An organic light-emitting diode (OLED), also known as an organic electroluminescent (organic EL) diode, is a light-emitting diode (LED) in which the emissive electroluminescent layer is a film of organic compound that produces light in response to an electric current. They are a sort of solid-state lighting technology that has grown in prominence in recent years. OLEDs are a form of light-emitting diode (LED) in which the emissive electroluminescent layer is made of organic molecules.

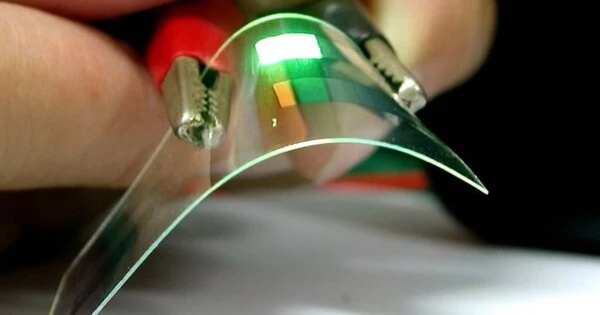

This organic layer is sandwiched between two electrodes, one of which is normally transparent. OLEDs are used to make digital displays in devices such as television screens, computer monitors, and portable systems such as smartphones and handheld game consoles. A major area of research is the development of white OLED devices for use in solid-state lighting applications.

There are two types of OLEDs: those that use tiny molecules and those that use polymers. When mobile ions are added to an OLED, a light-emitting electrochemical cell (LEC) is formed with a somewhat different mode of operation. A passive-matrix (PMOLED) or active-matrix (AMOLED) control method can be used to power an OLED display.

PMOLED control employs a thin-film transistor (TFT) backplane to directly access and switch each individual pixel on or off, allowing for better resolution and bigger display sizes. AMOLED control uses a thin-film transistor (TFT) backplane to directly access and switch each individual pixel on or off, allowing for higher resolution and larger display sizes.

Here are some key characteristics and features of OLEDs:

- Organic Materials: When an electric current is applied to organic compounds, they emit light. Carbon-based compounds and polymers are the most common organic materials. The organic layers are sandwiched between two electrodes, often a reflecting or transparent anode and a transparent cathode.

- Thin and Flexible: OLEDs are often extremely thin and flexible. As a result, they are appropriate for a variety of applications, including curved and foldable displays. Because OLEDs may be employed in flexible and rollable displays, they are perfect for smartphones, tablets, and wearable technologies.

- Self-Emitting: Each pixel in an OLED display produces its own light. In contrast, typical LCD (Liquid Crystal Display) technology necessitates a separate backlight. Because each pixel can be switched on or off separately, OLEDs provide higher contrast ratios and increased energy efficiency.

- High Contrast and Color Quality: In general, OLED screens have higher contrast ratios and better color accuracy than LCD displays. This produces images that are colorful and clear, with deep blacks, which is very crucial for applications such as televisions and smartphones.

- Fast Response Time: OLEDs have a fast response time, which is advantageous for applications requiring rapid refresh rates, such as gaming and virtual reality.

- Wide Viewing Angles: OLED displays have excellent viewing angles, meaning that the quality of the display is maintained even when viewed from different angles. This is important for large-screen TVs and displays that are meant to be viewed by multiple people simultaneously.

- Energy Efficiency: OLEDs can be energy-efficient because they only consume power when emitting light. In contrast, LCDs require a constant backlight, which can consume power even when displaying dark content.

Challenges

Smartphones, tablets, televisions, computer monitors, vehicle displays, and lighting all make extensive use of OLED technology. The propensity for organic materials to degrade with time, resulting in picture retention (burn-in) and shortened lifespan, is one of the problems of OLED technology. However, developments in materials and manufacturing techniques have enhanced OLED display endurance.