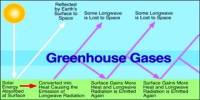

Plastics are adaptable and have desirable packaging properties such as flexibility, durability, and affordability. Plastic production has increased over the years, raising concerns about single-use and disposal. Because plastics are nonbiodegradable, they have been linked to negative health effects as a result of leaching chemicals from landfills and their accumulation in the natural and marine environment.

Plastics have many societal benefits and are widely used in our daily lives because they are lightweight, inexpensive, and adaptable. The production, processing, and disposal of plastics, on the other hand, pose a major global threat to the environment and human health. However, researchers have discovered a sustainable method for processing and reshaping a new type of hydroplastic polymer – ‘hydrosetting,’ which uses water under normal conditions.

An ideal solution would be the eco-friendly processing of reusable and recyclable plastics derived from plant-based raw materials. So far, the technological challenges have proven to be too daunting. However, researchers at the University of Göttingen have discovered a sustainable method – “hydrosetting,” which uses water under normal conditions – for processing and reshaping cellulose cinnamate, a new type of hydroplastic polymer (CCi). The findings were published in the journal Nature Sustainability.

Researchers have found a sustainable method – ‘hydrosetting’, which uses water at normal conditions – to process and reshape a new type of hydroplastic polymer.

Researchers from the University of Göttingen have succeeded in developing a new type of cellulose cinnamate, or CCi, by modifying a small portion of the chemistry of cellulose with the introduction of the ‘cinnamoyl’ group.

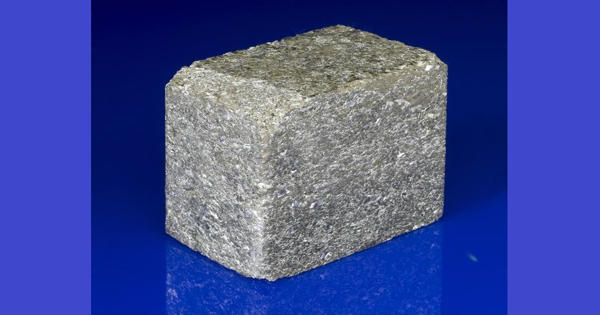

Plastics are polymers, which means that their molecular structure is made up of many similar units that are bonded together. Currently, most plastics are made with petrochemicals as raw materials, which are harmful to our environment both to extract and to dispose of. In contrast, cellulose, the main component of plant cell walls, is the most abundant natural polymer on the planet, providing an almost limitless supply of raw material.

The researchers succeeded in creating a specific CCi that is suitable for the formation of a new type of bioplastic with hydroplastic (ie soft and mouldable on contact with water) polymers by slightly modifying a very small portion of the chemistry of cellulose by introducing a “cinnamoyl” group.

This means that the plastic can be molded with water at normal temperatures and pressures. The hydrosetting method enabled the researchers to create a variety of shapes simply by immersing the bioplastic in water and allowing it to dry in the air.

This means that it can be molded with nothing more than water at normal temperature and pressure. The researchers were able to create a variety of shapes using this novel method, known as hydrosetting, by simply immersing the bioplastic in water and allowing it to dry in the air. The moulded shapes retained their stability over time and could be reshaped into a variety of 2D and 3D shapes. Although the plastic should not come into direct contact with water because it will lose its shape, it can hold water and be used in humid environments. When compared to commonly used plastics, the CCi bioplastics demonstrated superior mechanical properties.

“Our research provides a feasible method for designing other eco-friendly hydroplastics from renewable resources,” says University of Göttingen Professor Kai Zhang. “This should stimulate further research into other sustainable bioplastics with superior mechanical properties and new features.”

The hydrosetting process eliminates the need for expensive and complex machinery, as well as harsh processing conditions. This environmentally friendly method greatly simplifies the production of plastics, making their processing and recycling more cost-effective and sustainable. “This research offers tremendous potential for bioplastics like this to be applied in many different situations, such as biology, electronics, and medicine,” Zhang says, before adding, “In particular, the detrimental effects of plastics on the environment, which are harmful to all forms of life on Earth, would be minimized by reusing hydroplastics with their unique features.”