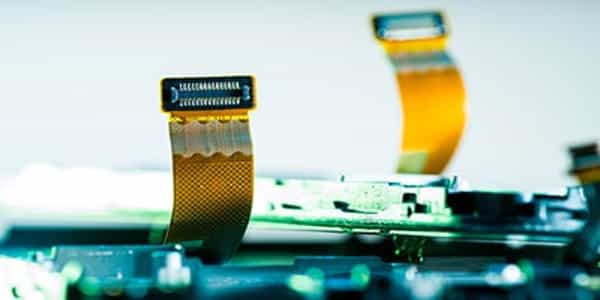

Flex circuits are a cutting-edge approach to total electronics packaging. They fill a void between standard printed circuit boards and round wire, absorbing many of each’s uses and benefits. In essence, flex circuits provide unrestricted packaging geometry while retaining the precision density and repeatability of printed circuits. Because they only fit in one way, these circuits make assembly easier. When compared to traditional wiring bundles, manufacturing time and error rates are reduced. Total installed costs are lower, especially when producing in large quantities.

UV light is used by researchers to tune circuit performance with a photoreactive polymer based on controlled changes in the chemical structure, which could lead to the development of wearable electronics and medical sensors. By illuminating an organic polymer with ultraviolet light, they were able to create flexible integrated circuits that were precisely tuned. This research could lead to the incorporation of low-cost electronics into wearable sensors or computers.

Researchers from Osaka University’s SANKEN (The Institute of Scientific and Industrial Research) and JOANNEUM RESEARCH (Weiz, Austria) demonstrated how exposing an organic polymer to ultraviolet light can precisely modify its electronic properties. This research could aid in the commercialization of flexible electronics for real-time healthcare monitoring and data processing.

Researchers created flexible integrated circuits precisely tuned by illuminating an organic polymer with ultraviolet light. This work may allow for inexpensive electronics to be incorporated into wearable sensors or computers.

While the integrated circuits inside your smartphone are impressive, they lack a few key features. Because silicon is used in electronics, they are very rigid, both in the literal sense of being inflexible and in the chemical sense of having chemical properties that are difficult to change. Newer devices, such as OLED displays, are made from carbon-based organic molecules with chemical properties that scientists can tune to produce the most efficient circuits.

However, controlling the characteristics of organic transistors usually requires the integration of complex structures made of various materials.

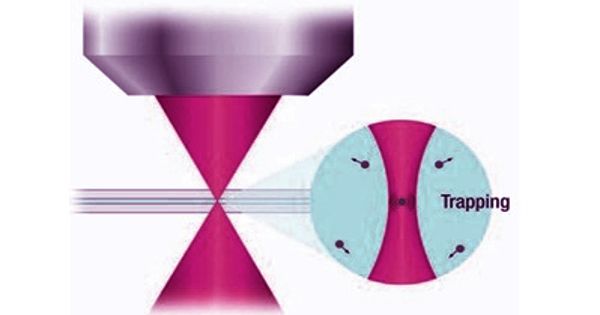

Now, a team of researchers led by Osaka University has used UV light to precisely change the chemical structure of PNDPE, a dielectric polymer. The light breaks specific polymer bonds, which can then rearrange into new versions or form crosslinks between strands. The longer the light is turned on, the more the polymer changes. The UV light is applied to only the desired areas using a shadow mask, tuning the circuit behavior. Using a single material, this method can pattern transistors with the desired threshold voltage and high spatial resolution.

“We were able to control the characteristics of organic integrated circuits by using persistent light-induced changes in the molecular structure itself,” study co-author Takafumi Uemura explains.

Flex circuits can be shaped to fit into spaces that no other design can. They are a cross between standard printed circuit boards and round wire, combining the advantages of both. In essence, flex circuits provide unrestricted packaging geometry while retaining the precision density and repeatability of printed circuits. Flex circuits not only fit into small spaces in the final application, but they are also much lighter than equivalent wiring harnesses. Flexible electronic assemblies can be made with the same components as rigid printed circuit boards, allowing the board to conform to a desired shape or flex while in use.

From medicine bottles to safety vests, we may see smart versions of almost everything in the future. “Meeting the computational demands of ‘the Internet of Things’ will almost certainly necessitate flexible electronic solutions,” says senior author Tsuyoshi Sekitani. This technology, in particular, can be used to develop manufacturing methods for ultra-lightweight wearable healthcare devices.

In the world of electronics, the adage “necessity is the mother of all inventions” is especially true when it comes to the invention, evolution, and development of flexible circuits in all types of electrical and electronic devices. Although it was developed around two decades ago, flexible circuits have only recently come of age as an interconnection technology. A flexible circuit is a pattern of conductors formed on a bendable film, typically polymers, that serves as an insulating base material. An insulating cover layer is applied to the top. A flexible circuit is similar to a rigid printed circuit board. In short, a flexible circuit is “a patterned arrangement of printed wiring utilizing flexible base material with or without flexible cover layers.”