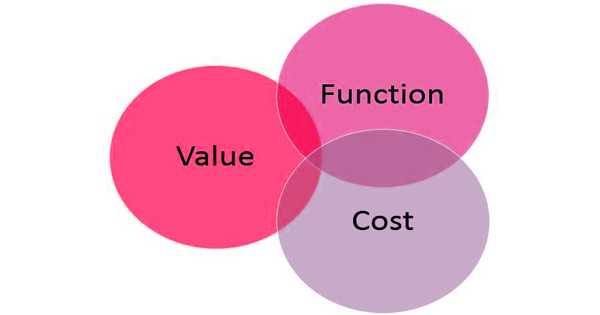

Value engineering is a methodical, organized approach to providing essential functions in a project at the lowest possible cost. It is also referred to as value analysis. Value engineering is the systematic examination of factors influencing the cost of a product or service in order to devise methods of achieving the specified purpose while maintaining the required standard of quality and reliability of the target cost. It encourages the substitution of less expensive materials and methods without sacrificing functionality.

It is focused solely on the functions of various components and materials, rather than their physical attributes. The main aim of value engineering is to achieve a product’s target cost, by:

- Identifying improved product designs that reduce the product’s cost without sacrificing its functionality

- Eliminating unnecessary functions that increase the cost of product.

Functional analysis is required for value engineering. This procedure entails separating a product into its various components. In the case of automobiles, for example, the function could include style, comfort, performance, reliability, quality, attractiveness, and other factors. The value of an item is defined as the most cost-effective method of producing it without sacrificing its purpose. A price or value is assigned to each element, which reflects the amount the customer is willing to pay for the product. Companies typically conduct customer surveys and interviews to obtain this information.

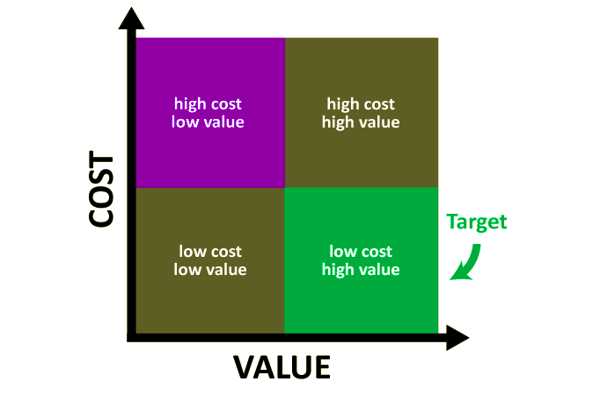

The sum of the values for each function yields the estimated selling price, from which the target profit is subtracted to yield the target cost. The price of each function of a product is weighed against the benefits perceived by customers. If the function’s cost exceeds the benefits to the customer, it should be eliminated, modified to reduce its cost, or enhanced in terms of perceived value so that its value exceeds the cost.

Value engineering is typically performed after the design process has been completed, but it is best performed before the design is completed to allow the experts to incorporate the option of using alternative materials and methods. As a result, value engineering is the technique used to analyze all aspects of an existing product or component in order to determine the lowest cost required for specific functional requirements.

Process of Value Engineering

- Functional Analysis

- Standardization of Components and Parts

- Alternatives of Functions

- Value-cost Analysis

- Re-engineering

Areas of Value Engineering

- Improvements in product designs

- Changes in materials’ specifications

- Modification in process methods

- Decision to make or buy a component