Introduction of Merchandising Department:

A merchandising division surrounds the concept of the target customer and translates customer preferences into a product line for the rest of the apparel firm. Merchandising is the planning, development and presentation of product line for identified target market with regard to prices, assortment, styling and timing.

Function of Merchandiser:

The merchandising process interacts with and may be limited by the business plan and the marketing plan. The primary components of merchandising activities included following—

1. Line planning is the formulation of the parameters that guide line development and presentation and influences sourcing and production process

2. Line development has subcategories of the concept, creative design, line adoption, and technical design. Line development included the actual merchandise that will fill out the line plane through some combination of product development and selecting goods at wholesale.

3.Line presentation with subcategories of internal, wholesale, and retail Line presentation involves process required to evaluate the line and make the line visible salable. .Line presentation results in evaluation and sale of the product offering.

Marketing Section:

A marketing division is responsible for “shaping and strengthening the image of a company and it products through promotion, optimizing sales opportunities and developing alternate strategies for corporate growth.

Responsibilities of marketers:

Conduct and report customer research.

Position the firm relative to target markets.

Position the firm relative to the competition.

Develop the firm’s image.

Propose marketing programs

Propose advertising /promotion strategies.

Forecast sales.

Procurement section

The basic function of Procurement is as follows:

Right product or materials

Right time

Right quantities

Right price

Right quality

Right delivery.

Sample Section:

Basic patterns or blocks are developed to reflect the firm sizing standard and fit. A basic block pattern is a set of pattern pieces for the simplest garments of the particular type that reflects a set of measurement in the sample size. The terms basic blocks sloper, and master pattern may be used interchangeably. Firms have basic blocks for each type of product in their product line — skirts, pants, shirts, jackets, etc

Style blocks are variations of the individual pieces of the basic block that have been modified to include styling case. Style blocks contain both comfort and styling case.

Draping involves developing a pattern by manipulating fabric directly on a body form. To reduce costs, some firms prefer to have their designers work with Muslin first before fashion fabric are draped since the pattern may be draped several times before it is finalized

Production Department:

Cutting section

sewing section

Finishing Section

Maintenance Section

Cutting section Sewing section

Finishing Section

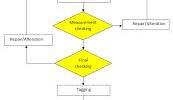

Organgram of production:

Production department:

Production-along with marketing, merchandising, operation, finance is one of the

Essential functions in apparel manufacturing. Apparel production involves the conversion of materials (INPUT) into completed, salable garments (output) flat pieces of goods are cut, shaped, assemble, and trimmed as they converted into specific styles to meet customer needs. Production process may be carried out in a firm’s own plant and sourced from other firms located in any place. Production plants specialize in a certain types of materials and finished goods because of the limitation of equipment, skills and expertise available.

CUTTING SECTION:

Cutting is the production process of spreading (Sectioning, carving, serving ) a spread into garment parts that are the precise size and shape of the pattern pieces on a marker. The cutting process may also involved transferring marks and notches from the marker to garments parts to assist operator in sewing. Chopping or sectioning a spread blocks of pieces goods may precede precision cutting of individual pattern shapes. This is often done to allow for accurate machine of fabrics design or easier manipulation of a cutting knife.

Fabrics pieces may be cut to predetermined length for matching patterns or for additional processing such as screen printing. Spreads of plaid fabrics may be pre sectioned into block so the design on the fabrics can be perfectly matched before cutting to the shape of the pattern pieces. Per sectioned pieces may be also be also garment parts knitted to specific finished lengths such as sweater bodies. Per sectioned pieces such as leather or other specialty fabrics may be spread and cut as a single ply or laid up and cut as a multiple – ply spread.

The cutting process may also involve in sewing.

Function of cutting in charge:

The most important functions of cutting in charge:

Examine incoming orders and width and availability of pieces goods

Determine volumes size ratios, sectioning procedure for making marker

Determine whether the file maker are available or new ones are needed

Determination specification for optimum marking and fabrics utilization

Determining most effective use of spreading and cutting equipments

Issuing orders for making spreading and cutting

Function of pattern and marker:

All the patterns in each size of a style are verified that is cheeked very carefully before sending them to cut order planning. Pattern verification includes checking the followings—

Correctness of grade incremental

Competitively of reading with styles specifications

Length and alignment of adjoining seam allowances

Notch placement and alignment with adjoining pattern pieces

Placement of internal markings \Placement of grain marking.

Sewing section:

Sewing section can be divided into following sub-section on the basis of their functions:

Function of production managers:

Production managers are responsible for managing in a firm’s styles through conversion process. Managing production in owned facilities involves people, process, equipment and facilities. Managing production through vendors involves evaluation of production facilities, negotiation of price quotas and delivery and monitoring quality

Production managers are the head of production department. He is who takes all the decision in the development of the desired requirement of the buyers. He takes all the decision in the decision making table. His main job may be divided into planning and coordinating function.

Planning:

Production standards are used in production planning to do the following:

Estimate the rate or production for completion of each operation

Determine the required capacity for an order or style

Determine production start dates and completion dates for orders

Plane the daily volume that should be completed

Determine the back inventory needed to support the work flow

Determine how many operators and machine should be performing each operation

Function of floor chief:

The function of floor the floor chiefs are to control the floors attain the maximum output from the floor. He coordinates among the worker in the floor. He is accountable to the production manager. He follows the instruction received from the product manager.

His main function is as follows:

Floor layout

Setting line layout

Manpower setting in a line

Allocation of manpower

Setting machine and accessories

Setting over time

Allocation of the line for particular style to increase productivity

Helping or supporting the line chief

Coordinative functions with other departments like cutting, finishing, quality and sub store as well as sample section

Allocation of line chief and supervisor in a particular time

Function of line chief:

Line chief is accountable to the floor chief. He coordinates with the supervisor and operates as well. The following are the functions of line chief.

Target achievement

Quality assurance

Proper utilizations of worker

Line layout and assembly of the machine in a particular line as per line layout diagram

Allocates operators for particular job

Sequential of production process in the assembly line

Machine layout

Allocation of folders and accessories

Coordination among the supervisors and floor chief.

In case of problem, which can not be solved by the supervisors

Preparation of the over time in case of needed

Solving bottleneck

CUTTING SECTION:

Cutting is the production process of spreading (Sectioning, carving, serving ) a spread into garment parts that are the precise size and shape of the pattern pieces on a marker. The cutting process may also involved transferring marks and notches from the marker to garments parts to assist operator in sewing. Chopping or sectioning a spread blocks of pieces goods may precede precision cutting of individual pattern shapes. This is often done to allow for accurate machine of fabrics design or easier manipulation of a cutting knife.

Fabrics pieces may be cut to predetermined length for matching patterns or for additional processing such as screen printing. Spreads of plaid fabrics may be pre sectioned into block so the design on the fabrics can be perfectly matched before cutting to the shape of the pattern pieces. Per sectioned pieces may be also be also garment parts knitted to specific finished lengths such as sweater bodies. Per sectioned pieces such as leather or other specialty fabrics may be spread and cut as a single ply or laid up and cut as a multiple – ply spread.

The cutting process may also involve in sewing.

Function of cutting in charge:

The most important functions of cutting in charge:

Examine incoming orders and width and availability of pieces goods

Determine volumes size ratios, sectioning procedure for making marker

Determine whether the file maker are available or new ones are needed

Determination specification for optimum marking and fabrics utilization

Determining most effective use of spreading and cutting equipments

Issuing orders for making spreading and cutting

Function of pattern and marker:

All the patterns in each size of a style are verified that is cheeked very carefully before sending them to cut order planning. Pattern verification includes checking the followings—

Correctness of grade incremental

Competitively of reading with styles specifications

Length and alignment of adjoining seam allowances

Notch placement and alignment with adjoining pattern pieces

Placement of internal markings \Placement of grain marking.

Sewing section:

Sewing section can be divided into following sub-section on the basis of their functions:

Function of production managers:

Production managers are responsible for managing in a firm’s styles through conversion process. Managing production in owned facilities involves people, process, equipment and facilities. Managing production through vendors involves evaluation of production facilities, negotiation of price quotas and delivery and monitoring quality

Production managers are the head of production department. He is who takes all the decision in the development of the desired requirement of the buyers. He takes all the decision in the decision making table. His main job may be divided into planning and coordinating function.

Planning:

Production standards are used in production planning to do the following:

Estimate the rate or production for completion of each operation

Determine the required capacity for an order or style

Determine production start dates and completion dates for orders

Plane the daily volume that should be completed

Determine the back inventory needed to support the work flow

Determine how many operators and machine should be performing each operation

Function of floor chief:

The function of floor the floor chiefs are to control the floors attain the maximum output from the floor. He coordinates among the worker in the floor. He is accountable to the production manager. He follows the instruction received from the product manager.

His main function is as follows:

Floor layout

Setting line layout

Manpower setting in a line

Allocation of manpower

Setting machine and accessories

Setting over time

Allocation of the line for particular style to increase productivity

Helping or supporting the line chief

Coordinative functions with other departments like cutting, finishing, quality and sub store as well as sample section

Allocation of line chief and supervisor in a particular time

Function of line chief:

Line chief is accountable to the floor chief. He coordinates with the supervisor and operates as well. The following are the functions of line chief.

Target achievement

Quality assurance

Proper utilizations of worker

Line layout and assembly of the machine in a particular line as per line layout diagram

Allocates operators for particular job

Sequential of production process in the assembly line

Machine layout

Allocation of folders and accessories

Coordination among the supervisors and floor chief.

In case of problem, which can not be solved by the supervisors

Preparation of the over time in case of needed

Solving bottleneck

Function of Supervisor:

Supervisor is called the first line the executive in the floor. Their functions as follows:

Supervisor operates and helpers in all the operation

Constant monitoring the of materials and the accessories

Ensure quality output

Ensure productivity

Solving operational problems in case of productivity

Solving bottleneck

Training operator to achieve desired output

Development of skilled operator

He is a motivator

Supervising operators and helpers in a line

Allocation of job to operators and helpers

Development of helper to operator

Function of operator:

Operator is the one who occupies the maximum number in the assembly .They are the one who really sweat for the productivity in an organization. Their outcome is the outcome of the company. They are the one who contribute more in the garments sectors the operator is the most important person in the factory.

The function pf operator is as follows:

Assembling parts

Proper handling of machine and parts

Ensures quality

Ensures capacity target

Ensures measurement of garments as per instruction

Ensures allowances as requirements and instruction

Ensures productivity

Reduce wastage, alter and rejections

Informing supervisors in case of handicap in regards to operations and machine as well

Ensures utilization of numbers to reduce quality rejects

ORGANOGRAM OF FINISHING SECTION

Finishing section:

Finishing section help in the development of exports before shipment. The whole proceeding before shipment has been made in this department

Function of the finishing section:

The functions of the finishing section are as follows:

Process control

Pressing

Folding

Hang tag and others attachments

Poly bag

Assortment

packing

Pre shipment audits

Shipment

Organogram of Maintenance section

Maintenance section:

Maintenance department work in the development of the process through or by the help of machines. Their job is to ensure fault free machines at good conditions. Ensures delivery of right machines at the right place.

The functions of maintenance department work in the development are as follows:

Supply of equipment for assembly and pressing

Discuss issues related to equipment selection

Explain mechanization and automation relative to general and special purpose machines

Examine the basic components of sewing machines work aids and finishing equipment

Examine the effect equipment on product quality and performance

Procurement of those machines required for the production process

Preventive maintenance

Training of man in the section for specialized machines

Break down maintenance

Supply of accessories like folder or attachments

Function of maintenance in charge:

Understanding layout and preparation of layout

Understanding the requirement of machine

Changing a machine from heavy to light and vise versa

Understanding the requirement of folder and preparation of folder

Setting m/c as per layout and should adjust the m/c according to the fabrics used

The accessories should adjusted in the m/c where it will be needed for quality productivity

Attending pre- production meeting

Making a meeting daily with his subordinated for batter time utility and output as well

Understanding floor layout and utilization of space

Responsible for the development of proper lighting at the factory

Responsible for proper flow of efficiency

Responsible for all kinds of maintenance

Attending to the operator at all time to solve the mechanical problem at the line to avoid to any kind of hindrance or flow of productivity

Keeping better understanding of quality and to assess quality management

He must understand fabric and the nature of fabric

Keeping good liaisons with the production, cutting, quality department

Responsible for preventive maintenance and break down maintenance

Regular servicing of m/c before placement another styles

Responsible for proper maintenance of accessories and spare part

Proper recording of all the materials

Ensures flow of electricity at the required place

Function of mechanics:

Attending floor

Fixing machine at the lines

Adjustment of the machine

Ensuring proper adjustment of the m/c to insure quality and productivity

Adjusting or fixing accessories in the m/c like folder or spares or change of needles if needed

Helping in the layout and line setting

Setting m/c as per line layout

Understanding the needed of machines in a process and adjust the m/c accordingly like light to heavy to light

Servicing of m/c

Preventive maintenance

Breakdown maintenance

Commercial Department:

Packing is a critical element in a getting the product to the distribution center or customer in good condition. The type of containers used and how the goods are packing in those containers affect the condition of the merchandise and the efficiency of the shipping process.

Utilization of container space can impact shipping cost for international shipping. A firm pays to ship a full container and if it is not full the cost in the same

Export and import section :

Major function of Export and import section :

Making all the procedures for the clearance of the good from point of origin to the sea port to a manufacture

The arrangement of shipment from the point of production to the point of sale

Involved in the development of negotiation in most of the cases

Responsible for the customer formalities

Arranging procedural matters in the development of back to back L/C based on master L/C.

Responsible for receiving the materials both local and foreign

Insurance is one of the functions

Damage claims

Banking Section

Major function of Banking Section:

Issuance of quota

Involved in the development of arranging all the formularies like BGMEA EPB and shipment

Recommending for correct utilization of fabrics/yarn/ acrylic/wool

Giving permission for inner bond sub-contract of bonded warehouses goods

Issuing utilization declaration (U/D), export orders for clearance of raw materials factories.

Helping disposal of stock lost of fabr

Human Resource &Administrative Department

Information system selection

Recruitment & career development and training section

compliance section

Inventory management section

Human Resource &Administrative Department:

People are a firm’s greatest resource. Employees and their degree of motivation have more to do with the success of a firms then any other single factor. Motivation may be compensation for completed work recognition by peers or management, a feeling of accomplishment a desire to learn. Trainer and managers need to be aware of motivational factors in developing training programs and compensation systems. Motivation is very closely aligned with job satisfaction.

The basic function of Human Resource:

Recruitment and placement

Designing salary and wages

Development of employees through training

Counseling

Motivation employees for the achievement of the organization goal

Development of “sense of belonging”

Bringing organization goal and the individual goal in the same wave line

Creation of better environment

Designing training need and the development of the personal to increase productivity

Ensuring payments both monthly and over time on a specific time and date

Retrenchment of employees

Administrative action in case of defalcation

Declaration of incentive

Upgrading employees

Information system section

Function of Information Technology:

Save time and money

It saves energy and reduce wastage in all spheres of life

It brings more productivity outlook

Increase efficiency

Move to the department of professionalism

Help in the development of prompt decision process

visualization of the processes predictable

Education of theft and wastage of man and material ensures

Inventory Management section:

Inventory is defined as money the system invests in things that it intends to sell. Units of inventory have value based on the total investment in the item that may be well above the original cost. Value is added to materials throughout the production process and the value remains in the system until the style of sold

Market value of items may decrease with prolonged storage. Fashion goods tend to become obsolete rather quickly.

Three cost factors must be considered in evaluating inventory:

The original cost of the goods

the cost of maintaining the inventory including interest on borrowed money and restricted cash flow

The value added to the original materials

Conclusion:

Inventory management has become a more sophisticated field because of computerization of inventory data, production planning, and real time production control, And costing systems. It is common for investment in inventory.

The major function of inventory management

Right procurement and storing

Making inventory to coincides as per order

Ensures proper storage functioning to avoid pilferage and damage of the products

procurement of the product at the right time and the right quantities in many cases

proper issues of the material at the floor

Proper recording systems

Proper placement

![Report on Industrial Attachment at DIVINE TEXTILE LIMITED [ Part-3 ]](https://assignmentpoint.com/wp-content/uploads/2013/03/divine-group-128x100.jpg)