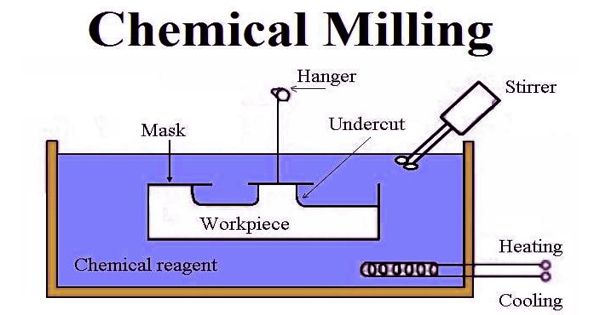

Chemical milling is the subtractive machining process using baths of temperature-regulated etching chemicals to remove material for producing the required shape. It is also known as industrial etching which is the subtractive manufacturing process of using baths of temperature-regulated etching chemicals to remove material to create an object with the desired shape. It is defined as the method of chemically corroding material to produce blind features like pockets, channels, etc.

Chemical milling is a highly accurate manufacturing process used to produce high-precision metal parts. It is a manufacturing method that is also being referred to as Photo etching, Electro-chemical Etching, among others.

It is mostly used on metals, though other materials are increasingly important. It also removes material from the entire surface of components for the purpose of weight reduction. It was developed from armor-decorating and printing etching processes developed during the Renaissance as alternatives to engraving on metal. During the Renaissance as alternative for etching on metal, it was developed from printing etching and armor-decorating processes. This method is extensively used on metals, although other different materials are gradually becoming more essential.

The chemical milling process is generally carried out in a series of five steps: cleaning, masking, scribing, etching, and demasking. At first, the workpiece surface is cleaned properly for removing the contaminants which could negatively impact the quality of the finished part. An improper cleaned surface could result non-uniform etching and poor adhesion of the maskant causing inaccurate final dimensions of workpiece surface. The workpiece surface must be remained free from grease, primer coatings, oils, markings, scale (oxidation), and any other foreign contaminants.

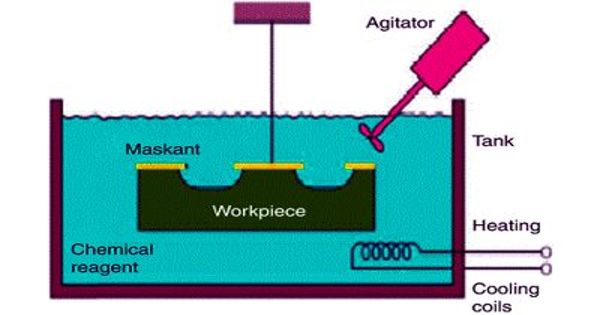

The process basically dips the cutting areas in a corrosive chemical known as an etchant, which etches with the material in the area to be cut and causes the solid material to be dissolved. The process essentially involves bathing the cutting areas in a corrosive chemical known as an etchant, which reacts with the material in the area to be cut and causes the solid material to be dissolved; inert substances known as maskants are used to protect specific areas of the material as resists. The effect of surface quality on strength led us to develop methods for polishing the surface, and it turned out that this polymer could be polished by chemical milling, a method long used by metallurgists in examining thin foils for electron microscopy, for example.

The etchant would react into the unexposed areas and the painted areas are to be protected from chemical reactions. This controlled etching in this manner allowed armor plate to be decorated as if with accurate engraving without the existence of formed burrs. It also protected the inevitability of the armor being softer than an engraving tool.

Information Source: