-definite machinery are necessitated in the cases of producing different product lines.

AUTOMATIC PAPER CUP MACHINE

The first stage: mainly finishes transmission of the paper cup’s sidewall paper, shaping sidewall and transferring them to the middle stage after shaped.

The medium stage: mainly finishes transmission of the cup-bottom paper, shaping cup-bottom, joining the shaped sidewall and cup-bottom, automatic transmission and discharging of the shaped cup, and curling the shaped cup’s edge.

The third stage: mainly includes 45 angle separating, preheating, curing bottom, rouletting, curling rim and so on mechanisms, which are the important parts in finishing paper cup machines

The fourth stage: mainly includes motor, reduction gear and so on. A frequency converter used to finish adjusting machine production speed and providing power.

Paper Bag Making

Modern Paper Bag Making Machines for manufacture of Flat and Satchel Paper Bags from kraft paper, vegetable parchment, poster, glassine and other papers of similar nature. These automatic paper bag making machines have been designed incorporating latest improvements and are available for manufacture of different ranges of paper bags for packing of foodstuffs, confectionery, readymade garments, tobacco and snuff, ice cream and many other items.

These paper bag making machines consist of the following units:

- Unwind Unit for paper Reels, with side adjustment, and Tension Control arrangement with hand brake.

- Pasting Units of side seam and bottom.

- Bag Cutting Device.

- Pressure Rubber Rings on the steel rolls as it fed to delivery drum.

- Rotary Drum Delivery with deli very board to stock bags.

Width of Paper Reel :

Width of paper reel be fed, is according to the width of the bag, and is obtained as under:

- Flat Bags: Twice the bag width plus 2-3 cm. for the length seam.

- Satchel Bags: Twice the bag width plus four time the depth of gusset, plus 2-3 cm. for the length seam. The length of bag or tube does not influence the width of reel.

Producing Newspaper & Writing Paper

The other two categories were mainly converted paper-made products where the final product matter more than the paper quality. But writing papers or newspapers need to be more smooth and high-quality. And to endow these specialties, these kinds of paper-making require some extra intermediary specialized stages:

1. Pulping

Digesting is the process of removing lignin and other components of the wood from the cellulose fibers which will be used to make paper. Lignin is the “glue” which holds the wood together; it rapidly decomposes and discolors paper if it is left in the pulp (as in newsprint, which is usually made from groundwood pulp with little or no chemical treatment). Since this is a “kraft” mill, the lignin will be removed by the action of sodium hydroxide (“caustic soda”) and sodium sulfate under heat and pressure.

2. Bleaching and Refining

The “brownstock” pulp will be free of lignin, but is too dark to use for most grades of paper. The next step will be therefore to bleach the pulp by treating it with chlorine, chlorine dioxide, ozone, peroxide, or any of several other treatments. The pulp will be beaten for various lengths of time depending on its origin and the type of paper product that will be made from it. At the end of the process, the fibers will be flattened and frayed, ready to bond together in a sheet of paper.

3. Forming the Sheet

Once the pulp has been bleached and refined, it will be rinsed and diluted with water, and fillers such as clay or talc may be added. This “furnish”, containing 99% water or more, is pumped into the headbox of the paper machine. From the headbox, the furnish will be dispensed through a long, narrow “slice” onto the “wire”. From the wire, the newly formed sheet of paper will be transferred onto a cloth belt (or “felt”) in the press section, where rollers squeeze out much of the remaining water.

4. Coating, Drying, and Calendering

After leaving the press section, the sheet encounters the drying cylinders. Between dryer sections, the paper may be coated with pigments, latex mixtures, or many other substances to give it a higher gloss or to impart some other desirable characteristic. After another round of drying, the paper sheet will be passed through a series of polished, close-stacked metal rollers known as a “calender” where it is pressed smooth. Finally, the sheet will be collected on a take-up roll and removed from the paper machine.

5. Cutting and Packaging

The new paper roll will be simply rewound on a new core, inspected, and shipped directly to the customer. The paper may also be cut into sheets at the mill, often by automatic equipment which accepts a roll of paper at one end and delivers packages of cut sheets at the other, already boxed and wrapped for shipping.

Technology

Only about 7% of the world’s paper is produced from tree-free materials today. The main drawback in tree-free papermaking to date has been the serious environmental problems related to conventional alkaline pulping.

Technology previously used for tree-free paper manufacturing was very inconvenient.Tree-free materials contain large amounts of silicates, which dissolve during conventional pulping, hindering the recovery of chemicals and dissolved solids. Spent liquor is typically discharged into waterways, causing excessive pollution. Due to inadequate chemical recovery, tree-free pulp mills typically consume large amounts of energy, which is normally generated using fossil fuels, resulting in high carbon dioxide emissions.

The Chempolis process solves all the main problems associated with tree-free pulping, and does not use either sulphur or chlorine chemicals. The process is based on the use formic acid as a pulping chemical. Acidic pulping conditions prevent silicates from dissolving, and make it far simpler to recover chemicals, dissolved solids, and water.

Formic acid can be fully recovered using evaporation and distillation, and some additional formic acid is formed in the process. Recovered dissolved solids can be combusted, generating sufficient energy to cover the needs of the process. This makes the process virtually self-sufficient in terms of pulping chemicals and energy, and eliminates carbon dioxide and sulphur emissions, as well as guaranteeing low operation costs and high operational efficiency.

Formic acid-based pulping makes totally chlorine free (TCF) bleaching to high brightness levels possible. TFC bleaching means that water can be recovered and recycled from bleaching filtrates, reducing water consumption and minimizing waterborne emissions significantly.

Finances

As ECO PAPER is quite a novice in the industry and is launching a totally new product which is currently unavailable in our country. There is no such company which is producing tree-free paper using domestic raw materials as eco paper does. As a result most of the required information for financial analysis is unavailable .This factors have to be assumed for the financial feasibility of the project. To validate the assumptions experts’ opinions have been taken. Considering the current market scenario of substitute product along with experts’ suggestions financial analysis has been worked out under these following assumptions.

As the required technology is unavailable in Bangladesh, it has to be imported from abroad. Import tax (about 7.5% depending on country and industry type) has been incorporated in their prices mentioned in capital expenditure.

- For depreciation of long term assets straight-line depreciation method has been used.

- There is no current market for tree-free paper .the target market is assumed to be the existing market of paper packaging products.

- The current market for paper packaging product is around BDT 70000 million.

- ECO PAPER will be trying to capture 1% market share within 5 years from its inception.

- The company will be financed by 20:80 debt-equity ratios.

- The loan will be interest-only long term loan from a govt. or commercial bank. An interest-only loan is a loan in which, for a set term, the borrower pays only the interest on the principal balance, with the principal balance unchanged. At the end of the interest-only term the borrower may enter an interest-only mortgage, pay the principal, or (with some lenders) convert the loan to a principal and interest payment (or amortized) loan at his/her option.

- The interest rate for the loan 13% and due after 10 years.

- The growth rate of the industry has been assumed to be 15% as in paper packaging industry.

- The company growth rate is assumed to be 20%.

- The inflation rate is 7.69% and prices are adjusted accordingly.

- The capacity utilization of the machines in the first year is assumed at 60% and expected to be growing at 5% annually.

- The cost of raw materials and labor has been assumed on the current market scenario.

- Required rate of return is 16.5%.

- To find out the break-even point weighted average contribution margin approach has been used.

- For payback period the cash flow is equally divided into 12 months in the 2nd year.

- As the utilities expense is likely to be variable cost, it is assumed to be 3% of sales.

- The company will adopt a 10% credit sale policy and the accounts payable will be 20% of cost of goods sold.

- The tax rate is 37.5% for private limited company.

- For cash flow indirect methods has been used.

The depicted in charts as shown as follows:

HR Strategy

Organizational Structure

Organizational structure refers to the way that an organization arranges people and jobs so that its work can be performed and its goals can be met. When a work group is very small and face-to-face communication is frequent, formal structure may be unnecessary, but in a larger organization like ECOPAPER, decisions have to be made about the delegation of various tasks. Thus, procedures are established that assign responsibilities for various functions. It is these decisions that determine the organizational structure.

ECOPAPER decides to shape its organizational hierarchy in the below-mentioned strategies:

Functional Departmentalization.

Every organization of a given type must perform certain jobs in order do its work. Key functions of a manufacturing company include production, purchasing, marketing, accounting, and personnel. Grouping jobs that require the same knowledge, skills, and resources allows them to be done efficiently and promotes the development of greater expertise. But, coordination of work across functional boundaries can become a difficult management challenge, especially as the organization grows in size and spreads to multiple geographical locations.

But, the different people and functions cannot operate completely independently. To a greater or lesser degree, all parts of the organization need each other. Important developments in organizational design in the last few decades of the twentieth century is the interdependence and improvement of the functioning of organizations in respect to this factor. It will flatten the organization, develop the horizontal connections and de-emphasize vertical reporting relationships. It will also simply eliminating layers of middle management. Being a very large manufacturing firms it will have four levels of management:

- Top management,

- Plant management,

- Department management, and

- Section management.

GREEN PAPER is determined to reduce the number of managers as part of a downsizing strategy; not just to reduce salary expense, but also to streamline the organization in order to improve communication and decision making.

In a virtual sense, technology is another means of flattening this organization. The use of computer networks and software designed to facilitate group work within an organization is expected to speed communications and decision making. Even more effective will the use of intranets to make company information readily accessible throughout the organization. The rapid rise of such technology will enable the virtual operations and boundary-less organizational activities possible – where managers, technicians, suppliers, distributors, and customers will be connected digitally along with being connected physically.

But in future, when the products will get highly diversified and intensively (superior) technology-based, then the company plans to adopt MATRIX ORGANIZATIONAL STRUCTURE.

Matrix Organizational Structure

One advantage of a matrix structure is that it facilitates the use of highly specialized staff and equipment. Rather than duplicating functions as would be done in a simple product department structure, resources are shared as needed. In some cases, highly specialized staff may divide their time among more than one project. Maintaining functional departments promotes functional expertise, while at the same time working in project groups with experts from other functions fosters cross-fertilization of ideas.

The disadvantages of a matrix organization arise from the dual reporting structure. The organization’s top management will have to take particular care to establish proper procedures for the development of projects and to keep communication channels clear so that potential conflicts do not arise and hinder organizational functioning. Top management will be responsible for arbitrating such conflicts, but in practice power struggles between the functional and product manager can prevent successful implementation of matrix structural arrangements. Besides the product/function matrix, other bases can be related in a matrix. Large multinational corporations that use a matrix structure most commonly combine product groups with geographic units. Product managers have global responsibility for the development, manufacturing, and distribution of their own product or service line, while managers of geographic regions have responsibility for the success of the business in their regions.

Organogram

Following is an Organogram depicting the structure of our company:

Action Plan

The action plan for this business plan is basically constructed in a Gantt chart format, to outline the basic strategies and actions that we will focus upon in the first five years of our production.

We have decided to make a chart for the first five years of our business, starting from year 1.

For ease of understanding, we have divided each year into quarters, named 1,2, 3 and 4.

Some activities encompass a number of years instead of being concentrated in any particular year. The actions basically follow these phases – planning, implementation and production, marketing and development.

The outline excludes details of finances and the capturing of market share. Details of entering, surviving and marketing-strategy framework for the third phase are discussed in detail following the chart.

Entering Strategy

Competitive strategies typically depend on the market environment and the positioning and product portfolio of the existing players. These are the basics:

Reduce price to penetrate an existing market. By introducing a product at a lower price than the pioneer’s, ECOPAPER can attract new customers who would not have otherwise purchased such a product –– in effect expanding the total market. Reduced price can also induce the pioneer’s current customers to switch. Still, this strategy is likely to result in reduced margins for ECOPAPER compared with other players in the market, unless ECOPAPER’s cost of production is relatively cheaper.

Focus on a niche market. Companies can compete by being innovative in the marketplace. The innovation may be radical or incremental.

The enhanced product can compete directly with existing similar products, or it can be positioned to attract a smaller segment of the existing market. In addition, the improved product or service can sometimes attract new customers that are not the current target for the existing product or service.

Develop new channels of distribution to access new markets or better penetrate existing ones. Focusing on existing markets, where your company has a good understanding of the environment, can prove less risky and bring quicker successes. This can be accomplished by repositioning the product or service through marketing, advertising, packaging and so on.

Technological innovation gives a company an edge for only a time, since incumbents catch on fairly quickly. Given that this is the case, new entrants should support their innovations with effective positioning, appropriate pricing and aggressive advertising.

Surviving Strategy

Even as new entrants attempt to redefine the business or formulate niche strategies to attack profitable industries and market segments, pioneers can fight back to retain their competitive advantage. The major strategies for the pioneers:

Increase the barriers to entry for later entrants

Innovate faster than the latecomers

Build a market-responsive

Flexible organization.

In most markets both pioneers and later entrants operate with incomplete information. Pioneers can take advantage of this by effective signalling mechanisms as a deterrent. For example, pioneers can cut price, signalling to potential new entrants that it is a low-cost industry and it will be difficult for them to survive. Pricing below variable cost, however, is illegal in most countries. On the other hand, new entrants traditionally focus on a few key segments of the market –– typically those that are subsidizing the cost to serve other segments of the incumbents. So, it is important for pioneers to understand their end-user segments and to adopt a differential pricing scheme to extract optimal rent from each of the segments.

Pioneers can also attempt to lock up the key channels of distribution, making it difficult for new entrants to get access to the market. In several industries and countries, however, it is not possible to get exclusive distribution rights. Pioneers can also offer special types of enhanced customer service packages or reward programs to make it harder for key customers to switch.

Another route, especially in the high-tech industries, is for a pioneer to remain innovative and launch the next generation of products –– or at least announce the next generation of products, thus deterring the entry of competition.

Finally, a responsive and flexible organization may be the most productive route, especially when the structure of an industry changes drastically or there is a seismic shift in the regulatory environment.

The underlying parameters for all these strategies are that companies should be aware of the market dynamics and have an organization that is flexible with the right culture to adapt, not only reacting to potential competition but also proactively developing their strategies. It is easier to lose a market-share point than it is to gain one.

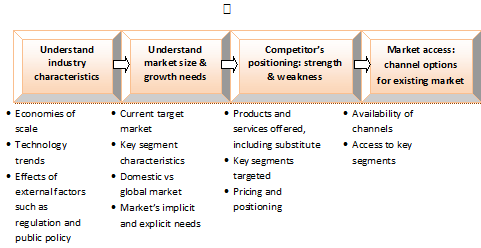

Marketing-Strategy Framework:

Having thoroughly analyzed the various strategies adopted by successful pioneers and later entrants, we have developed a framework both can employ to formulate strategies for growth, penetration or share retention, as the case may be.

The first component in our framework involves developing an understanding of the dynamics of the market. The critical areas to be analyzed are:

1) Those fundamental drivers of technology that may cause a significant shift in the market;

2) Changes in governance, such as any shifts in regulatory policies that might have a marked impact on the industry structure;

3) The size and growth of the potential market, and

4) The competitive profile.

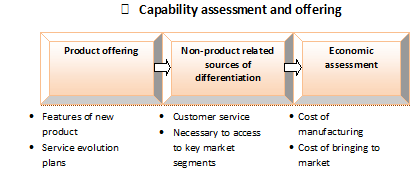

The second component of the framework involves conducting an internal assessment of your company’s capabilities and product offerings. Product or service development is an iterative process between developers and researchers, one involving marketplace feedback. Once a product is defined and the positioning determined, it is important to understand the economics of manufacturing. In a competitive environment in which a technology edge is short-lived, try to

think beyond simply making a good product in an economical way. Companies need to evaluate and develop non-product-related sources of differentiation, such as customer service, innovative ways to access end-users, creative marketing partnerships with other services such as frequent flyer programs, and so on.

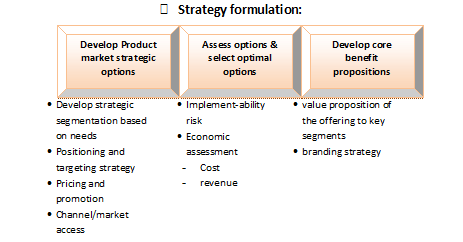

At the completion of external and internal assessment, a company is ready for the final component of the framework: the actual development of the product strategy. Strategic elements here include segmentation, positioning and decisions on marketing instruments.

One of the most important strategic elements is the timing of product entry. Should the company be the first to enter the market or a later entrant? Just what are the risks and rewards?

Again, there are some important tools available to facilitate scenario planning and decision making.

Understand market dynamics:

Contingency Plans

Since this is a new business, elaborate contingency planning is of utmost importance. Contingency planning is required to steady the organization during an unexpected change in the surrounding environment. These may be internal disasters, such as a fire, or external market-related issues, political uproars or natural calamities. For a new business, contingency planning is also required to shield the members if the company is incurring a steady loss and is unable to get the return from investments.

Risk Factors

Some risk factors associated with our business are:

- Lack of customer awareness and hence a probability of loss

- Threat from giants in the market and strict Government regulations

- Insufferable price wars from competitors and hence a chance of diminishing

- Political instability in the country – strikes and price hikes; threat of terrorist attacks

- Environmental threats such as earthquakes, flooding

- Internal threats such as fire or worker injuries

Recovery Strategies

We plan to initiate a temporary Business Contingency Planning Team for our company in order to deal with the unexpected situation when and if they arise. These will be experts in crisis management and will help the company to recover from any obstacles that this company faces, including the initial hurdles that of a new business. Some of our strategies are:

- Extensive marketing efforts in the initial stage

- Effective cost management strategies

- Keeping up with Government policies and legal issues

- Ensuring safety of workers and plants

- In the unlikely event of a crisis, business functions will be recovered in priority sequence based upon the classification of the function as agreed with business senior management and implemented jointly.

- Creating a contingency planning infrastructure with equipments and backup to effectively deal with unforeseen natural or national crisis.

Growth Trajectory

We plan to grow our business into an industry that is self sufficient, venturing into production of all kinds of paper products and exporting them abroad. And since nowadays more and more businesses are being attentive towards eco-friendly products, in near future, more scope of ECOPAPER may pop out. And since the customization and automated paper-product options are very new to this country, more businesses may get attracted to it.

We are expecting a steady growth rate of 20% and aim to capture 1% of the market in the next 5 years.

As we become veterans in the business, we aim to employ multidimensional growth strategies to maintain steady growth rate using multivariate data analysis methods and give specific emphasis on economic growth as well.

However, at the core of this, we believe that growth should not only be quantitative, but qualitative as well.

Growth Management

As a company grows, the growth management becomes an important issue for the managers. Growth management is essentially requires a sound growth plan, with:

- Attainable goals

- Flexible opportunity-oriented process

Growth Management is important to us for a number of reasons:

- Globalization. The world is becoming the market place. Companies must learn to contend with planning growth in a variety of nations, not just domestically. Companies must become versed in cultures of countries where they do business – and speak the languages of the people in those countries.

- Understanding Markets. It is not sufficient to just package and ship domestic products. To grow, companies must know the intimate details of how to sell in many nations – distribution channels, pricing, hidden elements.

- A Questioning Nature. It is becoming more necessary to be “hands on with details.” People involved in managing growth need to know what questions to ask, when, and how.

- Adeptness to Technologies. A variety of new technologies are impacting all businesses. These must be understood by those directing growth. Trends with these must be identified and directed. New computer software, manufacturing methods, and other advancements in technology must be utilized to boost productivity.

- Building Teams. People must subscribe to the vision of the company in which they are managing growth. They must understand the role, direction, and philosophy of the business, and work to make it happen.

- Communications. We believe communications is a business discipline just like finance, sales, or manufacturing. We diligently practice communications at all levels. We work to have employees at all levels understand the company. The core of our efforts in this area is simple, plainly worded mission statements and fundamental management systems.

We would focus on:

- Building a strong, strategic foundation – through establishing market niches, building relationship with value chain members, maintaining flexibility to adapt t changes in the environment

- Emphasis on leadership development – through harnessing personal growth to enhance decision-making skills

- Human Resource Commitment – Human resources must be cultivated with the same, if not greater, diligence as capital, property, and equipment.

Conclusion

EcoPaper is an initiative to bring a very important notion in our country and make people aware of a rising concern – to save the environment through saving woods and forests.

This EcoPaper has focused primarily on the role played by major paper purchasers and policymakers on continuing to create the demand for environmentally sound papers. But individuals, too, can have an impact. Organization staff members and even the general public can add to the pressure for more environmentally sound papers by implementing the following recommendations for influencing the largest paper users.

We are at a fortunate time in the development of environmentally sound papers. Several new high grade deinking pulp mills have opened or are in the development process, enlarging the potential for recycled paper production. Technological breakthroughs have solved problems with processing many contaminants such as toners. Several producers and distributors are strongly dedicated to providing kenaf and hemp papers. In addition, paper mills have dramatically reduced the amounts of water and energy they use and the pollution they produce compared to even fifteen years ago.

Paul Hawken, in his book The Ecology of Commerce, quotes from the futurist Willis Harmon, “Business has become, in the last century, the most powerful institution on the planet. The dominant institution in any society needs to take responsibility for the whole. Every decision that is made, every action taken has to be viewed in the light of, in the context of, that kind of responsibility.” Hawken follows that up with, “Business is the only mechanism on the planet today powerful enough to produce the changes necessary to reverse global environmental and social degradation. Doing that will depend in large part on the willingness of customers to change what they buy, how they buy, and from whom they buy their products and services.”

All of us have responsibility for shaping the future. Our consumption choices form a significant part of that responsibility. Paper is one of the most ubiquitous purchases in our economy. Choices in buying something so simple can mean so much for our own quality of life and for future generations.