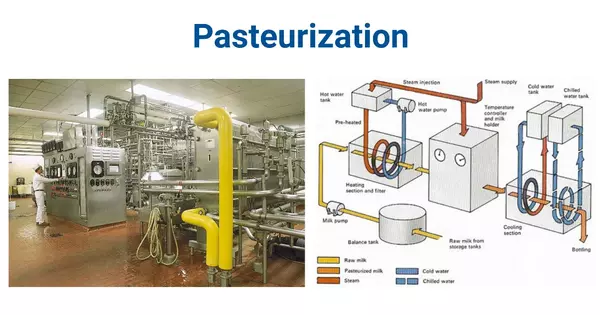

Pasteurization, also known as pasteurisation, is a food preservation process in which packaged and unpackaged foods (such as milk and fruit juices) are heated to less than 100 °C (212 °F) to kill pathogens and extend shelf life. It is a method of killing or deactivating harmful microorganisms such as bacteria, viruses, and fungi by heating food and beverages to a specific temperature for a predetermined period of time. The process is designed to kill or deactivate microorganisms and enzymes that contribute to food spoilage or disease risk, including vegetative bacteria, but the majority of bacterial spores survive.

The technique is named after the French microbiologist Louis Pasteur, whose research in the 1860s demonstrated that thermal processing could kill unwanted microorganisms in wine. Pasteurization also inactivates spoilage enzymes. Pasteurization is now widely used in the dairy industry and other food processing industries to preserve food and ensure food safety.

Pasteurization’s primary goal is to make treated products safer to consume by reducing the number of pathogenic microorganisms that may be present. It aids in the prevention of foodborne illnesses and increases the shelf life of perishable items. Pasteurization is widely used for a wide range of foods and beverages, including milk, fruit juices, beer, wine, and some canned goods.

There are two main methods of pasteurization:

- High-Temperature Short-Time (HTST) pasteurization: This method involves heating the product to a high temperature, typically around 72 degrees Celsius (161 degrees Fahrenheit), for a short period of time, usually around 15-20 seconds. HTST pasteurization is commonly used for milk and fruit juices.

- Low-Temperature Long-Time (LTLT) pasteurization: This method involves heating the product to a lower temperature, typically around 63 degrees Celsius (145 degrees Fahrenheit), for a longer period of time, usually around 30 minutes. LTLT pasteurization is commonly used for certain alcoholic beverages and some canned foods.

Pasteurization typically entails heating the product to a temperature of 60 to 85 degrees Celsius (140-185 degrees Fahrenheit) for a set period of time. The precise time and temperature are determined by the product being treated as well as the desired level of microbial reduction. In general, the goal is to strike a balance between eliminating harmful pathogens and preserving the product’s quality and taste.