Advances in materials science are frequently preceding the emergence of new technology. Since the material’s discovery, the advancement of diamond technologies has demonstrated this. For centuries, the allure of diamond as a gemstone and its use as a tool due to its hardness has encouraged research on technical applications.

Quantum Brilliance, an Australian National University (ANU) venture-backed quantum computing startup, will install the world’s first diamond quantum accelerator at the Pawsey Supercomputing Centre. Two research breakthroughs are on the verge of hastening the development of synthetic diamond-based quantum technology.

Diamonds are a girl’s best friend, as Marilyn Monroe famously sang, but they are also a favorite among quantum scientists, with two new research breakthroughs poised to accelerate the development of synthetic diamond-based quantum technology, improve scalability, and dramatically reduce manufacturing costs.

While silicon has traditionally been used in computer and mobile phone hardware, diamond has unique properties that make it especially useful as a foundation for emerging quantum technologies such as quantum supercomputers, secure communications, and sensors.

However there are two key problems; cost, and difficulty in fabricating the single crystal diamond layer, which is smaller than one millionth of a metre.

Two research breakthroughs are poised to accelerate the development of synthetic diamond-based quantum technology.

Diamonds are a girl’s best friend, as Marilyn Monroe famously sang, but they are also a favorite among quantum scientists, with two new research breakthroughs poised to accelerate the development of synthetic diamond-based quantum technology, improve scalability, and dramatically reduce manufacturing costs.

While silicon has traditionally been used in computer and mobile phone hardware, diamond has unique properties that make it especially useful as a foundation for emerging quantum technologies such as quantum supercomputers, secure communications, and sensors.

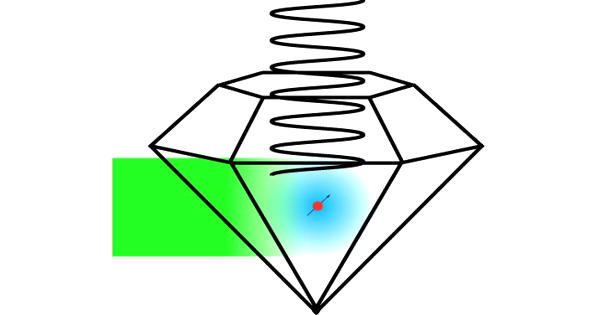

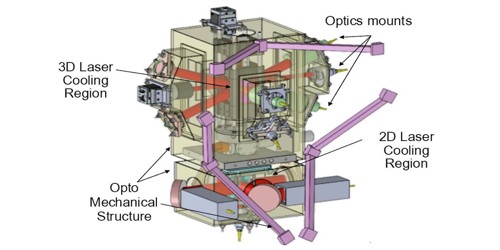

Quantum Brilliance uses synthetic diamonds to create quantum accelerators that, unlike mainframe quantum computers, do not require near absolute zero temperatures or complex laser systems to operate. Quantum Brilliance is one of only a few companies in the world that can provide market-ready quantum computing systems for customers to use on-site.

To overcome the “etching” problem, the researchers devised a new hard masking method that patterns the diamond nanostructure with a thin metallic tungsten layer, allowing the creation of one-dimensional photonic crystal cavities.

“The use of tungsten as a hard mask addresses a number of issues associated with diamond fabrication. It functions as a uniform restraining conductive layer, increasing the viability of electron beam lithography at nanoscale resolution “Blake Regan, a UTS Ph.D. candidate, is the lead author of the paper published in Nanoscale.

To the best of our knowledge, we provide the first evidence of the bottom-up growth of a single crystal diamond structure from a polycrystalline material – similar to growing flowers from seed.

“It also enables the post-fabrication transfer of diamond devices onto the desired substrate under ambient conditions. Furthermore, the process can be automated further to create modular components for diamond-based quantum photonic circuitry “He stated.

The tungsten layer is 30nm wide – about 10,000 times thinner than a human hair – but it allowed for a diamond etch of more than 300nm, a record selectivity for diamond processing. Another advantage is that the removal of the tungsten mask does not necessitate the use of hydrofluoric acid, one of the most dangerous acids currently in use, which improves the safety and accessibility of the diamond nanofabrication process.

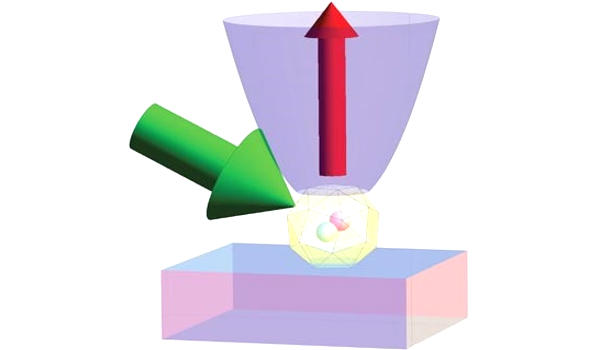

To address the cost issue and improve scalability, the team devised an innovative method for growing single crystal diamond photonic structures with embedded quantum defects from a polycrystalline substrate.

“Our process relies on a lower-cost large polycrystalline diamond, which is available as large wafers, as opposed to the traditionally used high-quality single crystal diamond, which is limited to a few mm2,” said UTS Ph.D. candidate Milad Nonahal, the study’s lead author in Advanced Quantum Technologies.

“To the best of our knowledge, we provide the first evidence of the bottom-up growth of a single crystal diamond structure from a polycrystalline material – similar to growing flowers from seed,” he added.

“Our method eliminates the need for expensive diamond materials and ion implantation, which is critical to accelerating the commercialization of diamond quantum hardware,” said UTS Dr. Mehran Kianinia, a senior author on the second study.