Nickel silicides include several intermetallic compounds of nickel and silicon. It is an attractive alternative to the currently used silicides for the coming generations of deep submicron complementary metal-oxide-semiconductor (CMOS) devices.

Nickel silicides are important in microelectronics as they form at junctions of nickel and silicon. This silicide material has a resistivity, which is comparable to that of TiSi2 or CoSi2, but consumes less silicon for its formation. Additionally, thin layers of nickel silicides may have application in imparting surface resistance to nickel alloys. The silicide silicon interface is relatively planar and, unlike TiSi2, its resistivity does not change with the linewidth for narrow lines.

Compounds

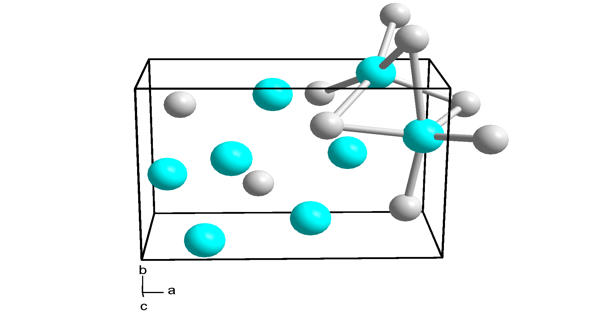

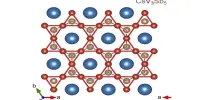

Nickel silicides include Ni3Si, Ni31Si12, Ni2Si, Ni3Si2, NiSi and NiSi2. Ni31Si12, Ni2Si, and NiSi have congruent melting points; the others form via a peritectic transformation. The silicides can be made via fusion or solid state reaction between the elements, diffusion at a junction of the two elements, and other methods including ion beam mixing.

Properties

Nickel silicides are generally chemically and thermally stable. They have low electrical resistivity; with NiSi 10.5–18 μΩ·cm, Ni2Si 24–30 μΩ·cm, NiSi2 34–50 μΩ·cm; nickel-rich silicides have higher resistivity rising to 90–150 μΩ·cm in Ni31Si12.

- Molecular Weight: 145.47

- Appearance: solid

- Melting Point: N/A

- Boiling Point: N/A

- Density: 7.40 g/cm3

- Solubility in H2O: N/A

- Monoisotopic Mass: 143.8480072

Uses

- Microelectronics

Nickel silicides are important in microelectronic devices – specific silicides are good conductors, with NiSi having a conductivity approaching that of elemental nickel. With silicon carbide as the semiconductor nickel reacts at elevated temperatures to form nickel silicides and carbon.

- Other

Nickel silicides have potential as coatings for nickel-based superalloys and stainless steel, due to their corrosion, oxidation, and wear resistance. NiSi has been investigated as a hydrogenation catalyst for unsaturated hydrocarbons. However, the thermal stability of NiSi is relatively poor at the currently used temperatures during process integration. Nickel silicide nanoparticles supported on silica support have been suggested as an alternative catalyst to widely used pyrophoric Raney nickel.

Information Source: