Boron nitride gives rise to compounds that can be either soft or hard, just as carbon makes up both the brittle core of a No. 2 pencil and the harder-than-steel diamond in a cutting tool. However, compared to carbon, far less is understood about the forms of boron nitride and how they react to changes in pressure and temperature.

Researchers from Rice University combined cubic boron nitride, which is second only to diamond in hardness, with hexagonal boron nitride, a soft variety also known as “white graphite,” and discovered that the resulting nanocomposite interacted with light and heat in unexpected ways that could be useful in next-generation microchips, quantum devices, and other applications of advanced technology.

“Hexagonal boron nitride is widely used in a variety of products, such as coatings, lubricants and cosmetics,” said Abhijit Biswas, a research scientist who is the lead author of a study about the research published in Nano Letters. “It’s quite soft and it is a great lubricant, and very lightweight. It’s also cheap and very stable at room temperature and under atmospheric pressure.”

“Cubic boron nitride is also a very interesting material, with properties that make it very promising for use in electronics. Unlike hexagonal boron nitride, it’s super hard it’s close to diamond in hardness, actually.”

In terms of many capabilities, the composite of these two seemingly incompatible materials performed better than its parent components.

“We found the composite had low thermal conductivity, which means it could serve as a heat-insulating material in electronic devices, for instance,” Biswas said. “The thermal and optical properties of the mixed material are very different from an average of the two boron nitride varieties.”

What is fascinating about this study is that it opens up possibilities to tailor boron nitride materials with the right amounts of hexagonal and cubic structures, thus enabling a broad range of tailored mechanical, thermal, electrical and optical properties in this material.

Pulickel Ajayan

Hanyu Zhu, one of the corresponding authors on the study, said he expected that “the optical property we measure called second harmonic generation would be small for this type of disordered material.”

“But it actually turns out to be quite large after heating, an order of magnitude more than both the individual material and the untreated mixture,” said Zhu, the William Marsh Rice Chair and assistant professor of materials science and nanoengineering.

He said the boron and nitrogen atoms in the composite displayed greater regularity and formed larger grains, where a grain designates the size of a group of atoms aligned coherently in a lattice.

“We were surprised to find that the cubic boron nitride grains grow instead of diminish in this material from the small grains in the unmixed starting compounds,” he said.

Theoretical predictions and experimental results yielded competing claims about which of the two boron nitride varieties was the more stable:

“Some theorists say that, at ambient conditions, cubic boron nitride is more stable,” Biswas said. “Experimentally, people have seen that hexagonal boron nitride is very stable. So if you ask someone which boron nitride phase is the most stable, they’ll likely say hexagonal boron nitride. What we’re seeing experimentally is the opposite of what people are saying theory-wise, and it’s still up for debate.”

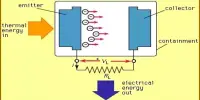

When the composite was subjected to a rapid, high-temperature technique known as spark plasma sintering, it transformed into hexagonal boron nitride.

Biswas said this confirmed theoretical predictions and helped paint a fuller picture of “which varieties of boron nitrides appear at what conditions.”

Additionally, the hexagonal boron nitride that was produced following this process was of higher quality than the one that was first used for the mixture.

“What we’ll be looking at next is whether the spark plasma sintering technique improves the quality of hexagonal boron nitride all on its own, or whether you need the composite to get that effect,” Biswas said.

“What is fascinating about this study is that it opens up possibilities to tailor boron nitride materials with the right amounts of hexagonal and cubic structures, thus enabling a broad range of tailored mechanical, thermal, electrical and optical properties in this material,” said Pulickel Ajayan, a corresponding author on the study and chair of Rice’s Department of Materials Science and Nanoengineering.

Ajayan is the Benjamin M. and Mary Greenwood Anderson Professor of Engineering and a professor of materials science and nanoengineering, chemistry, and chemical and biomolecular engineering.