Glass capacitors are used where the ultimate performance is required for RF circuits. Glass dielectric capacitors offer very high levels of performance, although their cost is high when compared to many other forms of the capacitor. Typically a glass capacitor will have a relatively low capacitance value. The values of glass capacitors may range from a fraction of a picofarad up to two to here thousand picofarads. As such these capacitors are used mainly in radio frequency circuit design.

Glass capacitor construction

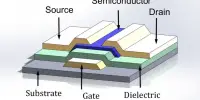

The construction of glass dielectric capacitors is relatively straightforward to understand. The capacitor consists of three basic elements: the glass dielectric, aluminum electrodes, and the encapsulation. However, the assembly of the glass capacitors is undertaken in a manner that ensures the required performance is obtained.

As the capacitance between two plates is not always sufficient to provide the required level of performance, the majority of capacitors use a multiplayer construction to provide several layers of plates with an interspersed dielectric to give the required capacitance.

Although the glass plates are always flat, and tubular forms of construction are not applicable, the glass capacitors are usually available with leads emanating in either a radial or axial form. Essentially the leads either exit the encapsulation at the side or the end.

While the performance of glass capacitors is exceedingly high, this is also usually reflected in the cost – it can run into many pounds or dollars for each component. As such glass dielectric capacitors are reserved only for the most exacting RF requirements, often on low volume products where cost is not such an issues as it is in high volume products. The supply of glass capacitors is also limited to a small number of manufacturers and suppliers, and the capacitors may not be available ex-stock.

Information Source;