Introduction

Shabab Fabrics Ltd (SFL has been incorporated in the year 2006 with the aim to meet the growing demand of high quality terry towel products for the global market. Initially the core competency is on terry towel manufacturing but the product range will steadily be enlarged to include the whole gamut of house hold textiles. SFL has the capability to offer a complete terry towel product range. The goal of the SFL is to become the preferred partner for sourcing high quality terry towel products from Bangladesh.

Strong business ethics, excellences in business, creating a productive work environment, continuous improvement through sound corporate governance and dynamic employee Engagement have been at the function of the organization to become the leading terry towel factory in Bangladesh.

1.General information about the mill

1.1 Name of the mill: Shabab Fabrics Limited

1.2 Owner of the mill: Khandokar Abdul Muktadir

1.3 Location and site plan of the mill:

Bashil, Hazirbazar, Bhaluka, Mymensingh

1.4 lay out of the mill

A= Preparatory section

B1 = weaving section (DOBBY)

B2= weaving section (jacquard)

C = Dyeing section

D = Office + swing + dormitory

E = Boiler and Generator room

F = Main entrance and exit

G = vehicle way

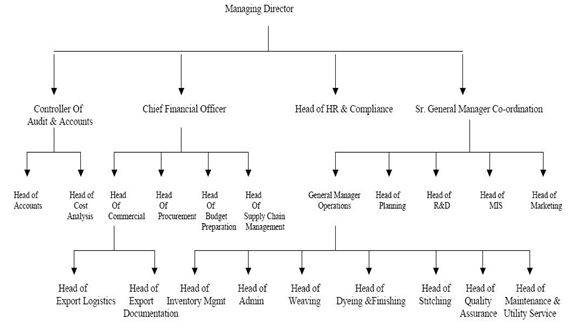

1.5 organizational structures:

1.6 total man power and section-wise man power: 650 persons

1.7 total production: 20 ton per day

1.8 total turnover: 33$ million /year

1.9 vision: To offer high quality and eco friendly products at most completive price through integration of creativity & expertise itself as well as for the society.

Mission: To obtain customer satisfaction by ensuring highest quality of products in a competitive price.

2 .Product mix and description of various products

2.1 Name of the product mix and detail description about the products

2.1.1 Beach Towel

Generally, a beach towel is a little larger than a bath towel. They are soft, fluffy and thick because their main purpose is to provide comfort while one relaxes by the pool or on the beach.

TYPES

Besides the normal ones, multipurpose and convertible beach towels are also available. These towels can be converted into a back pack, tote or sleeping bag, deck chair cover and even into an auto seat cover. These towels have storage in the form of pockets and closures. They are very useful during windy condition.

STYLES AND PATTERNS

Beach towels are usually in bright colors. They have interesting patterns printed or woven into them, most of them being cool, fun and youthful. They also come in bright and colorful stripes. Kids’ beach towels come with printed or woven pictures of their favorite Disney characters and super heroes.

MATERIALS USED

Beach towels are made of the following materials:

• Cotton

• Terrycloth

• Tencel

USES

Beach towels are used for different purposes like:

• To dry oneself after swimming.

• For wiping sand from the body or objects.

• Worn for privacy while changing clothes in public places.

• As a cushy spot while sunbathing and help the user relax.

2.1.2 Bath Towel

The main purpose of a bath towel is for drying one’s body after a bath or shower. They are generally woven with a soft and absorbent loop or pile and are thus used to wick the water away from the body.

TYPES

In accordance to their specific use and size Bath towels are divided into:

• Wash Cloth Towel

• Hand Towel

• Standard Bath Towels

• Bath Sheets

2.1.3 Washcloth Towel

Washcloth are the smallest form of bath towels. They are also called facecloth or washrag. Washcloth are cheap and sold mostly in bulk.

TYPES

Because washcloths are used for very personal purposes, there are disposable washcloths meant for perineal and personal cleaning. They are ideal for guests and for the hospitality industry. There are also scented wash cloths which contains aqueous solution to moisturize the skin while cleaning. They are used mostly in hospitals and nursing homes. The disposable washcloths can be heated once or twice to a select temperature.

STYLES AND PATTERNS

Washcloths are mostly square in shape, though they can also be manufactured according to specification. Washcloths come in different colors, mostly in plain and checked pattern. There are knitted forms of washcloths for a more invigorating bath. Washcloths are available in bulk or in set with other matching towels.

MATERIALS USED

A washcloth is made of highly absorbent material. The material can range from medium weight to heavy weight. The texture of a washcloth should be able to stimulate and invigorate the body and at the same time exfoliate dead skin cells. The materials mostly used to make washcloth are:

• Cotton

• Terry Cotton

• Linen

USES

Washcloths are used for:

• Lathering

• Scrubbing

• Washing the face and body

2.1.4 Hand Towel

• Hand towels are not just a larger substitute for washcloths. They should be coordinated with the other bath towels. The general size of a hand towel is 30×60 cm. They are usually positioned near the sink, hung on a hanger or loop.

•

MATERIALS USED

Hand towels can be made of different materials. The main criteria are they should be soft and absorbent. Some of the most common materials used for making hand towels are:

• Cotton

• Tencel

• Silk

STYLES AND PATTERNS

Hand towel has the maximum designs and patterns, they are unlimited. They can have embroidery work on them. There are knitted hand towels. There are hand towels with crochet, patchwork and prints. Hand towels are available in many colors. Stripe and embellished hand towels are also available. Hand towels can be personalized with monograms or names embroidered on them.

USES

The many uses of a hand towel are:

• A hand towel is used for drying hands after washing.

• Besides the general use for drying one’s hands, hand towels are also used for promotional purposes

• Hand towels customized with the company/organization logo are used as a means of advertisement

• Hand towels are very popular during corporate outings and events like golf. They come with a grommet or hook to be fixed to the golf bag

2.1.5 Standard Bath Towels

Standard bath towels are the ones that most people use on a daily basis. Their main function is to provide maximum absorption to the user.

TYPES

Besides the normal bath towels, there are bath towels for infants, toddlers and kids. The infant’s and toddler’s bath towel can have hoods, which keep them warm after a bath. Kid’s bath towels also come in the poncho style, it keeps them warm besides the pool or on the beach and also makes changing very convenient.

MATERIALS USED

While making a bath towel, importance is given to the absorbing capacity and the ability to dry quickly. Some of the most common fabrics used for making a regular bath towel are:

• Terry Cloth

• Terry Weave Microfiber

• Cotton

• Microfiber

STYLES AND PATTERNS

There is a vast array of styles and patterns of bath towel in the standard size. They can come in the form of solid colors. White color is the most popular because of its fresh and crisp looks. Some people preferred to have their initial/s monogrammed on the towel. Neat embroideries at the corner of the towel are also very popular. For infants, toddlers and kids, the patterns are interesting and come in bright colors. Some manufacturers offer custom digitized and monogrammed towels according to specifications.

SHAPE AND SIZE

A standard bath towel is rectangular in shape and its popular size is 30″×60″ (75×150 cm). But people of a larger frame find the size of a normal bath towel not comfortable. So, they opt for a larger variety known as a bath sheet.

2.1.6 Bath sheets

Bath sheets are the largest of all the bath towels. Many people prefer bath sheets to the standard bath towels because of the more area for absorption.

MATERIALS USED

Absorbency and comfort are the main purposes for the use of bath sheets, so high quality fabrics are the first choice for the manufacturers. Utmost care is taken to the texture and finish of the towel. The most common types of fabrics used for making a regular bath sheets are:

• Terry Cloth

• Terry Weave Microfiber

• Cotton

• Microfiber

• Fleece

SIZE

They can be six feet or more in length. The general size of a bath sheet is bath sheet is around 60″ x 32″. For larger people, the normal bath towel is not satisfactory. So, they still preferred extra large bath sheet which is much larger than the normal bath towel.

STYLES AND PATTERNS

White is the most popular color for bath sheet. They also come in a variety of colors with beautiful patterns but plain, single color bath sheets are preferred. Bath sheets can be customized according to the specification of the customers. Monogram, embroidery and applique are also used to add variety to the bath sheets.

USES

• To dry oneself after a bath, shower or a swim.

• They can also be used as a makeshift sarong.

• They can be wrap around to provide warmth.

• They can be used to provide a cushy spot for sunbathing.

2.2 Steps of operations for developing each product.

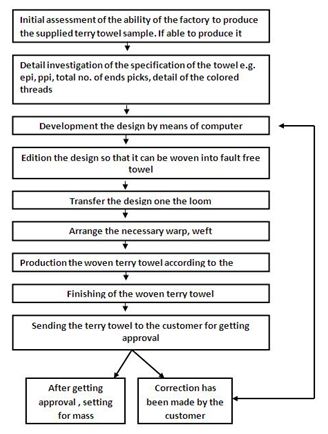

2.3 Flow chart diagram for producing a woven terry towel in Shabab Fabrics Ltd.

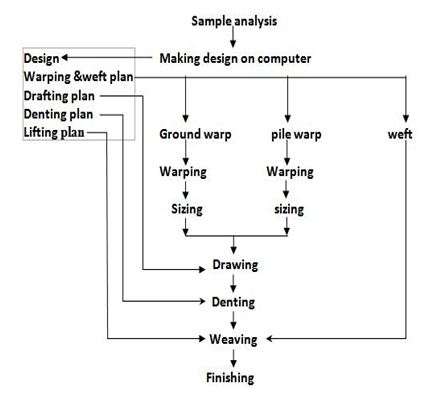

2.4 Sample analysis:

After getting the order sample R&D team analyze the sample and find out the all parameter (epi, ppi, total no of ends, total no of picks, weaving structure, weaving technique, yarn color, yarn count, types of yarn) of that sample

2.5 Making design on computer:

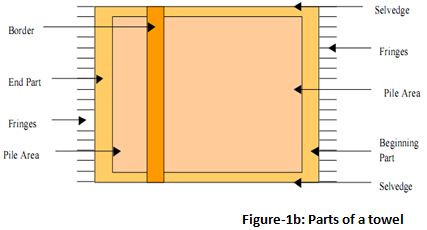

Figure-1b: Parts of a towel

Shabab Fabrics Ltd. has three special cad software for developing the design of the fabrics.

a. Textronics Design Dobby.

b. Textronics Design Jacquard.

c. Staubli pattern editor

Heald shaft capacity dobby loom’s of Shabab Fabrics Ltd. Is fourteen. So if the samples interlacement variation is up to 14 then that the design will develop in Design dobby software, if it is more than 14 then it will go for the design jacquard software.

3.Description of the Preparatory section

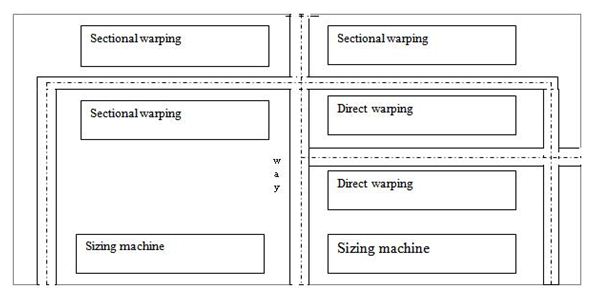

3.1 Layout preparatory section:

Figure 3: layout preparatory section

3.1 Warping:

There are two types of warping machine in Shabab Fabrics ltd.

a. direct warping

b. Sectional warping

4.Description of the weaving section

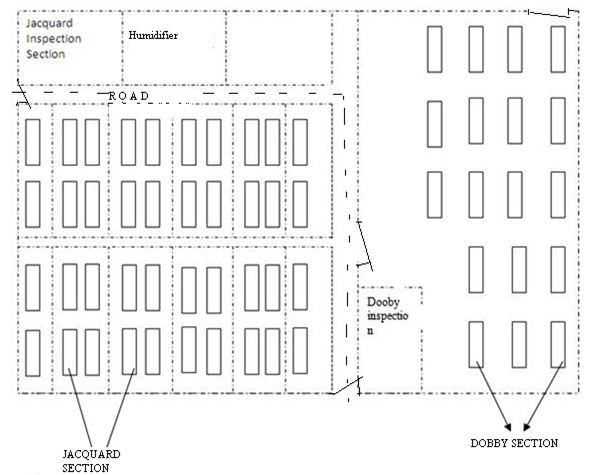

4.1 Layout of the weaving

section:

Figure 4: layout of the weaving floor

Figure 4: layout of the weaving floor

4.1 Machines of weaving section:

Sl no Functional name Description Quantity

01 Jacquard loom Sulzer Ruti Gripper terry loom

Sulzer Ruti G6100 B2700

Model :F6 JQG 1996 12

02 Jacquard loom Sulzer Ruti Gripper terry loom

Sulzer Ruti G6100 B2700

Model :F08SPG1 1989

07

03 Jacquard loom Sulzer Ruti Gripper terry loom

Sulzer Ruti G6100 B2700

Model :F08JG1 1989 06

04 Jacquard loom Sulzer Ruti Gripper terry loom

Sulzer Ruti G6100 B250/260

Model : P44SPG1 1988 13

05 Jacquard loom Sulzer Ruti Gripper terry loom

Sulzer Ruti G6100 B250/260

Model :FTJGI 1988 04

06 Jacquard loom Sulzer Ruti Gripper terry loom

Sulzer Ruti G6100 B270

model : F08SPg 1989 02

07 Jacquard loom Sulzer Ruti Gripper terry loom

Sulzer Ruti G6100 B270 f6

model :SPQGI 1996 01

08 Dobby Loom TPS(sultex) Gripper Terry Loom

290 cm working width with 4-6 color

Selector, with 16 shaft Staubli dobby 18

5. Power generation:

Steam System:

It is essential for textile industries to have a boiler system for heat exchange for the require ment of heat to different machine like, dyeing machine, tumble dryer, stenter, sizing, calendering, different finishing machine etc.

Fig: Cochran Boiler

6. Description of dyeing section

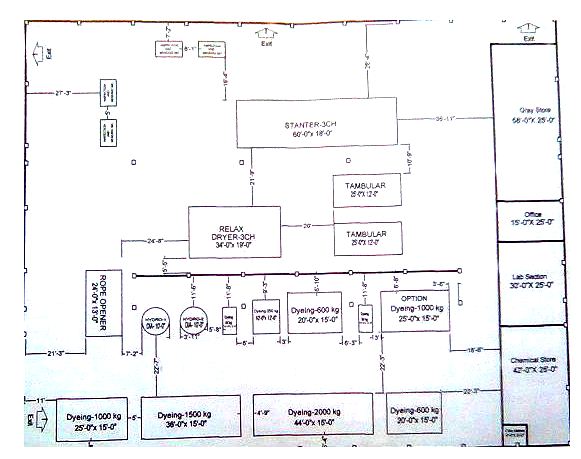

6.1 Layout of dyeing section:

Figure 5: lay out of dyeing section

6..2 Machines dyeing section:

| Sl no | Functional name | Description | Quantity |

| 01 | Water treatment plant | Water treatment plant | 01 |

| 02 | Tumbler | Tumbler Model: 2001 | 02 |

| 03 | Hydro Extractor | Santrafuj this Hydro Extractor, Modek;1988 | 01 |

| 04 | Hydro Extractor | Santrafuj this Hydro Extractor, Modek;2001 | 01 |

| 05 | Dyeing nem/c | 600/2 dilmener DMS 11 HT Jump Model-2006 Capacity: 600 kg | 02 |

| 06 | Dyeing M/C | KTM/H.T Rapid Machine 250-kg Type HT-E Model: 2009 Capacity: 250 kg | 01 |

| 07 | Sample dyeing mach | KTM/H.T Rapid Machine 25-kg Type HT-E Model: 2009 Capacity:25 kg | 2 |

| 08 | Dyeing machine | KTM/H.T Rapid Machine Type HT-E Model: 2009 Capacity: 1.5 ton Remarks: waiting for comissioning | 1 |

| 09 | Dyeing machine | KTM/H.T Rapid Machine 2ton Type HT-E Model: 2009 Capacity: 2 ton Remarks: waiting for comissioning | 1 |

| 09 | Stanter | Stanter | 01 |

| 10 | Rope Opener | Rope Opening Eltsmak Model-2006 | 01 |

6.3 Flow chart of dyeing-finishing after weaving.

7.Description of stitching section:

• Total 20 plain stitching m/c in this unit.

7.1 Description of machine:

BRAND NAME : JACK

MODEL NO. : JK(XUNCHI)/89900

COUNTRY OF ORIGIN : CHINA

MANUFACTURER : Jack industrial sweing m/c.

MAXIMUM SPEED : 5000 rpm

LOCK STITCH :

Mainly Lock stitch is use for towel hem and topsin Stitching.Some Description given below-

The lockstitch uses two threads, an upper and a lower. The upper thread runs from a spool kept on a spindle on top of or next to the machine, through a tension mechanism, a take-up arm, and finally through the hole in the needle. The lower thread is wound onto a bobbin, which is inserted into a case in the lower section of the machine. To make one stitch, the machine lowers the threaded needle through the cloth into the bobbin area, where a hook catches the upper thread at the point just after it goes through the needle. The hook mechanism carries the upper thread entirely around the bobbin case, so that it has made one wrap of the bobbin thread. Then the take-up arm pulls the excess upper thread ( from the bobbin area ) back to the top forming the lockstitch ideally in the center of the thickness of the material, the tension mechanism prevents the thread from being pulled from the spool side, the needle is pulled out of the cloth, and the feed dogs pull the cloth back one stitch length, the cycle is repeated as the machine turns mechanically .Lockstitch is so named because the two threads, upper and lower, “lock” together in the hole in the fabric which they pass through. The term “single needle stitching”, often found on dress shirt labels, refers to lockstitch, as opposed to chain stitch which unravels easily and is usually used on lower quality garments.

7.2Automatic cutting m/c

Schematric Diagram

Of Round Knife

BRAND NAME : Azimo

MODEL :#33

Country Of ORIGIN : Germany

7.3 Description:

1. AZİMO 333 cuts a towel cloth with any thickness, whithout considering the thickness of pile and the border.

2. Border controlled cloth directing system by referencing border of the cloth, it supplies the straight line’s flowing on the same line.

3. The sipral bendaged roller which is prepared specially, has cloth strength by the machine’s instigating.

4. The special pile guide system which is assembled to a knife, supplies a standart cutting by following the pile, whithout any mistake. The width of a guide is 50 mm.

5. The speed of cutting changes between 0 – 30 m/mins. And it can be changet by potentialneter.

6. The machine has the highest productivity and sensibility.

7. The body of the machine is dyed staticly and is very durable for strokes and rusting.

8. AZİMO 333 becouse its being controlled by PLC, the product is controlled by a computer is every stage. Besides, there is a whole electronic control in the machine.

9. AZİMO 333 tripple phased rigged motor knives are produced specially. This machine does not keep any dust on the thread does not wrapped around during the cutting. Owing to special protection for the knives that are designed against to accidents. There is no need to stop & pull out the machine in order to sharpen the knives.

10. Uncutted towels can be stocked in J-Box reservior. By this way, machine can work continuosly and this increases the productivity.

7.4 Automatic Stitching M/C

Brand name : Continuous Stitching Machine

Model : SCHEMALE DURATE 640

Year of construction : 2004

Country Of Origin : Germany

Voltage : 400v

Frequency : 50Hz

Air pressure : 6 Bar

7.5Descrption :

Max. Working width 160 cm (towel length)

Max. Working Length 100 cm (Seam length)

Feeding is carried out by the positioned and continuous placing the material onto the conveyor belt.conveyor belt speed max.approx.14 m/min.

All further working processes such as cutting of the fabric,label insertion and cross hemming are carried out automatically.

BRAND NAME : Long Tadonal Heming m/c

Country of Origin : Germany

7.6 Automatic Cutting M/C

BRAND NAME : azimo

MODEL : 444

ELECTRICAL INPUT : 50 Hz

WIDTH : 1460 mm

LENGTH : 1560 mm

Group A : It Helps the towel,which is to be cut,reach the process group after being stretched.

Group B : This is the process group in which the towel coming from the constant cylinder group goes through the cutting process, depending on the wdith cutting dimensions.

Group C : Operator platform designed to make the machine operation easier .

Cutting process :

1. Adjust the padel according to the width of the towel manually.

2. When the blade is pushed on to the padel, the towel will proceed depending on the value entred on the monitor.

3. The blade will start working when it interacts with the stainless sheet.

4. After the blade touches the stainless sheet in the cutting process,the towel placed between the cutting blade and dimond.

5. The air blade is moved alongside the width of the towel.

6. The cutting process of the machine is continued as much as the number entred on the monitor.

7.7 Semi Automatic Stitching m/c

BRAND NAME :SEMCONTINOUS HEM STITCHIN M/c

MODEL : SCHEMALE DURATE 614

COUNTRY OF ORIGIN : GERMANY

Descrption :

Max. Working width 160 cm (towel length)

Max. Working Length 100 cm (Seam length)

Feeding is carried out by hand onto the conveyor belt.conveyor belt speed max.approx.14 m/min.

All further working processes such as cutting of the fabric,label insertion and cross hemming are carried out automatically.

BRAND NAME : TAJIMA

MODEL : NE-02

COUNTRY OF ORIGIN : JAPAN

SPECIFICATION : Extra large sewing field(19.5 *14 Inch)

Uper and lower thread break detector.

Quick change over.

Automatic upper and lower thread trimming

Beam sensor safty

8.Quality Management system

Quality management system:

Independent

Quality standard

ISO 9000, OKO

flow diagram of online/in-process Quality control for each product:

Conclusion:

At the end of industrial training i can say that i have successfully copleted my industrial training at shabab fabrics ltd.every textile student should do their training attentively and regularly because it minimizes the gap between our theoritical and practical knowledge.after the completion of the training preiod i have secured practical knowledge about different production proces,.machinary maitanence industrial management and the practical environment of the industry ,that will help me to build my future.shabab fabrics ltd’s managemant help me lot about all mu quest.