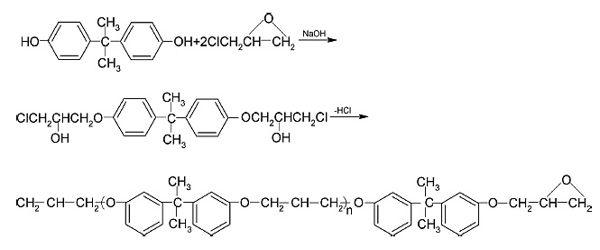

Epoxy refers to any of the basic components or cured end products of epoxy resins, as well as a colloquial name for the epoxide functional group. Epoxy resins, a flexible usually thermosetting resin made by copolymerization of an epoxide with another compound having two hydroxyl groups and used chiefly in coatings and adhesives. It is also known as polyepoxides, are a class of reactive prepolymers and polymers that contain epoxide groups.

Epoxy resin is the major type of structural adhesive and engineering adhesive used in the applications of human life and has high-performance bonding strength. Epoxy resins may be reacted (cross-linked) either with themselves through catalytic homopolymerization, or with a wide range of co-reactants including polyfunctional amines, acids (and acid anhydrides), phenols, alcohols, and thiols (usually called mercaptans). It can be used for metal, glass, and plastics. It can be fabricated as an adamantine or flexible, high optical transparent or opaque, and fast or slow setting.

Epoxies can be used for a range of applications. Using epoxy for adhesive applications is arguably one of the most popular uses. These co-reactants are often referred to as hardeners or curatives, and the cross-linking reaction is commonly referred to as curing. Generally, epoxy resin cured with heat will be more heat- and chemical-resistant than those cured at room temperature. They are considered the strongest adhesive available, and epoxy adhesives have found use in the automotive and aerospace industries.

Epoxy is a thermosetting polymer that possesses unique mechanical and resistance properties. The reaction of polyepoxides with themselves or with polyfunctional hardeners forms a thermosetting polymer, often with favorable mechanical properties and high thermal and chemical resistance. The term epoxy can be used for the cured end product or any of the basic components within epoxy resins. Epoxy resins are outstanding electrical insulators, which makes them useful components for the electronics industry.

Advantages:

- Strength: The polymeric structure of epoxies creates a remarkable strong bond and one that is waterproof and able to withstand high temperatures.

- Compatibility: Epoxy can work to bind a broad array of different materials while other common adhesives are more limited in their use.

- Speed: The curing time varies for epoxies, but for some fast-acting ones it can be under an hour for a functional cure.

Disadvantages

- Complicated Application: In many situations it is easier to reach for a bottle of wood glue or Super Glue, and the resulting bond will be sufficiently strong.

- Ventilated Spaces: Epoxy fumes are hazardous and you’ll want to limit their use to well ventilated spaces.

Epoxy is used in the construction of airplanes and cars, among other things. It has a wide range of applications, including metal coatings, use in electronics/electrical components/LEDs, high tension electrical insulators, paintbrush manufacturing, fiber-reinforced plastic materials, and adhesives for structural and other purposes. It is so sticky and so strong that it can hold together the parts of a boat or a bicycle, and keep the fin of a surfboard attached, even in the water.

Information Source: