Main purpose of this report is to analysis Export of Sweater from Bangladesh, here focus on Evance Accessories Limited. Other objectives are analysis the production process and analysis the environmentally health safety requirement perform by the Evance Accessories Ltd. Report also focus on analysis the product offers by this company and analysis the export procedures of the Evance Accessories Limited.

Introduction

Evance Accessories Ltd is a manufacturer/exporters and buying agent of Garments having good linkage program with garments industries to support import program from Bangladesh.

The newly sweater industry emerged from Evance Group of companies in the year 1998 as one of the best quality sweater manufacturers. Apart from sweater manufacturing business we run a garment buying & trading house.

The company is in a position to open Back to Back L/C for import of yarn and raw materials within a couple of days form the date of receipt of Master L/C for execution of the Export orders.

So far we have been working with different foreign buyers of USA, Italy, France, Germany, UK, Holland & Denmark to feed back our own manufacturing unit Evance Accessories Ltd and planning to split orders to our associate industries.

The first part of the report is introduction of the report, that’s consists of background of the study, objective, scope of the study, methodology, limitation and repot preview.

The author was assigned to asses the Export of sweater from Bangladesh of Evance in this report. Under the second part I discussed about the Overview of the Company. Then I have done Operating Procedures of Evance Accessories Ltd. Then I have done Marketing Strategy of Evance Accessories Ltd. And final part of this report including with recommendation, conclusion and Reference.

Evance Accessories Ltd intend to serve their customers worldwide with quality, sincerity, goodwill & excellence in gaining name and fame of the company with ultimate goal of making it to a conglomerate. The products of the project are extremely well received owing their super quality reasonable prices & maintenance of delivery schedule.

Garments Industry in Bangladesh:

At p resent Garment is the main industry of Bangladesh now. This sector have developed here rapidly because of it is a labour intensive industry, ordinary technology, cheap labour and small capital. Before liberation in 1970, in Bangladesh there was only one garment factory. In 1977, the number rose to 8. In 1984, the number was 587. In 1998, the number stood at 2650 and now the number of garments in Bangladesh is 3300.In Bangladesh garment factories are situated in Dhaka, Chitagong, Narayangong, Savar and Tongi-Gazipur. The Number of Garment workers in Bangladesh is 1.6 million. Number of woman workers is 1.320.000 and men 280.000.Seventy Six percent of total export of Bangladesh is garment oriented. Mainly Bangladeshi garments products are exported to the USA, Canada, and European Union and Carribean countries. Recently Bangladesh started export to Japan, Australia and some other countries in small scale. Bangladesh exports 63 items of garments products. Main raw materials of garments — mainly fabrics come from other countries. Bangladesh – the country of world famous muslin fabric and the Great Royal Bengal Tiger has now emerged as a child labour free apparel giant in the world textile and apparel market. The country exports its apparel products worth nearly 5 billion US$ per year to the USA, EU, Canada and other countries of the world. At present the country is the 6th largest apparel supplier to the USA and EU countries. The major products are Knit and Woven Shirts and Blouses, Trousers, Skirts, Shorts, Jackets, Sweaters, Sportswear’s and many more casual and fashion apparels.

Objective:

- To analysis Evance Accessories Ltd. and its operation

- To analysis the production process of the Evance Accessories Ltd.

- To analysis the environmentally health safety requirement perform by the Evance Accessories Ltd.

- To analysis the product offers by the Evance Accessories Ltd.

- To analysis the export procedures of the Evance Accessories Ltd.

Methodology of the Study:

The study has conducted on two sources of data:

(a) Primary Sources:

Formal and informal discussion with marketing & merchandising manage Formal questionnaire to commercial & merchandising, administration, account department & General Manager of Evance Accessories Ltd. Questionnaire Survey Telephone Survey Informal talks with involves parties.

(b) Secondary Sources:

Internal sources Export volume report, Sales record, Evance profile, Documents, Newspaper article, Website, BGMEA, FedEx, Transportation agency. By the communicate with the officers of Evance Accessories Ltd and I have got the idea about the position of Evance among in the garments industries, their target buyer, products, existing problems and prospect of this sector also prospect of Evance.

Company History:

Evance Accessories Ltd is a manufacturer/exporters and buying agent of Garments having good linkage program with garments industries to support import program from Bangladesh. Evance Accessories Limited emerged from Evance Group of companies in the year 1998 as one of the best quality sweater manufacturers. Evance Accessories Limited working as a different Garments items, mainly zipper, button, main label, size label ,care label, hang tag, price tag, poly, blister& carton and this company produce other mainly items of sweater, and well equipped with skilled and professional team members with commitment to execute big volume orders of the valued buyers.. The company is in a position to open Back to Back L/C for import of yarn and raw materials within a couple of days form the date of receipt of Master L/C for execution of the Export orders.

Company objectives:

We intend to serve our customers worldwide with sincerity, goodwill & excellence in gaining name and fame of the company with ultimate goal of making it to a conglomerate. And with our continued and hardworking efforts in the maintaining standard quality of the finished garments our perfect quality checking methods directly responsible to the management will certainly meet the customer’s satisfaction.

Maintaining 100% fine quality, strict quality control at every stage of production, responding fast to constantly changing demands. Our ultimate goal to make Evance as one of the best sweater manufacturers in Bangladesh.

Name of the associated companies of Evance Group is:

- Evance Accessories Ltd.

- Evance Textiles Ltd

- Evance Garments

- Evance Dyeing

- Evance Button

- Evance Label

- Etafil Threet

Operational Process:

Process of materials collection:

After get the order from buyer then Marketing &Merchandising section communicate with the Dying factory& Accessories supplier. And Marketing &Merchandising manager or Merchandiser consumption of Yarn as per buyer order. Then order to Dyeing factory for Lab-dips development. Here order to those Dying factories which provide the lower cost and better quality& due time delivery. Before Lab-dips order Merchandiser must collect original sample of Yarn / Color swatch / Panton.no from buyer. And given some original swatch to dyeing factory for Lab-dips development as like as original swatch.

After developed of Lab-dips dyeing factory submits for approval from buyer by the Marketing &Merchandiser. Here those shades get the approval from buyer. This shade goes to the bulk production.

Purchase to other accessories, Marketing &Merchandising manager or Merchandiser collect the original sample of all required accessories, Such as zipper, button, main label, size label ,care label, hang tag, price tag, poly, blister& carton from buyer.

Then communicate with the different supplier for sample development. Which accessories factory provide the lower cost and better quality& due time delivery. We order to those accessories factory for required accessories sample development.

After developed the accessories (zipper, button, main label, size label, care label, hang tag, price tag, poly, blister& carton) accessories factory submit for approval from buyer by the Marketing &Merchandiser those shade get the approval from buyer. This shade goes to the bulk production.

After approval sample of yarn and accessories from buyer then Evance Accessories Ltd opened Back-to-Back L/C against master L/C for the accessories supplier. Here, Bank accept 75% Back-to-Back not more.

Process of handling of raw materials:

| Winding dept | Whether sufficient lighting/ventilation | Yes/No | Yes |

| Whether fire extinguisher provided | Yes/No | Yes | |

| Whether first aid box provided | Yes/No | Yes | |

| Whether face mask/cap provided | Yes/No | Yes |

| Knitting Dept | Whether sufficient lighting/ventilation | Yes/No | Yes |

| Whether fire extinguisher provided | Yes/No | Yes | |

| Whether first aid box provided | Yes/No | Yes | |

| Whether ample space between machines | Yes/No | Yes | |

| Whether knitted panels are stored in bins | Yes/No | Yes | |

| Whether proper production & QC records maintained | Yes/No | Yes | |

| No of supervisors per machine | 1/30 |

| Linking dept | Whether sufficient lighting/ventilation | Yes/No | Yes |

| Whether fire extinguisher provided | Yes/No | Yes | |

| Whether first aid box provided | Yes/No | Yes | |

| No of supervisors per machine | 1/26 |

| Washing dept | Whether sufficient lighting/ventilation | Yes/No | Yes |

| Whether fire extinguisher provided | Yes/No | Yes | |

| Whether wshd & pre wshd garments are kept in bins | Yes/No | Yes | |

| Whether proper production & QC records maintained | Yes/No | Yes | |

| Whether workers are provided protective gear | Yes/No | Yes | |

| Whether electric boards & switches protected fm water | Yes/No | Yes | |

| Whether sufficient washing & drying capacity available | Yes/No | Yes |

| Pressing Dept | Whether sufficient lighting/ventilation | Yes/No | Yes |

| Whether fire extinguisher provided | Yes/No | Yes | |

| Whether pressed garments are kept in bins | Yes/No | Yes | |

| Whether proper production records maintained | Yes/No | Yes | |

| Whether first aid box provided | Yes/No | Yes | |

| Whether pressing boards are marked for style & size |

| Mending/Trmg | Whether sufficient lighting/ventilation | Yes/No | Yes |

| Whether pressed garments are kept in bins | Yes/No | Yes | |

| Whether proper production & QC records maintained | Yes/No | Yes |

| QC dept | Whether sufficient lighting/ventilation | Yes/No | Yes | |

| Whether detailed QC records maintained | Yes/No | Yes | ||

| AQL level followed by the fty for inline & final inspections | Inline | 2.5 | ||

| Final | 4.0 | |||

| No of persons in the QC team | 12 |

| Sorting & Pkg | Whether sufficient lighting/ventilation | Yes/No | Yes |

| Whether garments are sorted by shade before ctn pkg | Yes/No | Yes | |

| Whether dept is adequately staffed | Yes/No | Yes | |

| Whether sufficient walking space (aisles) btwn ctns | Yes/No | Yes | |

| Whether ctns are stacked by style, color & size | Yes/No | Yes | |

| Whether high stacks are avoided to prevent crushing | Yes/No | Yes | |

| Whether carton are stacked away from water, oil etc. | Yes/No | Yes |

| Signs & Markings | Whether all depts are properly marked | Yes/No | Yes |

| Whether fire extinguishers are highlighted | Yes/No | Yes | |

| Whether all exits and entrances marked | Yes/No | Yes | |

| Whether electric boards are marked with “CAUTION” | Yes/No | Yes | |

| Whether toilets are marked | Yes/No | Yes | |

| Whether first aid boxes are highlighted | Yes/No | Yes | |

|

| Whether generator & boiler are marked “CAUTION” | Yes/No | Yes |

Price Strategy:

Price list of required raw materials or accessories of sweater in the prospect of Bangladesh:

| Sl N | Item | Unit Value | |||

| 1 | Yarn | ……….. | 11 | Rubber Pullar | $ 0.40/dzn |

| 2 | Woven Main Label | 12 | CASUAL | $ 0.40/dzn | |

| IBT Navy (KIDS) | $ 0.12 | 13 | GREAT STONE | $ 0.45/dzn | |

| TGT Red (Girls) | $ 0.12 | 14 | Zippers | ||

| Great Stone(MENS) | $ 0.14 | Nylon no-5, O/E – Full length | $1.60/dzn | ||

| Young Fashion(LADIES) | $ 0.14 | Vislon no-5, O/E – Full length | $ 2.40/dzn | ||

| 3 | Woven Size Label | $ 0.06/DOZ | Vislon no-5, O/E – half length | $ 1.00/dzn | |

| 4 | Paper Care Label | $ 0.06/DOZ | Nylon no-3, O/E – half length | $ 0.65/dzn | |

| 5 | Printed Price Tag | $ 0.12/DOZ | 15 | Embroidery: | |

| 6 | Rubber Patch | ART(0002)>4.80 unt/dz@0.25 | $ 1.20/dzn | ||

| PVC (Girls) | $ 0.50/DOZ | ‘S’logo(0003)>5 unt/dz@0.25 | $ 1.20/dzn | ||

| Great Stone | $ 0.40/DOZ | 16 | Twill Fabric | $ 1.45/yd | |

| 7 | Woven Badge(AUTHENTIC) | $ 0.48/DOZ | |||

| 8 | Fack leather string | $ 0.05/yd | |||

| 9 | CASUAL | $ 0.10/dzn | |||

| 10 | YOUNG FASHION | $ 0.10/dzn |

Price list of yarn for the running Market:

| SL. No | Description | Yarn COUNT | Price |

| 1 | 100% ACRYLIC | 2/32 ”smm” | 1.35/Lbs |

| 2 | 100% ACRYLIC | 2/36 “Smm” | 1.40/Lbs |

| 3 | 100% BRIGHT ACRYLIC | 2/40 “NM’ | 1.70/Lbs |

| 4 | 100% COTTON(CARDED) | 2/20 “NE” | 2.10/Lbs |

| 5 | 100% COTTON (COMDED) | 2/20 “NE” | 2.20/Lbs |

| 6 | 100% COTTON(COMDED) | 2/30 “NE” | 2.50/Lbs |

| 7 | 100% ACY H/BULK | 2/32 “ smm” | 1.35/Lbs |

| 8 | 100% ACY MELANG | 2/32 ”smm” | 1.70/Lbs |

| 9 | 100% ACY CTNLIKE | 2/26 “NE” | 1.65/Lbs |

| 10 | 100% ACY CTNLIKE | 2/28 “NE” | 1.70/Lbs |

| 11 | 100% ACY-SMILING | 1/9 “NM” | 1.80/Lbs |

| 12 | 100% ACR, CASMERE LIKE | 2/36 “smm” | 2.20/Lbs |

| 13 | 100% ACR, CASMERE LIKE | 2/32 “smm” | 2.10/Lbs |

| 14 | 100% ACY CHENILLE (5 GG) | 1/3.5 “NM” | 1.90/Lbs |

| 15 | 100% COTTON LIKE | 2/28 “NM” | 1.70/Lbs |

| 16 | 100% COTTON LIKE | 2/26 “NM” | 1.70/Lbs |

| 17 | 100% COTTON | 2/32NE | 1.70/Lbs |

| 18 | 50%/50% ACY/CTN(Combed) | 2/20 “NE” | 2.35/Lbs |

| 19 | 50%/50% ACY/CTN(Combed) | 2/30 “NE” | 2.50/Lbs |

| 20 | 50%/50% ACY/WOL( S/D) | 2/32 “smm” | 2.50/Lbs |

| 21 | 50%/50% ACY/WOL (D/D) | 2/32 “smm” | 3.00/Lbs |

| 22 | 85% / 15% ACR /WOL S/D | 2/32 “smm” | 2.25/Lbs |

| 23 | 85% / 15% ACR /WOL D/D | 2/32 “smm” | 2.35/Lbs |

| 24 | 70%/30% ACY/WOL S/D | 2/32 “smm” | 2.30/Lbs |

| 25 | 70%/30% ACY/WOL D/D | 2/32 “smm” | 2.50/Lbs |

| 26 | 70%/30% ACY/WOL S/D | 2/36”smm” | 2.30/Lbs |

| 27 | 70%/30% ACY/WOL D/D | 2/36”smm” | 2.60/Lbs |

| 28 | TWISTING CHARGE(ACRYLIC) | 0.30/Lbs | |

| 29 | TWISTING CHARGE(cotton) | 0.25/Lbs |

Generally As per garments weight, style, yarn types and required accessories based on these finally setting the price of products.

In the following shown how will setting the price of Evance Accessories Ltd in there WIBRA’S running order- Pricing strategy.

Environmentally Requirement:

In the company facility provided ten toilets (5 toilets for male and 5 toilets for female) for the production related personals. These are constructed with well ventilation; floor wall and ceiling with light color, smooth, washable, tiles. Cleaning is done as per schedule, 6 time’s day. Hand washing and hand sanitizing facilities are provided adjacent to the toilets. Such as soap toilet paper. One quality control staffs monitor it before starting of work and within the middle of work and keep records and give in formation to his higher authority when any discrepancy comes to notice. Everybody will have to wash and sanitize their hands after every return from the toilets. In this company are many facilities provided such as, Fire protection, Electricity etc.

Operation:

Process of production:

Sample Section: Buyer given to original sample/sketch /measurement sheet for sample development. If buyer is satisfied on develop sample then buyer give the approval & after setting the price he/she give the order.

Winding section: After receiving the yarn from the dyeing factory (Before bulk production dyeing factory approved by the Lab-dips and three-set of knitting swatch from buyer through buying house or merchandiser).In the Winding section yarn is bobbin. Bobbin size depends on the knitting weight. Generally it is 2½ -3½ Lbs. but requirement of knitting section it could be ½ -4½ Lbs. After this bobbin distributed to the Knitting distribution section. Then knitting distribution section distribute of the bobbin to Knitting section for knitting the garments part by part. After completed the Knitting garments part by part its reach to knitting inspection section for inspection. Then again Knitting garments part by part go back to knitting distribution section.

From here Linking distribution section collect Knitting garments part by part for linking & distributed to the linking operator. After completed the linking operator submit to the linking inspection section. Then garments/products distribute to over lock .After over lock garments go to trimming section including Light Cheque, here Trimming & Light Cheque both section just identity the problem for repairing in the next section its called Mending Section .After Mending garments/products go to the wash section. When wash is completed then products distribute to Iron section. From here garments distribute to sewing section for attached the main label, care label & size label. after completed sewing garments/products go to PQC .here cheque everything for ensure the perfect quality of garments/products under the direct supervision of Quality controller (QC).When PQC department is satisfied on the garments then products go to the Packing/Packaging section. Here garments would be Packing/Packaging by the poly or blister. Then finally cartooned of the garments, based on the ratio which is given from buyer.

Following departments are involved with operation/production in Evance Accessories Ltd:

- Winding section

- Knitting section

- Linking inspection section

- Trimming section

- Mending Section

- wash section

- Iron section.

- sewing section

- PQC

- Packaging section

Required Machinery’s List of Evance Accessories Ltd:

| Sl. | Name of Machine | Gauge | Qty. |

| 01 | 36¢¢ Bed 3.1/28 Flat Knitting Machine (wild-horse) | 3GG | 120 Sets |

| 02 | 36¢¢ Bed 3.1/28 Flat Knitting Machine (wild-horse) | 5GG | 100 |

| 03 | 36¢¢ Bed 3.1/28 Flat Knitting Machine (wild-horse) | 7GG | 100 |

| 04 | Power Driven Dial Linking Machine | 6GG | 50 Sets |

| 05 | Power Driven Dial Linking Machine | 8GG | 68 ¢¢ |

| 06 | Winding Machine | 8 Spindles each | 13 Sets |

| 07 | Washing Machine | 120 Lbs each | 03 Sets |

| 08 | Drying Machine (USA) | 75 Lbs each | 02 Sets |

| 09 | Hydro Extractor | 03 Sets | |

| 10 | Auto Placket Machine | 04 Sets | |

| 11 | Steam Iron | 24 Sets | |

| 12 | Sewing Machine (Juki) | 06 Sets | |

| 13 | Overlook Machine (Juki) | 04 Sets | |

| 14 | Button Hole Machine (Juki) | 01 Set | |

| 15 | Button Stitch (Juki) | 01 Set | |

| 16 | Weighing Scale (Japan) | 02 Nos | |

| 17 | Heavy Weighing Machine (Korea) | 03 Sets | |

| 18 | Boiler (Fulton USA) | 470 kg | 01 Set |

| 19 | Boiler Stand by (Germany) | 01 Ton | 01 Set |

| 20 | Stand by Generator 80 kw. (UK) | 01 Set |

Responsibility:

Based on catalog or by their own innovativeness/ creativity designer could be creating a new design product for sampling. As well as they are developed sample as like as original sample or Sketch or measurement sheet. (Which is given from buyer) for buyer approval.

Effective& efficient as well as innovative or creative design section can bring better result for the company. That’s why Evance Accessories Ltd established the in hose sample production and recruited the high skilled designer and employees for design section.

| Last three years Production | 1998 – 5,18, 400 Pcs |

| 1999– 6,48,000 Pcs | |

| 2000 – 7,00,000 Pcs |

Outbound:

Accessory/ finishing products storage or warehousing system:

| Yarn warehouse | Whether proper records maintained | Yes/No | Yes | |

| Whether sufficient lighting/ventilation | Yes/No | Yes | ||

| Whether ample moving space (aisles) | Yes/No | Yes | ||

| Whether fire extinguisher provided | Yes/No | Yes | ||

| Accessory store | Whether proper records maintained | Yes/No | Yes | |

| Whether sufficient lighting/ventilation | Yes/No | Yes | ||

| Whether ample racks properly marked | Yes/No | Yes | ||

| Whether fire extinguisher provided | Yes/No | Yes |

Packing strategy:

For packing the finishing garments we follow the two type of packing system. It could be Poly or Blister.

Poly : Based on the size, color garments put into the single poly.

Blister: When more then one garments put in together within the poly its called Blister.

After completed Poly or Blister packing section follow the ratio and based on this garments would be cartooned, are the following process:

| Cartoon Ratio |

| Solid Color – Solid Side |

| Solid Color – Assorted Side |

| Assorted Color –Solid Side |

| Assorted Color – Assorted Side |

Technology development:

Cope with changing or technological development:

In fast changing & competitive world, Evance Accessories Ltd started our success winning journey with the most modern machineries from Germany, Japan, and Taiwan manned with highly skilled technical production team having many years practical experience behind them.

Types of technology/ Machinery in use at Evance Accessories factory:

| Sl. | Name of Machine | Gauge |

| 01 | 36¢¢ Bed 3.1/28 Flat Knitting Machine (wild-horse) | 3GG |

| 02 | 36¢¢ Bed 3.1/28 Flat Knitting Machine (wild-horse) | 5GG |

| 03 | 36¢¢ Bed 3.1/28 Flat Knitting Machine (wild-horse) | 7GG |

| 04 | Power Driven Dial Linking Machine | 6GG |

| 05 | Power Driven Dial Linking Machine | 8GG |

| 06 | Winding Machine | 8 Spindles each |

| 07 | Washing Machine | 120 Lbs each |

| 08 | Drying Machine (USA) | 75 Lbs each |

| 09 | Hydro Extractor | |

| 10 | Auto Placket Machine | |

| 11 | Steam Iron | |

| 12 | Sewing Machine (Juki) | |

| 13 | Overlook Machine (Juki) | |

| 14 | Button Hole Machine (Juki) | |

| 15 | Button Stitch (Juki) | |

| 16 | Weighing Scale (Japan) | |

| 17 | Heavy Weighing Machine (Korea) | |

| 18 | Boiler (Fulton USA) | 470 kg |

| 19 | Boiler Stand by (Germany) | 01 Ton |

| 20 | Stand by Generator 80 kw. (UK) |

Training program for operator, when implement a new technology /machinery:

When new technology /machinery would be implement then Evance Accessories Ltd arrange the training program for operator. Although as a BGMEA member our operator/employee joins the several BGMEA training program.

Procurement:

Process of purchasing inputs, such as-materials, supplies and equipment:

After get the order from buyer then Marketing &Merchandising section communicate with the Dying factory& Accessories supplier. And Marketing &Merchandising manager or Merchandiser consumption of Yarn as per buyer order.

Then order to Dyeing factory for Lab-dips development. Here order to those Dying factories which provide the lower cost and better quality& due time delivery. Before Lab-dips order Merchandiser must collect original sample of Yarn / Color swatch / Panton.no from buyer. And given some original swatch to dyeing factory for Lab-dips development as like as original swatch.

After developed of Lab-dips dyeing factory submits for approval from buyer by the Marketing &Merchandiser. Here those shades get the approval from buyer. This shade goes to the bulk production.

Purchase to other accessories, Marketing &Merchandising manager or Merchandiser collect the original sample of all required accessories, Such as zipper, button, main label, size label ,care label, hang tag, price tag, poly, blister& carton from buyer.

Then communicate with the different supplier for sample development. Which accessories factory provide the lower cost and better quality& due time delivery. We order to those accessories factory for required accessories sample development. After developed the accessories (zipper, button, main label, size label, care label, hang tag, price tag, poly, blister& carton) accessories factory submit for approval from buyer by the Marketing &Merchandiser those shade get the approval from buyer. This shade go to the bulk production.

After approval sample of yarn and accessories from buyer then Evance Accessories Ltd opened Back-to-Back L/C against master L/C for the accessories supplier. Here, Bank accept 75% Back-to-Back not more.

Generally Evance Accessories Ltd purchase of inputs-on cash or Back-to-Back L/C. The company is in a position to open Back to Back L/C for import of yarn and raw materials within a couple of days form the date of receipt of Master L/C for execution of the Export orders.

Procurement system/activity:

After get the order from buyer then Marketing &Merchandising section communicate with the Dying factory& Accessories supplier. And Marketing &Merchandising manager or Merchandiser consumption of Yarn as per buyer order.

Then order to Dyeing factory for Lab-dips development. Here order to those Dying factories which provide the lower cost and better quality& due time delivery. Before Lab-dips order Merchandiser must collect original sample of Yarn / Color swatch / Panton. no from buyer. And given some original swatch to dyeing factory for Lab-dips development as like as original swatch.

After developed of Lab-dips dyeing factory submits for approval from buyer by the Marketing &Merchandiser. Here those shades get the approval from buyer. This shade goes to the bulk production.

After bulk production dying factory delivery of the yarn to Evance factory at Mirpur.

After receiving the yarn from the dyeing factory, then factory activity will start from the winding section and section by section it will be proceed for the finishing products. Within this production schedule Merchandiser follow-up the daily production report because of the due time shipment.

And arranged to other required accessories .For this collect the original sample of all required accessories, Such as zipper, button, main label, size label, care label, hang tag, price tag, poly, blister& carton from buyer. Then communicate with the different supplier for sample development. Which accessories factory provide the lower cost and better quality& due time delivery. We order to those accessories factory for required accessories sample development.

After developed the accessories (zipper, button, main label, size label, care label, hang tag, price tag, poly, blister& carton) accessories factory submit for approval from buyer by the Marketing &Merchandiser those shade get the approval from buyer. This shade goes to the bulk production.

After bulk production accessories factory delivery all accessories to Evance factory within the given time.

Evance Marketing & Merchandising section follow-up and monitor the all activities of Production on daily basis. and time to time communicate with the buyer about the production as well as the due time shipment or if any other incidental situation will happen.

Financial policy & financial supporters of Evance Accessories Ltd.:

As a sweater factory or Buying house Evance Accessories Ltd maintain there financial policy based on the Master L/C against Back-to-Back L/c. Actually Evance Accessories Ltd working as like as dealer. Master L/C depends on the buyer.

Production:

Standard production capacity of each section in daily basis:

| Critical Style(Pcs) | Simple Style(Pcs) | /Per Operator | /Per Operator | ||

| Sample Section | 3-4 Pcs | 16 Pcs | |||

| Winding | Cotton/Acrylic 180-250 Lbs/P.O | Chenille 100-120 Lbs/P.O | |||

| Knitting |

| ||||

| Linking | 1000-1100 | 1800-2000+ | |||

| Trimming | Normal 18-20 Doz/P.O | Critical 3 Doz/P.O | |||

| Light Cheque | 1000 Pcs/P.O | 700-800 Pcs/P.O | |||

| Mending | 15-20 Doz/P.O | 5-6 Doz/P.O | |||

| Wash | 1500-2000 | 2800-3000 |

| ||

| Iron | If, Linking & Knitting is ok, |

| |||

| Then, 3000+ | |||||

| Swing | 500 Pcs | 700-800 Pcs | |||

Standard production capacity of finishing products in monthly basis:

| Present Production Capacity

| 75,000 pcs/Month (3, 5 & 7 Gauges). |

| 3gg | 30,000 Pieces |

| 5gg | 25,000 Pieces |

| 7gg | 20,000 Pieces |

Stakeholder:

Process of Selecting the suppliers and name of them:

After get the order from buyer then Marketing &Merchandising section communicate with the Dyeing factory& Accessories supplier for Lab-dips & sample development. After approval of Lab-dips & required accessories sample from buyer. Then order for bulk production. Here order to those Dying factory& Accessories supplier those provide the lower cost, better quality& due time delivery.

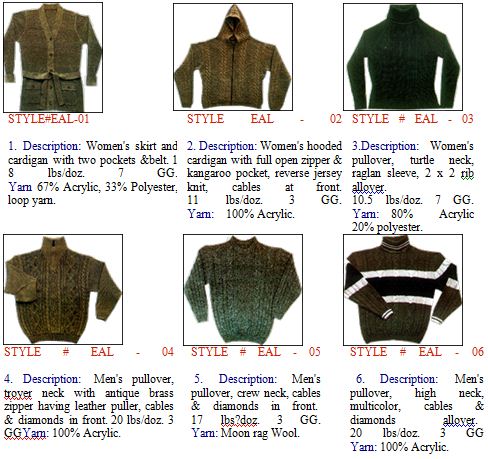

Products of Evance:

The products of the project are extremely well received owing their superb quality reasonable prices & maintenance of delivery schedule. Products covering children’s, men’s, women’s, sweater-pullover, cardigan, vest, skirt, overcoat & poncho etc. in any stitches, designs with different types of yarns like Acrylic, Wool, Cotton, Angora, Boucle, Chenille, Popcorn, Lambs wool, Shetland wool, Mohair, Filigree, loop yarn, Smiling, T.T. Viscose, Poodle yarn, Lycra, different mixed and fancy yarns.

In House Sample Production:

We arrange required yarns/fabrics/accessories as per requirements of our valued buyers and provide samples on specific queries in a very quicker way to support their sales campaigns. All this and much more is a part of our concept.

Service & quality:

So far we have been working with different foreign buyers of Denmark, Belgium, France, Germany, UK, Holland & many other countries to feed back our own manufacturing unit Evance Accessories Ltd and planning to split orders to our associate industries.

If you have a specific query on us we can offer you our services in the following manner:

1) Providing you required customer samples & salesman samples on your specific orders Queries.

2) Offering you our best workable prices on the samples.

3) Execution of your export orders maintaining delivery schedule, Follow-up all the steps in the production, keeping you informed about current status of your orders, checking of measurements, weight of garments as per measurements / spec sheet ultimately issuing pre-shipment inspection certificate for & on your behalf.

Place all your orders for Bangladesh through our company and you will get a lot of service and support.

- Providing you samples as per your requirement with best price.

- Execute export orders maintaining delivery schedules as specified in the L/C.

- Arranging yarns & accessories as per requirement of the buyers.

- Checking of measurements weight as per spec. sheets & order sheets during the production.

- Quality Control from a very early start.

- Our Quality team is directly responsible to the management for perfect quality.

- Follow up on all steps in the production.

- Keeping you informed about status of your orders.

No goods leave the factory without perfect quality checking & approval from the proper authority.

Maintain standard Quality:

With our continued and hardworking efforts in maintaining standard quality of the Finished garments our perfect quality checking methods directly responsible to the management will certainly meet the customer’s satisfaction. Method consists of following forms:

- 1st inspection after knitting the finished garment parts & rectification,

- 2nd inspection after trimming with light checking & rectification.

- 3rd inspection & rectification after wash iron and then final inspection (P.Q.C) for perfect quality checking & rectification

We never compromise with the above for maintaining our goodwill and reputation. We are committed to timely shipment, maintaining 100% fine quality, strict quality control at every stage of production, responding fast to constantly changing demands.

Marketing strategy for buyer:

Marketing strategy for selected buyer or existing buyer including with time-to-time communicate with them and try to fulfill all requirement in each order for keeping the long term relationship.

Marketing strategy for potential buyer:

At first, Communicate with the potential buyer by issued Business development letter including complete profile of the factory, By this letter Evance Accessories Ltd offer to buyer for factory evaluation .After this on suitable time of buyer he/she visit the factory. If buyer satisfied on the factory then have a chance to getting order from buyer, if other activities are happen positively.

Identified consumers needs then produced/delivered product:

First Evance Accessories Ltd identified consumer’s needs then produced/delivered product. In garments business identified consumers needs or requirement is very important.

Market segmentation of Evance Accessories Ltd:

Evance Accessories Ltd has done market segmentation. By the market segmentation they choose their market in European Union member’s country. Main reasons of those market selections are – available buyer is there and they provide/offer the better price.

| Dr.Rehfeld, NKD, Kik, KarlRicker, Compesia Ltd (Chepou), Golden Penny | Germany |

| Vegotex | Belgium |

| Safico, CoraCasino, Opera, Vetura, Creeks, Megatrade, Complices | France |

| Holm | Denmark |

| Rex & Peacock | U.K |

| Jeans Centre, Wibra Supermarket | Netherlands |

| New York | USA |

Export Performance (Sweater) of Evance Accessories Ltd. (2004)

| Month | Quantity | Value |

| January-2004 | 16,096 | $ 41,060.32 |

| February-04 | 20,320 | $ 76,320.00 |

| March-04 | 42921 | $ 98,398.60 |

| Appril-04 | 32120 | $ 100123.00 |

| May-04 | 35472 | $ 117812.10 |

| June-04 | 31081 | $ 91904.46 |

| July-04 | 38112 | $ 163231.60 |

| August-04 | 77180 | $ 326155.00 |

Statement of Profit & Loss for the Year July 2003 to June 2004

A. Gross Profit : TK. 26.75 LAC

B. Net Profit : TK. 11.14 LAC

Cumulative Loss on 30.05.2004: TK. 138.38 LAC

Competitive advantage of Evance Accessories Ltd.:

With our continued and hardworking efforts in maintaining standard quality of the Finished garments our perfect quality checking methods directly responsible to the management will certainly meet the customer’s satisfaction. Method consists of following forms

1st inspection after knitting the finished garment parts & rectification,

2nd inspection after trimming with light checking & rectification.

3rd inspection & rectification after wash iron and then final inspection (P.Q.C) for perfect quality checking & rectification.

We never compromise with the above for maintaining our goodwill and reputation. We are committed to timely shipment, maintaining 100% fine quality, strict quality control at every stage of production, responding fast to constantly changing demands.

We are managing all the paper work, supervising the production from start to end and shipping the goods in accordance with your instructions

Customer Relationship Management (CRM) in practice:

To build up relation with potential buyer: At first, Communicate with the potential buyer by issued Business development letter including complete profile of the factory, By this letter Evance Accessories Ltd offer to buyer for factory evaluation .After this on suitable time of buyer he/she visit the factory. If buyer satisfied on the factory then Buyer given to original sample/sketch /measurement sheet for sample development. if buyer is satisfied on develop sample .Then buyer give the approval & After setting the price he/she give the order .

Within this time or in the shipment time several activities will happen &would be required several times to correspondence with buyer. By this correspondence day by day grow up a relation with buyer.

Buyer fined of Evance Accessories Ltd:

From e-mail account eal@dhaka.net, Internet, BGMEA catalog, FAX, Telephone, mobile, company brochure etc. Based on the previous performance, better quality, better price offering and maintaining delivery schedule.

Marketing strategy for off season:

For off season Marketing technique for Evance Accessories Ltd are-In the off season find out the buyers ( basically those are given the order in off season).It would be lower price. Another off season marketing technique is Subcontract base order shipment. Only for odd season or when our factory is free or hasn’t better order in our hand just these time Evance Accessories Ltd respond to lower price offering buyers.

Reason for stock goods:

Some of the reason that’s affect for stock goods. These are the following:

- Over shipment date or failed to shipment date.

- Bad quality or when by the quality company cannot meet the buyer requirement.

- Sometimes over shipment date buyer will agree/proposal for air shipment .But total cost & charge of air shipment should be bear of those factory. May be it is better than stock.

Promotional technique of Evance Accessories Ltd:

Evance Accessories Ltd is a 100% Export oriented Garments manufacturer/exporters and buying agent of Garments having good linkage program with garments industries to support import program from Bangladesh. For selling the stock goods, first our Marketing people communicate with the stock buyer. Then provide sample including Packing list & Price to the stock buyer . If buyer accepts it then stock could be selling.

Procedure of after products delivered:

After delivered /shipment of products (sweater) Evance accessories Ltd submit commercial document to negotiation bank for payment against Master L/C (Letter of Credit).Commercial document including as per L/C requirement. Such as – bill of exchange, Invoice, GSP, Packing list, C/O, B/L (Bill of leading), Beneficiary Certificate, Inspection Certificate, and EXP.

Recommendation:

I would like to Recommend on the following areas that’s should be help to achieve the goals of Evance Accessories Ltd. Basically I give the more emphasis on marketing and as well as the total activities.

- A marketer can rarely satisfy everyone in a market. So, First task of Evance Accessories Ltd. marketing department must be market segmentation and identity these market which present the greatest opportunity for them .Then setting their target market , after that for each chosen market Evance Accessories Ltd. develops their market offering.

- Evance Accessories Ltd. marketing department must try to understand the buyer needs, wants and demands.

- Develop the long term relationship with key parties- buyers, buying house and suppliers.

- Evance Accessories Ltd. management to build a marketing program to achieve the desires objectives. To achieve the objectives set the effective marketing mix (product, price, promotion and place).

- To achieve the ultimate objectives, it’s very essay to follow the proper marketing concept.

- That’s will better for Evance Accessories Ltd. to work with repeat buyer than new buyer. Because one estimate is that attracting a new customer can cost 5 times as much as pleasing an existing one. Also, it might cost 16 times as much to bring the new buyer to the same level of profitability as the lost buyer.

- So, customer retention is thus more important than customer attraction.

- I request to Evance Accessories Ltd. to follow modern-customer orientation-organization chart then traditional organization chart.

- Hopefully Evance Accessories Ltd. define their mission .I would like to say you can shared your mission statement with manager, employees. A clear mission statement guides the employee to work independently and yet collectively toward realizing the organizational objectives.

- Today’s business world moving very first by the digital revolution. The impact of these Evance Accessories Ltd. can implement the data based marketing.

- Survey on buyer intentions regarding plant, equipment and raw materials.

- Take an expert opinion regarding garments business.

- Identify their position based on the product life cycle and position of their competitors, and then take a corrective action.

- Evance Accessories Ltd. can developed their design section by create the innovative and unique products design for the marketing. For this purpose you can contract with a professional fashion designer in Bangladesh & abroad.

- You can improve your procurement department for the better coordination with other section.

- You can set the effective promotional tools for buyer awareness about your business. In this purpose Evance Accessories Ltd. can rearrange their web site and including more information about Evance Accessories Ltd.

- In garments business relationship marketing should be very much effective, Evance Accessories Ltd. can follow this style.

- Build a sound relation with marketing department to others department.

- As early as possible you will implement HRM department for your business. It could be bring better result for you.

- Evance Accessories management team can recruit the effective & efficient employee for their business. And ensure its-‘right people for the right position’.

- Allow employees to participate decision making that affect them .They can increase productivity, commitment to works.

- Guide rather than order. Set a good example, the top management set the style for his people. Subordinates always watching their boss. Be a person worth coping.

- Reward should be contingent on performance.

- It’s helps organizations deals with globalize and deregulated capital markets.

- Its helps to balance short-term, mid-term and long term trade off.

- If you follow the value chain management, it could be improves the allocation of recourses, streamlines planning and budgeting.

Conclusion:

The firm’s success depends not only on how well each department performs its work, but also on how well the various departmental activities are coordinated.

The linkages between activities are crucial for corporate success. The linkages are flows of information, goods and services, as well as systems and processes for adjusting activities.

Their importance is best illustrated by the Evance Accessories Ltd. example:

If, Only Evance Accessories Ltd. Marketing section delivers the order & shipment forecasts for the next period to all other departments in time and in reliable accuracy, procurement will be able to order the necessary raw materials or accessories for the correct date. And only if procurement does a good job and forwards order information to inbound logistics, only than operations will be able to schedule production in a way that guarantees the delivery of products in a timely and effective manner – as pre-determined by marketing.

In the result, this company vision is to provide the maximum satisfaction to our customers through continuous improvement of operational efficiency, cost effectiveness, latest design and talents of our work force.

This discussion reviews the management of advocates to align strategy, finance, information flow, human systems and decision-making processes to achieve the greatest value for the Evance Accessories Ltd buyers.