Epyllion Group started its journey as a house of Readymade Garments (RMG) engaged in manufacturing and exporting of Knit Apparels since 1994 and has been considered today as one of the biggest conglomerates with substantial establishment of its backward linkage of all kinds of knit garments, textile, wet processing & garments accessories. Epylllion textile Limited is engaged in processing raw fabric to finished products and exports these products to different countries. Its factory is situated in Gazipur, Dhaka and head office is in Gulsan link road, Dhaka. I worked in the factory and paid occasional visits to the head office in order to cope up with the production process. I worked with almost all the departments; especially in Accounts and Finance Department, Knitting, Dyeing, Finishing department. My basic responsibilities is data reconciliation and find out process loss which increase the income statement of this company. This paper will aim to find out the production process, business, cycle. strength, weakness. threat, opportunities of Epyllion textile limited. The significance of this study is that now a particular research gap will be filled up and it will indicate if any further related research is needed or not. I have tried my best to complete this research but there are some limitations. I expect that those unintentional mistakes should be overlooked.

Introduction:

As it stands today, Epyllion Group became the name of lifestyle of its personnel, suppliers & buyers. For the greater commitment & care ‐ Epyllion Group always plays a significant role in its every activity by protecting environment and has earned an iconic image among the green corporate houses. These achievements of ours prevailing due to the personnel of the Epyllion Group are placed at their right positions according to their caliber and inspiration.

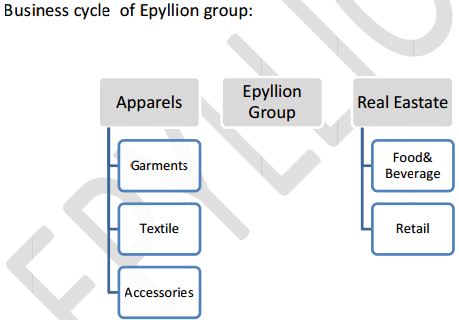

Overview of the Epyllion group:

Epyllion Group started its journey as a house of Readymade Garments (RMG) engaged in manufacturing and exporting of Knit Apparels since 1994 and has been considered today as one of the biggest conglomerates with substantial establishment of its backward linkage of all kinds of knit garments, textile, wet processing & garments accessories. It has the state of art vertically integrated garments manufacturing facility which ensures one stop service to the buyers. Beginning only with 2 sewing lines and total of 200 work force at Mirpur, Dhaka. Epyllion Group has new swelled up with 13500 work forces with 92 sewing line in several location of Dhaka and Gazipur. We have established ourselves as an important garments manufacturer for a number of renowned brand apparels of Europe, USA, Asia .

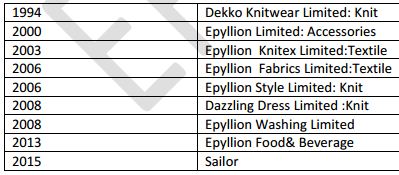

Establishment in different Business Units:

Main Body of this report

Objectives of the study:

By doing this project I have understood the business strategy of Epyllion Textiles Ltd. I will have a good understanding about the management and production process of the organization. I have chosen this topic because our economy is very much dependent on textile industry and Epyllion is one of the largest conglomerates in our textile industry. I want to know their business process and how to reduce production cost which will help me to implement in future.

Vision

Our vision is to become a window through which all our interacting parties can see and feel their prospect and dream about their success. Epyllion will become a lifestyle towards its employees, suppliers, buyers and above all shall become a role model of a green corporate house which will be regarded as an icon brand in the country.

Mission

Epyllion will be known as an entity whose main driven force is its human resources. With such a motivated, high skilled and professional workforce, Epyllion has started marching towards its glory of success which is not the profit but to enjoy the joy of life.

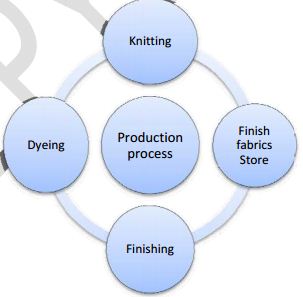

The production process of Textile division:

The Epyllion Textile Division is a truly integrated undertaking. The Textile Division has the capability to offer a complete product range for the export and domestic textile markets. The goal of the Textile Division is to become the preferred partner for sourcing high quality fabrics and clothing from Bangladesh. With highly advanced technology and an emphasis on developing local human resources, the Textile Division has the potential to make an important contribution to the nation’s growing readymade garments export sector. Epyllion textile division production process is given bellow:

Knitting

Knitting by machine is done in two different ways; warp and weft. Weft knitting (as seen in the pictures) is similar in method to hand knitting with stitches all connected to each other horizontally. Various weft machines can be configured to produce textiles from a single spool of yarn or multiple spools depending on the size of the rnach:ne cylinder (where the needles are bedded). In a warp knit there are many pieces of yarn and there are vertical chains, zigzagged together by crossing the yarn. Epyllion knitting department receive gray yarn then make gray fabrics and delivery to batch preparation.

Dyeing

Finally, cotton is an absorbent fiber which responds readily to coloration processes. Dyeing, for instance, is commonly carried out with an anionic direct dye by completely immersing the fabric (or yarn) in an aqueous dye bath according to a prescribed procedure. For improved fastness to washing, rubbing and light, other dyes such as vats and reactive are commonly used. These require more complex chemistry during processing and are thus more expensive to apply. Dyeing received fabrics and send different Knowles according to batch ,after dyeing fabrics delivery to finishing department.

Finishing

The woven cotton fabric in its loom-state, not only contains impurities, including warp size, but requires further treatment in order to develop its full textile potential. Furthermore, it may receive considerable added value by applying one or more finishing processes.

Production facilities:

Laboratory

To support the factory a well equipped laboratory has been established with required testing. The lab has modern equipment like data color processor (USA), Steamer, Light Fastness tester, Tear & Tensile tester, Crocking & Perspiration tester etc.

Uninterrupted power supply

A full time uninterrupted gas based power generator is supplying 3.5 megawatt power to feed the whole production. This makes possible to run the industry round the clock and keep the modern computerized equipment trouble free.

Water Softening & Effluent Treatment

To ensure quality dyeing & finishing Epyllion makes sure of supplying soft water as per requirement for which water softening plant is in place. Epyllion Group always looks to the eco friendly environment which is a prime requirement for human health. An Effluent Treatment Plant is in operation to treat the effluents and discharge clear water to the canal.

SWOT ANALYSIS:

Strengths:

ISO 9001‐2000:

BGMEA&BKMEA Award, HSBC Export Excellence Award.

Epyllion textile is certified under ISO 9001‐2000 and so it meets the requirement of international standard and has a value in the mind of concern people.

- Strong Security System

Epyllion textile limited has a greater security system. There are different hidden security cameras which capture the all moments

- Quality Assurance (Not Quality Control)

In Epyllion, all of us culture the mindset of positive but inquisitive attitude even for our day to day work. Since qualities are not necessary quality innate, to establish these kind of mindset we often reward outstanding performances and achievements. We have spared some of our resources for the clients to inspect our goods, working procedure and environment, because we belief in customer driven marketing in order to be effective. Our customers are our prime focus, because through them we reap the rewards.

- Good Compliance

Epyllion Textile Limited compliance is very good that is why some days ago several counties ambassador &BGMEA group visited in our factory.

- Highly qualified and skilled management

The management of Epyllion is skilled they have hired the foreign graduate people in their management and also experienced people from all over the country.

Weaknesses:

- Old model Machineries

There are some machinery that are old model for this sometime not to maintain lead time .

- Knit based setup

Epyllion textile only produce knit based product, woven based product absent so that there are deprived from huge profit.

- Less promotional activities

The advertising and promotional cost of the Epyllion textile is very low it can take advantage for more turnouts.

- Absence of Spinning Plant:

Most of the big Garments industries that are well‐established have their own Spinning Plant. As a result they can sell their product more cheaply but Epyllion Knitwear Limited doesn’t have any Spinning Plant. For that reason their cost of production is high.

Opportunity:

- Organization can expand product lines

Currently the Epyllion not dealing in spinning they can expand their product line by producing spinning mill. They have plants and the extra cost for the production will be low for Epyllion. And they also have better market repute.

- Organization can reduce the cost by proper utilization of resources

If the cost of different matters which is not utilizing properly is controlled by the Epyllion management they can produce more in a few costs. It has to develop a further systematic process for controlling and managing resources.

- Organization can hire more well‐educated and experienced person

They can take advantages by hiring more skilled people and they should hire young, fresh and energetic staff for their betterment.

Threats:

- Buyer needs demands changes

Because of the research and development the design and the product of Epyllion is just satisfactory as compare to competitors in the globally and they are not fulfilling the demand of customer

- Political instability

Political instability effects the Epyllion because of the quota system the company can be restrict by the government to export

- Changed of government policies

Government policies are changing day to day so it is a threat for the Epyllion to survive in such a changeable situation

- Globally Economic instability

Because of the economic instability the Epyllion affected a lot. Dumping system which is rising on daily basis in the world can create many problems for the company and any uncertainty in the world like 9/11 may affect also the overall export

CSR Practice

CSR is a sustainable way of business management to execute company’s commitment and responsibility towards the people (Employee and community) ,planet (natural environment) and the profit (economic development).

Our CSR practice

- Epyllion group contributed 1 million BDT on 30 April 2013 to BGMEA as an aid for the victims of savar tragedy

- Epyllion group organized an eye camp and free medicine services for the workers and staffs of Dhaka zone business units on 28 August,2013.

- Epyllion group organized an eye camp and free medicine services for the workers and staffs of Textile Division ,Gazipur zone on 25 september,2013.

- A vitamin A campaign was held in epyllion style limited collaborated with our buyer. Children from 6 months to five years received vitamin A capsule from this campaign.

- Free coaching center in Narayanganj

- Renovated Rasulpur south government primary school.

- Epyllion group extended its hand to assistant the victim of extreme winter every year with winter cloth and blanket. In 2012 to 2014, more than 8500 pcs of winter wear and blankets are distributed among unprivileged person in Rangpur, Nilphamari, Kurigram and Faridpur.

- Epyllion group provided sponsorship to Earth Club environmental beneficiary project 2014,where 1000 potted plants provided among the faculty members North South University.

Recommendation:

From the analyses and findings interpreted above, I would like to recommend the following factors to be taken seriously by Epyllion management.

* Epyllion should increase their loom efficiency and install higher quality foreign machineries in order to avoid different types of fabric fault as well as avoid compensations, which incurs huge amount of losses sometimes.

* In order to avoid mismatch between samples and bulk, Epyllion should install fully automated computerized software and machineries because these problems usually arise from errors in manually input data and confusions from those. It is sometimes seen the pantone numbers are in correct ,sample numbers are incorrect in the labels. So, they should work seriously on this issue.

*Many more looms should be installed in order to avoid minimize the lead time for production. Otherwise the regular buyers will get delivery on time and local irregular buyers will not.

Ultimately they will lose interest in Epyllion and in future if there’s any scarcity of foreign buyers and orders at Epyllion, those dissatisfied local buyers will not place orders either.

* Efficiency should be maximized by employing more professional management personnel so that fabric price can be reduced because the yarn prices are increasing on a weekly basis now.

* In Audit Department MIS should be improved because this department do not use update software.

Conclusion:

From the above stated analysis, it can be said that product quality of Epyllion Textiles Ltd. Plays most significant rule for customer satisfaction. In addition to this, Good co-operation of Epyllion and their verities of product also play crucial rule for customer satisfaction.

Furthermore, to some extent buyers become satisfied when their requirements are fulfilled. Moreover, Buyers also become satisfied when they get good co-operation from Epyllion Textiles Ltd.

In order to avoid mismatch between samples and bulk, Epyllion should install fully automated computerized software and machineries because these problems usually arise from errors in manually input data and confusions from those.eat Epyllion fabrics industry.

Finally, I can conclude with saying that the product quality of Epyllion is the main reason for its customer satisfaction. Over here, product quality doesn’t mean the fabric quality only. It contains the over product, price, promotion, delivery, service, and commitment quality of Epyllion and its human resources then Auditing process reduce production cost which develop the company income statement.