Pressure swing adsorption (PSA) is a process that occupies a large part in the unit operation for the purification and separation of gas mixtures. It is a technology used to separate some gas species from a mixture of gases under pressure according to the species’ molecular characteristics and affinity for an adsorbent material. It is an economic and reliable method for separating a wide range of process gases and bringing them to a very high purity level. It operates at near-ambient temperatures and differs significantly from cryogenic distillation techniques of gas separation.

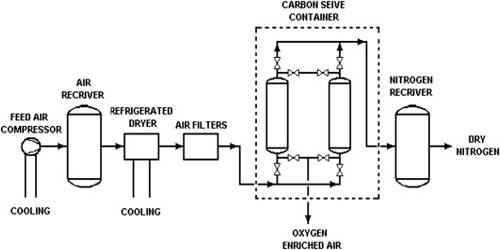

Process

Pressure swing adsorption processes utilize the fact that under high pressure, gases tend to be attracted to solid surfaces, or “adsorbed”. The higher the pressure, the more gas is adsorbed. When the pressure is reduced, the gas is released or desorbed. PSA for hydrogen purification works by pressurizing a vessel containing adsorbent. The process relies on the fact that different gasses adsorb at different pressures and temperatures

PSA processes can be used to separate gases in a mixture because different gases tend to be attracted to different solid surfaces more or less strongly. If a gas mixture such as air is passed under pressure through a vessel containing an adsorbent bed of zeolite that attracts nitrogen more strongly than oxygen, part or all of the nitrogen will stay in the bed, and the gas exiting the vessel will be richer in oxygen than the mixture entering. When the bed reaches the end of its capacity to adsorb nitrogen, it can be regenerated by reducing the pressure, thus releasing the adsorbed nitrogen. It is then ready for another cycle of producing oxygen-enriched air.

Pressure swing adsorption systems for oxygen production were first used in the 1970s. Since then, the technology has rapidly improved. This is the process used in medical oxygen concentrators used by emphysema patients and others requiring oxygen-enriched air for breathing.

The adsorption process is based on gas molecules binding to an absorbent material. Using two adsorbent vessels allows near-continuous production of the target gas. It also permits so-called pressure equalization, where the gas leaving the vessel being depressurized is used to partially pressurize the second vessel. This results in significant energy savings and is a common industrial practice. PSA units consist of multiple adsorber vessels containing one or more adsorbent layers.