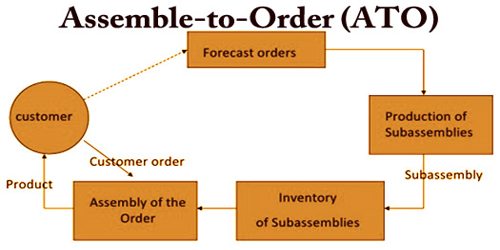

Assemble-to-Order (ATO) could be a production model where the ultimate goods are produced once the manufacturer receives the order from the purchasers. The components are already produced and stored at the location. This method is different from the build to order method where the manufacturer starts producing from scratch after the customer places his order. It’s advantageous for the customer as he gets the customized product briefly time and also the price for keeping the inventory reduces for the manufacturer.

ATO strategy is a hybrid between the make-to-stock strategy (MTS) and the make-to-order strategy (MTO). A make-to-stock strategy is one where products are fully produced ahead. the thought is to create a list that matches expected or anticipated consumer demand. This method would encompass setting a production level, build up inventory, so attempting to sell the maximum amount of assembled products as possible. It’s used mostly for high-volume goods, consumables, and items which will be bought in bulk or as one unit.

The make-to-order strategy involves ordering parts and assembling them based on the specific orders placed by customers and takes a longer time to deliver the final good to the customer.

Example: One well-known example of the ATO technique is the success of Dell Computers. The company allows the customers to choose among several processors, monitors, disk drives, etc. There can be numerous combinations of the components which a customer can choose. The producer keeps the stock of parts and assembles it once he receives the order from the customer and delivers the customized product in almost no time.

The ATO strategy attempts to mix the advantages of both make-to-order and make-to-stock getting products into customers’ hands quickly while with the merchandise to be adapted or altered in certain ways, as per customer request. In most cases, the time and costs related to building the merchandise from its components are minimal. However, the time and costs to create the components, which are usually ordered from a supplier, may be considerable.

Enabled by technology, advancements in production processes and inventory management systems have played a big part in making assemble-to-order strategies a reality. Add cheaper methods of shipping products, and the strategy been a boon for product customization opportunities.

Advantages of ATO:

- Subparts can be replaced in the future once they become obsolete

- Higher inventory turnover ratio, leading to low cost

- The capability of producing the customized product

- Quick delivery

Disadvantages of ATO:

- Unreliability of forecasts

- Management of sub-assembly parts

- Dependence on the quality of the final assembly

Consider a multi-national company that sells customizable smoothies. In order to avoid stocking up on finished smoothies which will perish over time, the corporate uses an assemble-to-order (ATO) strategy whereby they top off on all the ingredients but assemble the finished product (i.e., smoothie) when the customer places an order. Companies like Body Energy Club (US) and Booster Juice (Canada) depend on such a business model.

Information Sources: