Southwest Research Institute has created a new modular steel buttress dam system to address energy storage issues that are impeding the integration of renewable energy into the energy mix. The m-PresaTM modular steel buttress dam system allows for the rapid construction of paired reservoir systems for grid-scale energy storage and generation using closed-loop pumped storage hydropower (PSH), reducing dam construction costs by one-third and construction timelines by half.

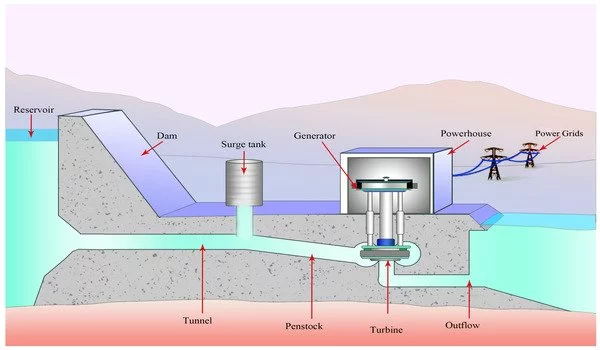

PSH is used in electric power systems to balance load. The method employs the gravitational potential energy of water, which is pumped from a lower-elevation reservoir to a higher-elevation reservoir with the pumps powered by low-cost, off-peak surplus electric power. During times of high demand, the stored water is returned to the lower reservoir, where it drives turbines to generate electricity.

Despite the fact that the pumping process consumes more energy than it generates, the system adds value by providing more electricity during peak demand, when electricity prices are highest, reducing the challenges associated with huge daily swings in intermittent, variable, and carbon-free renewable energy, such as solar and wind power.

We propose closed-loop pumped storage hydropower units by storing water in upper and lower reservoirs, impounded by buttress dams constructed from prefabricated structural steel modules.

Gordon Wittmeyer

“Pumped storage hydropower accounts for approximately 95 percent of all energy storage in the U.S., and modern PSH plants have a round-trip efficiency approaching 80-percent,” said Dr. Gordon Wittmeyer, a hydrologist in SwRI’s Chemistry and Chemical Engineering Division. “However, only one moderate-sized 40 MW PSH plant has been constructed in the past two decades in the U.S. Three factors stand in the way of rapidly deploying PSH: cost to construct, time to construct, and potential environmental impacts. The SwRI-developed m-Presa system addresses all three of these issues.”

Cost factors that continue to deter new investment in PSH include large capital costs – as much as $5,000 per kW installed capacity – and the lack of clear energy storage pricing signals. The m-Presa™ design could reduce construction costs to $1,500 per kW-installed capacity, making PSH competitive with other long-term energy storage modes.

The time it takes to build reservoirs is also a significant cost factor. A conventional PSH plant can often take ten years to site, design, build, and commission, at a time when private investors are seeing paybacks of ten years or less from subsidized solar and wind farms. PSH may be more appealing than other solutions for managing large daily swings in solar generation, such as non-sustainable gas peaking plants or shorter-lived battery energy storage systems, if the time between project initiation and revenue generation is reduced.

“We propose closed-loop pumped storage hydropower units by storing water in upper and lower reservoirs, impounded by buttress dams constructed from prefabricated structural steel modules,” Wittmeyer said. “These structural steel modules can be transported on standard-sized flatbed trailers to allow rapid modular construction of 10- to 40-foot-high buttress dams that can enclose a wide range of surface areas and water volumes.”

Another significant impediment to using PSH when impounding a natural waterway is the potential environmental impact of reservoir construction. Potential environmental impacts associated with closed-loop PSH can be reduced or avoided if the upper and lower reservoirs are created by building fully enclosed dams separate from natural streams or rivers.

“The m-Presa system uses strong, long-lived steel buttress dams to create water impoundments that can store hundreds to thousands of MWhs of energy to supply power during periods of peak demand and provide ancillary services for grid stability,” said Wittmeyer. “A PSH unit using the m-Presa system can be constructed in less than half the time needed for traditional PSH units that use earthen embankment or concrete dams to impound water.”