1.1Background

This Internship Program as well as this report is an indispensable of my courses of Business Administration. After completion of our courses in the different areas of studies, students are sent to different reputed Business organization to

acquire the real life experience. So I was placed in Cottonfield to understand the merchandising system of the RMG industry in Bangladesh and selecting the topic on the basis of my findings like “Cottonfield as a merchandiser”

1.2 Origin of the report

In today’s world only academic education does not make a student perfect to become competitive with the out side world. Internship is highly needed to gain idea, knowledge and experience.

Northern UniversityBangladesh one of the reputed private universities in Bangladesh, has designed the curriculum of the MBA course such a way that the international standard graduates will be produced. After completing 63 credit hours, one student needs to go for further 3 credit hours internship program in a commercial organization.

Cottonfield is a place where I could learn the business dealings. This factory has introduced some modern garments scheme that has got high market demand. As it maintain the pace with the competitive business world, its activities culture, philosophy and style leads an intern student to be the best at any field of working life

As an internship student I have got the opportunity to work with this organization for three months and acquire idea about real business world.

1.3 Objectives

The key objective of the report are as follows:

- Identify the merchandising division’s work of Cottonfield

- Identify the merchandiser duties and responsibilities

- Identify the opportunities and threats for knitwear firms

- Theoretical aspect of merchandising division

1.4 Methodology

The report has been prepared based on secondary data such as – the published company annual reports, various publications, and company documents. Some sort of primary data was collected by with the supervisor and employees of the company.

1.5 Internship at Cottonfield

My 12 weeks at the Cottonfield as an internee had been the most enjoyable time of life. Doing my internship at one of the leading factory in Bangladesh, I believe I have accumulated an experience unmatched to any other.

I am extremely happy to work in such a report. Though as a student of finance and marketing it was a new situation to me, however it was totally new practical experience to me, it was very much enjoyable to me.

The working environment of merchandising and administration department of the Cottonfield is conductive and friendly. The stuffs are specialized in their respective fields. Each of them works on their own and there is supervision from the top. The motivation the staff, I believe comes from the very sense of responsibility for his or her work.

My overall experience had been very absorbing and I believe internship period at the Cottonfield will definitely help me a lot in building my future life.

2.1 Mondol Group

Mondol group is a vertical integrated knit garments manufacturing and exporting composite unit. The group started its business in 1991 with a small garments sewing factory. At present the group has facilities for yarn spinning, fabric knits, dyeing finishing and garments cutting sewing, finishing, packaging and exporting.

Mondol group has the folloing member units

1. Mondol Textile Ltd.

2. Mondol Yarn Dyeing Ltd.

3. Montex Fabric Ltd.

4. Montex Fabric Ltd.

5. Mondol Securities Ltd.

6. Montrims Ltd.

7. Appolo Fashions Ltd.

8. Cotton Concern (BD) Ltd

9. Cotton Club (BD) Ltd

10.Cottonfield (BD) Ltd

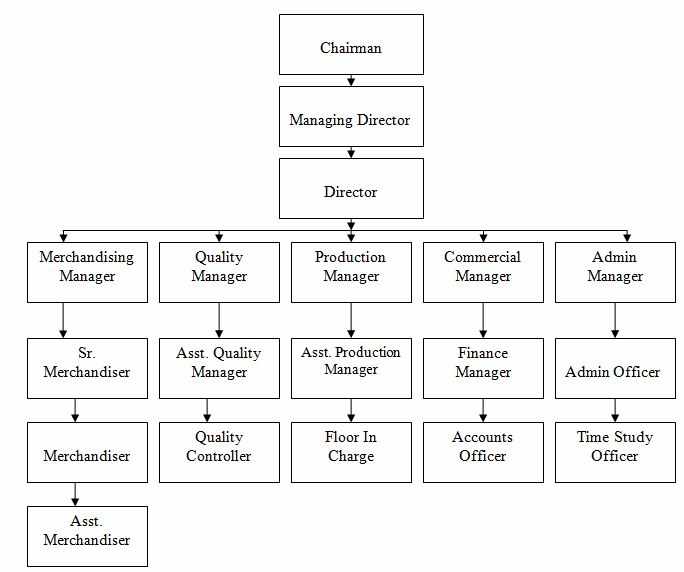

2.2 ORGANIZATION CHART

2.2.1 COMPANY PROFILE

Company Name : COTTONFIELD (BD)LTD.

100% Export Oriented Knit Garments.

Head Office Address : House No # 8, Sector # 11, (1st Floor)

Sonargaon Janapath Road, Uttara New

ModelTown, Dhaka-1230, Bangladesh.

Factory Address : Shima Complex, Plot # 23, Shataish Road

Gazipura, Tongi, Gazipur.

Year of Establishment : 2004

Location of the Factory : Towards Gazipura after Tongi

Only 15 KM Baridhara Diplomatic Zone

Only 10 KM ZiaInternationalAirport.

Area of the Factory : 77,500 Sft

( 5 Floors, Each Floor 15,500 Sft.)

a) Ground Floor : Fabric Store

b) 1st Floor : Office, Go Down

c) 2nd Floor : Sewing Floor, Iron, Folding Section

d) 3rd Floor : Sewing Floor, Iron, Folding Sectio

e) 4th Floor : Cutting Section, Mosque, Dinning Hall.

Trial production : Started from 1st December 2004

Commercial Production : Started from 1st February 2004

Products Manufacturing : T- shirt, Polo shirt, Tank top, Vest, Trousers.

LIST OF MACHINE

One Needle Lock : 140 Sets

Over Lock : 200 Sets

Flat Lock : 25 Sets

Button Hole : 04 Sets

Button Stitch : 04 Sets

Rib Cutting : 05 Sets

Back Tape : 02 Sets

Production Capacity Per Day : Polo shirt 10,000pcs Or T- shirt 20,000pcs.

Number of Employees : 1100

2.3 Fabric Inspection

Fabric inspection is a major operation in the quality control process. The purpose of fabric inspection is to ensure that the fabric inspection is confirmed and the defect label is with in acceptable tolerance.

There are three stages at which inspection may be carried out as follows:

- Gray fabric inspection

- Intermediate inspection

- Final inspection

2.3.1 Gray fabric inspection:

Gray fabric inspection will be generated on up to b

uyers requirement for standard quality. Fabric type, with, different type of defects will be checked here. Minimum 10% the fabric will be checked by using 4 point method.

Requirements:

- Inspection table

- Arrow sticker

- Measurement tape

- Inspection form

- GSM cutting machine

- GSM measurement meter

- Highlight pen

- Ball pen etc.

2.3.2 Intermediate Inspection:

Intermediate inspection, the standard speed of the wrapping role is 20 meter per minute. The standard lighting distance is 1 meter. Light should be displayed in 90 degree angel and view from 45 – 90 degree angel.

2.3.3 What is 4 point method?

The 4 point system also called the American Apparel Manufacture Association (A.A.M.A.) point grading system for determining fabric quality. This is widely used by producers of apparel fabric.

Fabric defects are assigned point value based on the following:

Size of defect Penalty

- Defects length up to 3 “ 1 point

- Over 3” up to 6” 2 points

- Over 6” up to 9” 3 points

- Over 9”, any hole 4 points

Different type of defect

A gray fabric can contain many type of defect as follows:

- Spot

- Slab

- Napes

- GSM hole

- Oil spot

- Knot

- Dia mark

- Uneven Dyeing

- Oil mark

2.4 STORE

Store room is a place where we store something for safety or protection. Store is very important part in a factory. A well decorated store can give significant advantages. Two types of stores are available in the factory.

Store for raw materials

Store for accessories

List of goods:

Store for raw materials.

Different types of fabrics available in the raw materials store like:

- Single jersey

- Double jersey

- Rib fabric

- Fleece

- Interlock

- Pique etc

Here goods arranged in color wise, fabric type wise. Five large self’s are available to store raw materials. There is no use of electric light or electricity in the store for fire protection. A weight measurement machine is available here to measure the weight of raw materials like fabric.

Store for accessories.

Trims and accessories are available here:

- Different types of trims

- Different types of Label

- Sewing thread

- Tissue paper

- Poly

- Tag pin

- Price sticker

- Button

- Zipper

- Shoulder tape

- Scotch tape

- Needles etc.

Here goods arranged in self’s and lay in floor in carton.

2.5 CUTTING ROOM

Cutting can be divided into two.

1. Trail/ test cutting

2. Bulk cutting

- Trial/ test cutting: The marker ratio of trial cutting should be different then bulk cutting. In trial cutting we should try to cut all sizes & minimum quantity.

- Bulk cutting: We should not go for bulk cutting without approval of Q.C. department & pattern correction team.

2.5.1 Dispatch of cut work

- Collect the order quantity along with color, size breakdown for style or P.O.

- Collect the fabric & other specified accessories for cutting

- Collect the fabric GSM report

- Collect the shrinkage report

- Check with pattern section for confirming all shrinkage in corporate in pattern or not

- Collect the fabric test report

- Fabric relax for shrinkage

- Determine the fabric width

- Make a marker as per ratio

- Lay the fabric

- Keep minimum 8 hours for lay shrinkage

- Check the marker for grain line & counting everything is ok or not

- Cutting

- Numbering

- Checking part

- Send for printing, embroidery etc

- Collect from the printing room

- Additional work: part replacement

2.5.2 Cutting room equipment:

- Cutting table

- Cutter or knife

- Scissor

- Numbering machine

- Hand gloves

- Lay cutting machine

- Pattern machine

- GSM cutter

- GSM scale

- Marker pan

- Marker paper

- Measurement tape

- Piping machine

2.6 SAMPLE SECTION

Sample is the physical form of buyer specification or style or design. In other way, we can say Sample is the representation of mass production.

Different type of sample:

Marketing or Sales man sample

(From available/ ready stock)

Counter or reference sample

(Based on buyers specification but using available raw materials)

Fit sample

(Using actual raw materials)

Pre-production sample

(Before production & different size sample)

Shipping sample

(After production & buyer counter sample)

2.6.1 Sample making procedure

- Which sample/ Type of sample

- Sourcing of raw materials

- Sourcing of accessories

- Making a pattern as per buyers requirement

- Making sample

2.6.2 Sample approval procedure

Making a sample as per buyers requirement

↓

Sample forward to QC team

↓

Sample review as per buyers requirement

↓

Approval signal from QC team

↓

Sample send to buyer

↓

Review of buyer’s technical team

↓

Comments given by the buyer

2.7 SEWING SECTION

Sewing operator sew garment according operation with sewing allowance. In every sewing line has a check point where check the sewing mistake.

We use different sewing method in this section. Effective sewing system combined with new planed layout and new sewing machine can give a significant advantage in many market areas.

Most used/ common system

- Conventional Bundle System

- Progressive Bundle System

- Modular Manufacturing System

- Toyota Sewing System

CONVENTIONAL BUNDLE SYSTEM

In this system, operators collect the bundle from storages and return it after completing the sewing. The sewing machine lay out is random.

PROGRESSIVE BUNDLE SYSTEM

In this system, operators collect the bundle from racks and passes it to the next operator. The sewing machine lay out is sequence.

MODULAR MANUFACTURING SYSTEM

It is very effective system in the sewing method. Each and every operators are multy skilled. This system applied for fashioned garments.

TOYOTA SEWING SYSTEM

In this system, operators stand to work and machine lay out in a “U” shape. A supervisor is available to help with technical information.

2.7.1 Different types of machine are use in sewing section:

- Flat lock machine

- Over lock machine

- Single needle machine

- Plain machine

- Button hole machine

- Button attach machine

- Piping machine

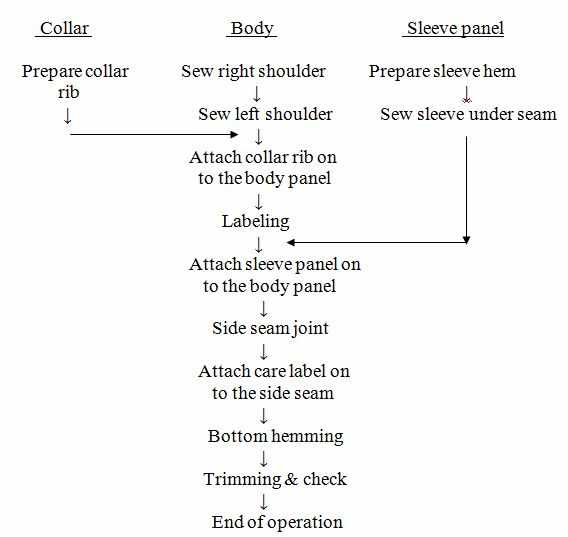

2.7.2 Process Breakdown of a T – shirt

2.8 IRONING & FINISHING

Ironing and Finishing department is the most important department. It is the last stage of finish garment.

Ironing – object of ironing is to giver the actual shape of the garments.

2.8.1 The types of ironing equipment which are available in the factory are:

- Boiler machine

- Iron

- Long table

- Body & sleeve board

- Two pipes (One for steam and another for water)

2.8.2 Finishing – item those can be matched by he finishing equipment are:

- Main label

- Care label

- Size label

- Price label

- Hang tag

- Tissue paper

- Poly

- Carton

2.8.3 Finishing Department Machine

- Tag gun machine

- Spot remover machine

The vendor Marketing Program of COTTONFIELD offers short term Trade Finance & Services to qualified apparel exporters in Bangladesh. Although in the year 2007 COTTONFIELD has approved of term long facility of maximum US$ 2.5 million with a maximum tenor of three years under the program, it had proposed to hold the term loan facility till there is a clear picture of the garments export.

3.1 An Order Procedure for a Buyer

- At the beginning of a season we received Design Pack. After that we have to Quote Price, which we have provide with Sample and Open Costing formet.

- Next we received Order Confirmation messages from buyer with Excel chart & Confirm Sheet.

- After received contract sheet we have to send for generate PO sheet. At that time we will receive PO and LC.

- Later we have to send Fit Sample within 15 days.

- And later on we submit Pre Production Sample after receiving the 1st Fit Sample approval.

- Later we get Pre Production Sample approval, than we go to Bulk production.

- After Bulk production, we send Shipment Sample to Buying House.

3.2 Job Responsibilities of Assistant Merchandiser

3.2.1 After confirmation of order:

- To work under the guidance of his superior merchandiser

- Learn to follow up check list

- Learn hoe to match zipper

- Learn about different counts of sewing threads.

- Learn how ton weight fabric

- Learn how to measurement CBM

- Study export documents

- Booking fabric with buyer approval

- Booking accessories with buyer approval

- Find out construction and weight of fabric

- Arrange Lab dip & Yarn dip approval

- Take sample fabric approval

- Collect wash report

- Make trims card

- Make fabric card

- Get fabric quality approval

- Arrange fabric test

- Make shade card & get approval

- Collect color wise breakdown

- Collect size ratio

- Collect packing instruction

- Collect carton & poly measurement

3.2.2 Before & During Production

- Check whether bulk fabric and accessories are in house

- Check whether sample is approved for bulk production

- Check whether swatch card is approved by buyer

- Check whether trims card is approved by buyer

- Check whether factory PP sample is approved by buyer

- Arrange inline inspection

- Check production status & wash status

- Check style & measurement

- Check wash effect

- Arrange poly and carton

- Discuss the merchandising manager

- Collect production per hour

- Collect sewing and finishing status

3.2.3 During after shipment:

- Send shipment sample to buyer

- Send copy of document to buyer

- Check export section when goods arrived in sea port in time.

3.3 Calculating the fabric consumption for a basic style T – shirt

After the Lab Dip approval, factory will ready to manufacture the fabric of a particular order. The merchandiser will booking how much fabrics he need to prepare sample and how much for production. Calculation the fabric consumption given below:

Say: Fabric type 1oo% cotton single jersey

Fabric weight – 140 GSM

Body length – 76 cm

Body width – 120 cm

Sleeve length – 26 cm

Sleeve rolling – 3 cm

Bottom rolling – 3 cm

Neck length – 42 cm

Neck width – 5 cm

Processes loss – 10% (Fabric)

Processes loss – 5% (Neck rib)

We know that,

Fabric length = Given length + allowance + Bottom rolling

= 76 cm + 1 cm + 3 cm

= 80 cm

Fabric width = Given width + allowance

=120 cm + 2 cm + 2 cm

=124 cm

Sleeve length = Given length + allowance + Sleeve rolling

= 26 cm + 1 cm + 3 cm

= 30 cm

Total fabric length = (80 cm + 30 cm)

= 110 cm

FORMULA = (Length x Width – 10000 x GSM – 1000) + 10%

= (110 cm x 124 cm – 10000 x 140 – 1000) + 10%

= 0.210056 kg/piece

= 0.210056 kg x 12

= 2.52 kg/dz

Neck length = Given length + allowance

= 42 cm + 2 cm

= 44 cm

Neck width = Given width + allowance

= 5 cm + 2cm

= 7cm

FORMULA = (Length x Width – 10000 x GSM – 1000) + 5%

= (44 cm x 7 cm – 10000 x 150 – 1000) + 5% (GSM = 150)

= 0.004851 kg/piece

= 0.004851 x 12

= 0.058212 kg/dz

3.4 Calculation the costing of a basic T – shirt

In the price quote stage merchandiser makes the price of the unit price of an order. This price quote is prepared by the consultation of their buyer and it can be changed one or two times. Calculation the costing of a basic T – shirt given below:

Say, Single jersey = $ 4.00/kg

Neck rib = $ 4.50/kg

Cost of manufacture(C M) = $5.00

Trims = $ 4.00

Commercial = $ 4.00

Body fabric consumption = 2.52 kg/dz x $4.00 = $10.08

Neck rib consumption = 0.058 kg/dz x $4.50 = $ 0.26

Cost of manufacturing (CM) = $ 5.00

Trims = $ 4.00

Commercial = $ 4.00

————————————————————–

Total Cost = $23.34/dz

4.1 Financial position of Cottonfield(CFL) with other factory

Bangladesh is the 12th largest garments manufacturing nation in the world. The garments sector is divided into the textile and the readymade garments (RMG) segments. The textile segment is sub-divided into a number of activities, which include spinning, weaving, and fabric processing; and the RMG segment includes knitwear and woven items.

Cottonfield is one of the prominent third generation factory in RMG sector. Now I try to comparison the financial wealth of Cottonfield with other three factories. Those are:

Delta

Keya

Radiance

4.1.1 Authorized capital of Cottonfield Vs others factory

BDT in million)

Cottonfield Delta Keya Radiance

2007 4500 3500 3000 5500

2006 3000 4000 3000 5000

In the year 2006 and 2007 Radiance authorized capital is higher than other factory. In 2006 Cottonfield authorized capital is lower, but in 2007 Cottonfield authorized capital hold second position with Radiance.

4.1.2 Paid up capital of Cottonfield Vs others factory

BDT in million)

Cottonfield Delta Keya Radiance

2007 1500 2000 1700 1400

2006 1300 1600 1650 400

In the year 2006 and 2007 the paid up capital of Cottonfield is only higher than Radiance. But lower than Delta and Keya.

4.1.3 Total capital of Cottonfield Vs others factory

BDT in million)

Cottonfield Delta Keya Radiance

2007 2500 4500 2500 2200

2006 2100 3500 2200 2000

In the year 2006 total capital of Cottonfield is higher than Radiance and in the year 2007 it is higher than Keya and Radiance

4.1.4 Total asset of Cottonfield Vs others factory

(BDT in million)

Cottonfield Delta Keya Radiance

2007 15000 60000 50000 45000

2006 13000 40000 35000 42000

In the year 2006 total asset of Radiance is higher than others factory and in 2007 Delta total asset is higher than others factory.

4.1.5 Profit after tax of Cottonfield Vs others factory

(BDT in million)

Cottonfield Delta Keya Radiance

2007 700 1000 600 300

2006 400 600 500 200

In the both of year 2006 and 2007 profit after tax of Delta is much higher than others factory. And in the year 2007 Cottonfield hold third position.

4.1.6 Fixed asset of Cottonfield Vs others factory

BDT in million)

Cottonfield Delta Keya Radiance

2007 400 600 200 400

2006 450 500 150 300

In the both of year 2006 and 2007 fixed asset of Delta is higher than others factory. And Cottonfield hold the second position in terms of fixed asset.

From the comparisons of financial of four factories, it is clear that most of cases Delta hold the top position. Cottonfield performs well in some cases. But it is clear that in all the cases Cottonfield done well from previous year. To see it’s up growing performance, it is my assumption that the Cottonfield will be the leader in the upcoming days.

4.2 SWOT ANALYSIS 0F COTTONFIELD

4.2.1 General Description

SWOT analysis is a strategic planning tool used to evaluate the Strength, Weaknesses, Opportunities, and Threats involved in a project or in a business venture. It involves specifying the objectives of the business venture or project and identifying the internal and external factors that are favorable and unfavorable to achieving that objectives.

The aim of any SWOT analysis is to identify the key internal and external factors that are important to achieving the objectives. SWOT analysis groups key pieces of information into two main categories:

Internal factors – The strengths and weaknesses internal to the organization.

External factors – The opportunities and threats presented by the external environment.

The internal factors may be viewed as strengths or weaknesses depending upon their impact on the organizations objectives. What may represent strengths with respect to one objective may be weaknesses for another objective. The factors may include all of the 4Ps; as well as personal, finance, manufacturing capabilities, and so on. The external factors may include macroeconomic matters, technological change, legislation, and socio-cultural changes, as well as changes in the market place or competitive position.

| Strength – Well develop plan, high quality machinery and location |

facility.Weakness – Depend on imported raw materials, lack of knowledge.

Opportunities – Annual domestic demand, subsidy facility and cost

savings.Threats – High price of raw materials, decrease of quota system.

4.2.2 STRENGTH

- Strong financial capacity.

- Combination of modern technology.

- A group of skilled and trained human resource with national and internal expertise.

- Strong and Efficient management.

- A strong linkage between the all companies.

4.2.3 WEAKNESS

- Port of Chittagong is very slow in handling containers due to lack of cranes.

- Low productivity of labor.

- Dependent on 100% imported raw materials and technology.

- Difficult to handle with always upgraded new technology.

- Administrative cost is comparatively higher

- Over dependence on imported raw materials.

4.2.4 OPPORTUNITY

- Very higher quality product which have a good demand in international market.

- Sub contracts from Canada.

- Market for a large portion of product is ensured within the all companies of the sister concern of Mondol Group.

- After full integration of the group, the administrative cost might be lower.

- There is a good opportunity for marketing, more production in future.

4.2.5 THREAT

- Very competitive national and international market.

- Many new companies are coming in front with new product and new technology.

- Dependency of foreign countries for raw materials.

- National and international yarn market is always fluctuating.

4.3 Overall Findings

- Cottonfield has a modern technology, efficient and dynamic management & commitment to the highest work standards.

- There are clear structure and accountabilities supported by well understood policies and procedures to guide the activities of the factory’s management both in its day-to-day business in the areas associated with internal control.

- The factory is operating through a well defined management structure headed by Managing Director under whom there are various department heads and according to hierarchy, various senior mid level management staffs. The Managing Director and departmental heads meet at regular interval

- The factory always recognizes the importance of human resource development and makes considerable investment for acquisition, development and retention of talented and dynamic professionals through its programs for trainings, allocation of responsibilities & authority, performance appraisal, job enlargement & enrichment.

CONCLUSION

With the backward linkage that the woven sector does not have, knitwear is becoming a more competitive sector. With positive responses from the experts and the owners alike, the knitwear sector is likely to have more opportunities in the future, which they are likely to use to overcome the threats.

However, if proper measures are not taken, it may face difficulties, like competition from India. Even a few years back India lagged behind Bangladesh in terms of the production facilities. Now, with the support from the government, the manufacturers over there are able to produce at a lower cost, compared to Bangladesh. Therefore, the knitwear sector should get adequate support measures from the government, as well make a coordinated effort to be able to fight in the global arena.

As it is not up to the required standard in terms of efficiency and technological equipment, proper measures should be taken to build up the infrastructure to be able to be as competitive as possible. The knitwear holds a bright prospect.

![Report on Industrial Attachment at DIVINE TEXTILE LIMITED [ Part – 2 ]](https://assignmentpoint.com/wp-content/uploads/2013/03/divine-group-128x100.jpg)

![Report on Beximco Knitting Ltd [ Part-2]](https://assignmentpoint.com/wp-content/uploads/2013/04/Beximco-Knitting-Limited-200x100.jpg)